Method for preparing 2-(trifluoromethoxy) benzene sulfonamide

A technology of trifluoromethoxyl and benzenesulfonamide, which is applied in the field of preparation of 2-benzenesulfonamide, can solve the problems affecting the quality of the final product, low product yield, ammonia gas harming the environment and human health, and achieves a feasible process , high product purity, good environmental effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

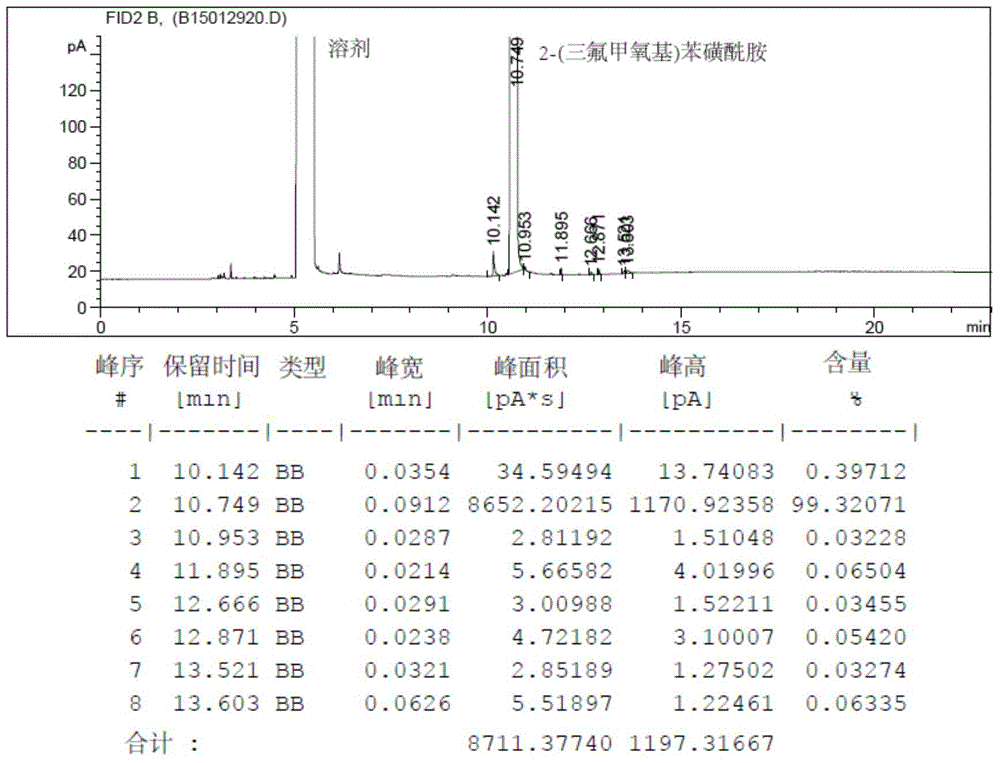

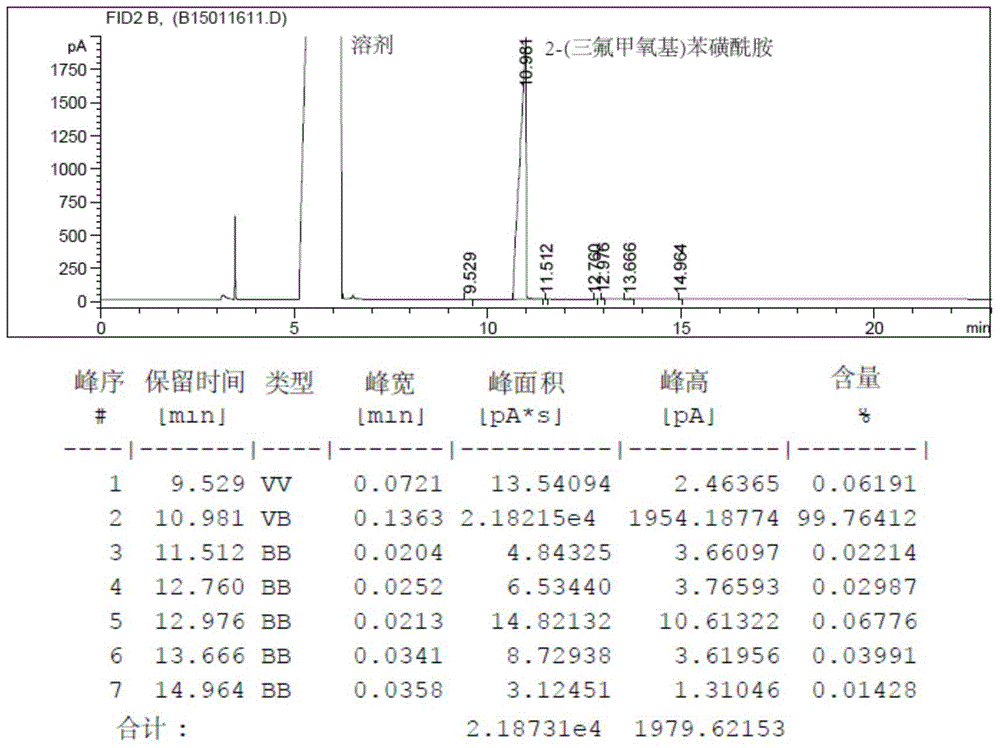

Embodiment 1

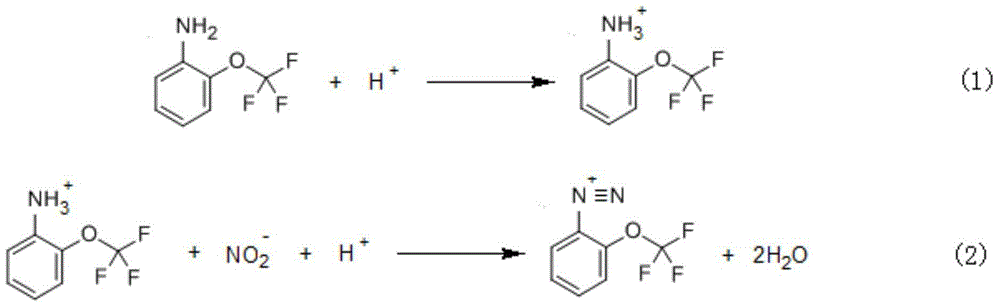

[0049] 1. The preparation of 2-(trifluoromethoxy)aniline hydrochloride:

[0050] In a 1000mL four-necked flask, add 200g (1.92mol) of hydrochloric acid, 100g (0.565mol) of o-amino(trifluoromethoxy)benzene and 80g of water in sequence at room temperature, stir for 1 hour, and control the reaction temperature at 0-30°C. 380 g of a salt-forming reaction solution containing 2-(trifluoromethoxy)aniline hydrochloride was obtained.

[0051] ② Preparation of 2-(trifluoromethoxy)benzenediazonium salt:

[0052] Under stirring, add 120g (0.579mol) sodium nitrite aqueous solution dropwise to the 380g salt-forming reaction solution obtained in step ①, the reaction temperature is controlled at -20~5°C, the dropwise addition is completed in 1h, and the temperature is kept for 1h to obtain 500g of sodium nitrite containing 2 -Diazotization reaction solution of (trifluoromethoxy)benzene diazonium salt.

[0053] ③The preparation of 2-(trifluoromethoxy)benzenesulfonyl chloride:

[0054] In a ...

Embodiment 2

[0059] 1. The preparation of 2-(trifluoromethoxy) aniline sulfate:

