Preparation method of hollow cobaltosic oxide microball materials and application for manufacturing electrodes

A technology of cobalt tetroxide microspheres and cobalt tetroxide, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., can solve the problems of increasing process complexity, product shape damage, and increasing costs, and achieve uniform size and good shape , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Cobalt acetate and sodium acetate were made into 50g / L cobalt acetate solution and 60g / L sodium acetate solution with deionized water respectively. Take one liter of each of the two solutions, put them into a constant temperature water bath at 45°C and add them for 5 minutes, then take 50mL of 28% ammonia solution per liter of solution and pour them into the above mixed solution, stir evenly to obtain The cobalt-ammonia complex solution, and then pour 30mL of hydrogen peroxide per liter into the mixed solution, transfer the solution to a hydrothermal device for treatment, and set the temperature at 110°C for 9 hours. After the reaction was completed, the obtained black precipitate was washed and centrifuged three times with deionized water and absolute ethanol respectively, and dried in an air drying oven for 10 hours to obtain the tricobalt tetroxide product.

[0030] Evenly mix the product with acetylene black and PTFE binder at a mass ratio of 75:10:15, coat the mixe...

Embodiment 2

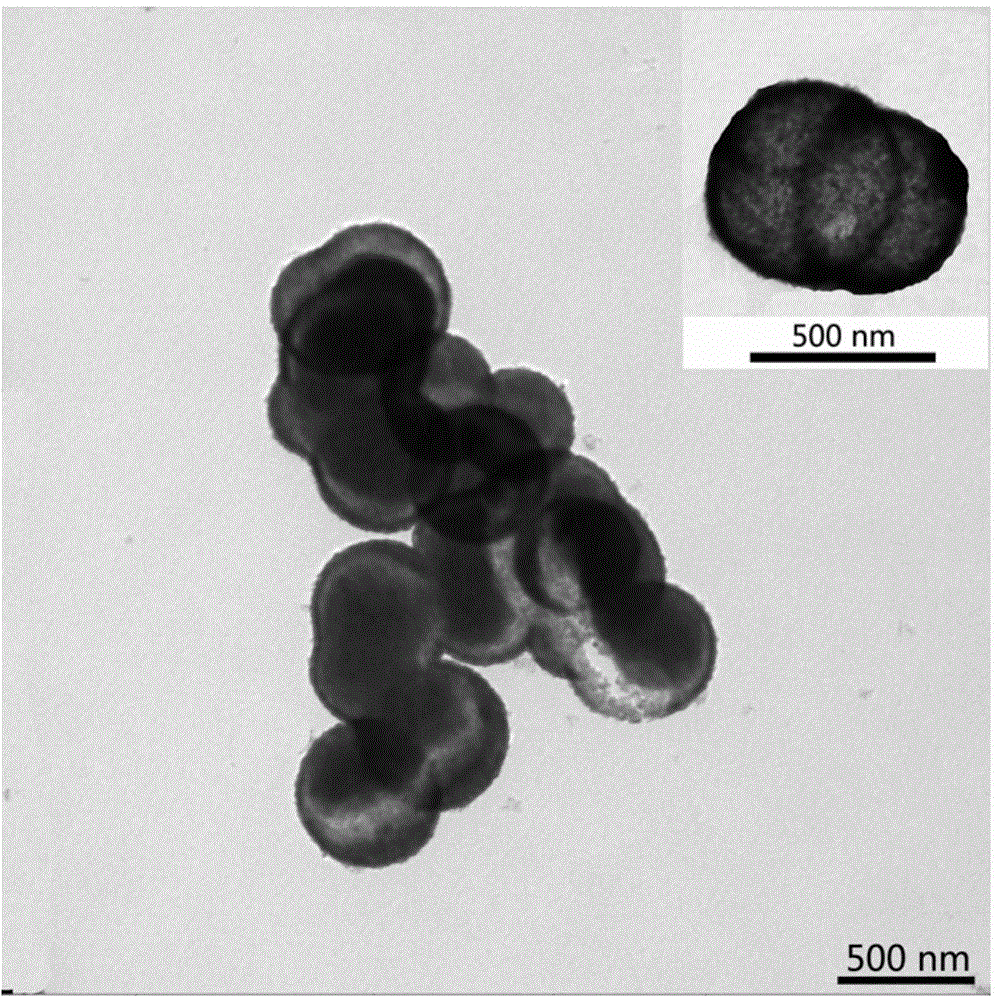

[0032] Cobalt nitrate and sodium nitrate were made into 120g / L cobalt nitrate solution and 100g / L sodium nitrate solution with deionized water respectively. Take one liter of each of the two solutions, put them into a constant temperature water bath at 50°C and add them for 8 minutes, then take 100mL of 28% ammonia solution per liter of solution and pour them into the above mixed solution, and stir evenly to obtain sodium salt-containing Cobalt ammonium complex solution, and then pour 60mL of hydrogen peroxide into the mixed solution per liter of solution, transfer the solution to a hydrothermal device for treatment, set the temperature at 120°C for 10 hours. After the reaction was completed, the obtained black precipitate was washed and centrifuged three times with deionized water and absolute ethanol respectively, and dried in an air drying oven for 8 hours to obtain hollow cobalt trioxide microspheres with a diameter of 500 nm and a thin wall thickness of about 50nm.

[00...

Embodiment 3

[0035] Cobalt nitrate and sodium nitrate were made into 200g / L cobalt nitrate solution and 150g / L sodium nitrate solution with deionized water respectively. Take one liter of each of the two solutions, put them into a constant temperature water bath at 50°C and add them for 10 minutes, then take 150mL of 28% ammonia solution per liter of solution and pour them into the above mixed solution, and stir evenly to obtain sodium salt-containing Cobalt ammonium complex solution, and then pour 90mL of hydrogen peroxide into the mixed solution per liter of solution, transfer the solution to a hydrothermal device for treatment, set the temperature at 160°C for 12 hours. After the reaction was completed, the obtained black precipitate was washed and centrifuged three times with deionized water and absolute ethanol respectively, and dried in an air drying oven for 8 hours to obtain the tricobalt tetroxide product.

[0036] Evenly mix the product with acetylene black and PTFE binder at a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Diameter size | aaaaa | aaaaa |

| Thin wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com