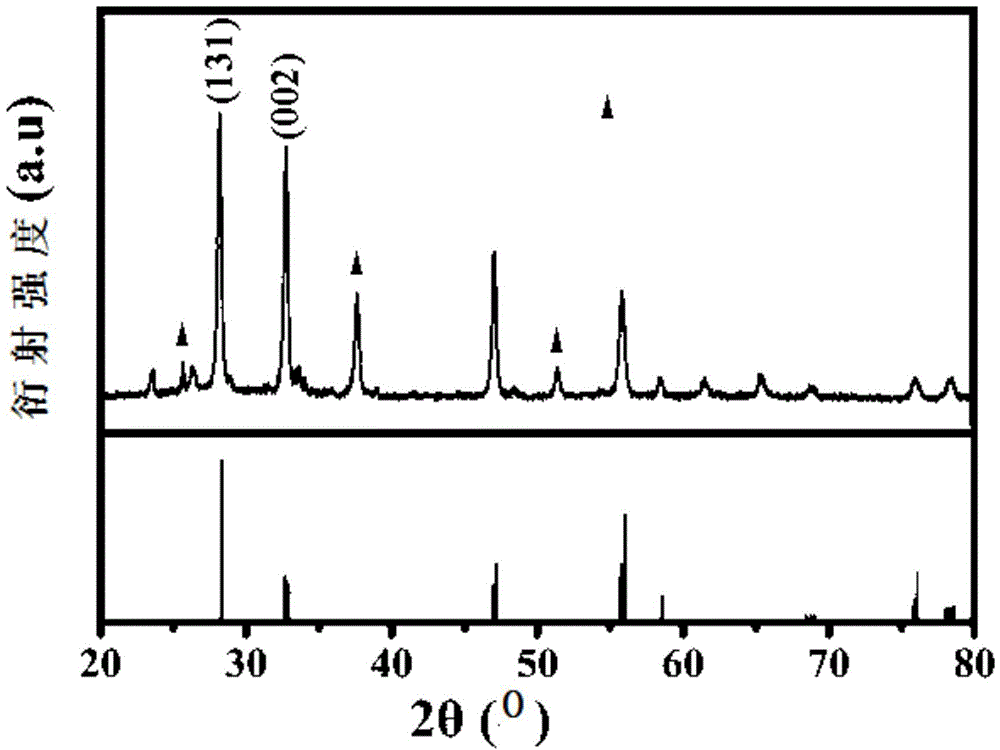

Bismuth tungstate nano-film with photocatalytic performance as well as preparation method and application thereof

A nano-film, bismuth tungstate technology, applied in chemical instruments and methods, nanotechnology, physical/chemical process catalysts, etc., can solve problems such as unfavorable electron conduction, high ion exchange temperature, and long exchange time, and achieve controllability Strong, short reaction time, simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