[0060] In a 1000mL four-necked flask, add 62.2g (0.622mol) of concentrated sulfuric acid, 100g (0.565mol) of o-amino(trifluoromethoxy)benzene and 100g of water in turn at room temperature, stir for 1 hour, and control the reaction temperature at 80-100 °C, 262 g of a salt-forming reaction solution containing 2-(trifluoromethoxy)aniline sulfate was obtained.

[0061] ② Preparation of 2-(trifluoromethoxy)benzenediazonium salt:

[0062] Under stirring, add 385g (0.678mol) potassium nitrite aqueous solution dropwise to the 262g salt-forming reaction solution obtained in step ①, the reaction temperature is controlled at 40-50°C, the dropwise addition is completed in 3h, and the temperature is kept for 1h to obtain 646g The diazotization reaction solution of (trifluoromethoxy)benzene diazonium salt.

[0063] ③The preparation of 2-(trifluoromethoxy)benzenesulfonyl chloride:

[0064] In a 2000mL four-neck bottle, ...

Embodiment 3

[0068] 1. Preparation of 2-(trifluoromethoxy)aniline phosphate:

[0069] In a 1000mL four-neck flask, add 651g (5.65mol) of phosphoric acid and 100g (0.565mol) of o-amino(trifluoromethoxy)benzene at room temperature, and stir for 1 hour. The reaction temperature is controlled at 50-60°C to obtain 750g of Salt-forming reaction solution of 2-(trifluoromethoxy)aniline sulfate.

[0070] ② Preparation of 2-(trifluoromethoxy)benzenediazonium salt:

[0071] Under stirring, add 117g (0.566mol) sodium nitrite aqueous solution dropwise to the 750g salt-forming reaction solution obtained in step ①, the reaction temperature is controlled at 45-50°C, the dropwise addition is completed in 2h, and the temperature is kept for 1h to obtain 867g containing 2- The diazotization reaction solution of (trifluoromethoxy)benzene diazonium salt.

[0072] ③The preparation of 2-(trifluoromethoxy)benzenesulfonyl chloride:

[0073] In a 2000mL four-necked bottle, add 117g (1.13mol) of hydrochloric acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com