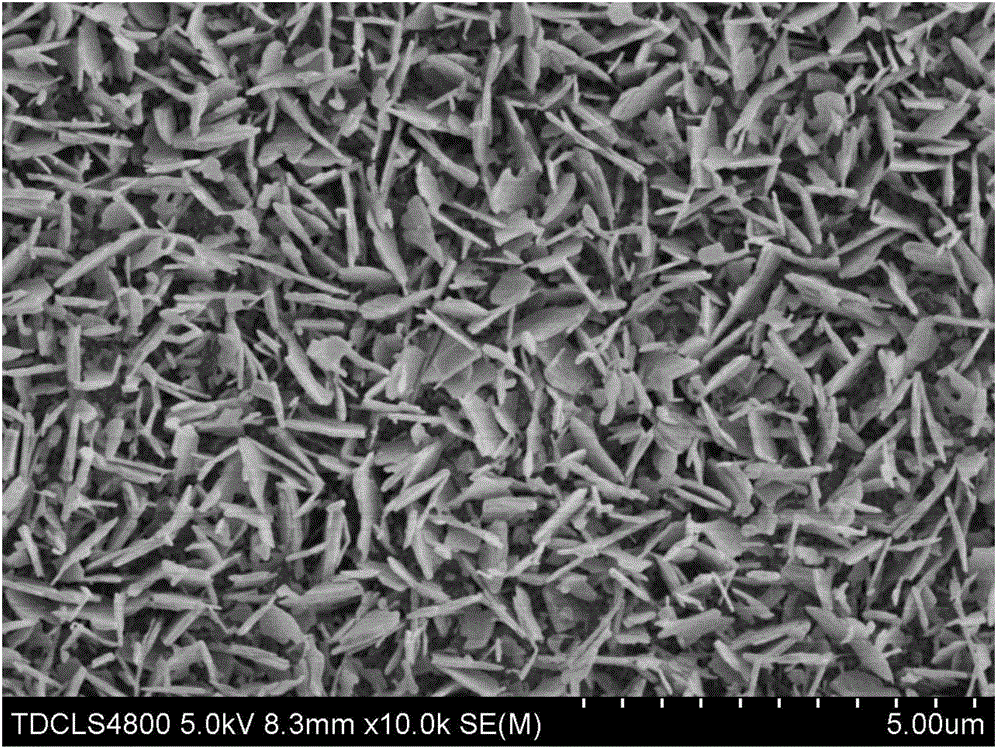

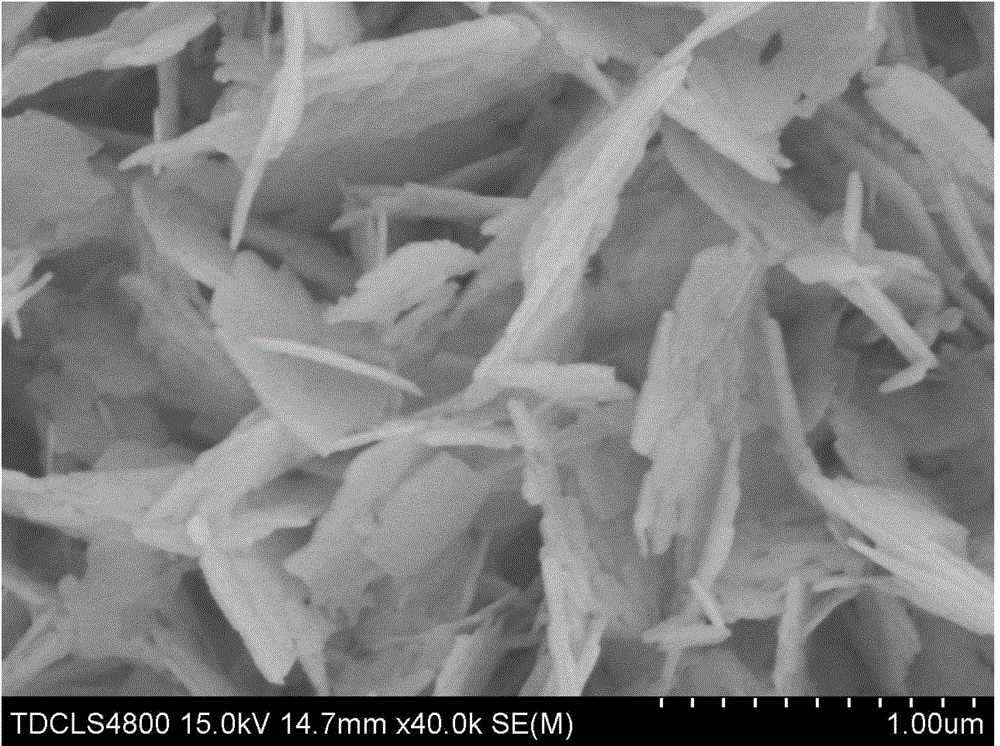

[0024] Embodiment 1-9 is Bi of different specifications described in the present invention 2 WO 6 Preparation method of nano film

Embodiment 1

[0026] (1) Preparation of Bismuth Oxyiodide Nanosheet Precursor Solution

[0027] a) Sonicate the FTO conductive glass successively in deionized water, acetone and ethanol solution for 10 minutes, wash it with deionized water, and dry it for later use;

[0028] b) Add 3.32g of potassium iodide powder and 0.9702g of bismuth nitrate powder into 60mL of deionized water, and adjust the pH to 1.7 with commercial concentrated nitric acid with a volume fraction of 65-68%, and finally obtain a concentration of 0.04moL / L's bismuth oxyiodide nanosheet precursor solution.

[0029] (2) Preparation of bismuth oxyiodide nanosheet thin film

[0030] The cathodic electrodeposition step was performed using a standard three-electrode setup. The FTO conductive glass was used as the working electrode, the platinum sheet electrode was used as the counter electrode, and the silver / silver chloride electrode was used as the reference electrode. The precursor solution of bismuth oxyiodide nanoshee...

Embodiment 2

[0036] (1) Preparation of Bismuth Oxyiodide Nanosheet Precursor Solution

[0037] a) Sonicate the FTO conductive glass successively in deionized water, acetone and ethanol solution for 10 minutes, wash it with deionized water, and dry it for later use;

[0038] b) Add 1.66g of potassium iodide powder and 0.4851g of bismuth nitrate powder into 60mL of deionized water, and adjust the pH to 1.7 with commercial concentrated nitric acid with a volume fraction of 65-68%, and finally obtain a concentration of 0.02moL / L's bismuth oxyiodide nanosheet precursor solution.

[0039] (2) The preparation of bismuth oxyiodide nanosheet thin film is the same as that in Example 1.

[0040] (3) Bi 2 WO 6 The preparation of nano film is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com