Lithium ion battery cathode material and preparation method thereof

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of lower operating voltage platform of lithium ion batteries, no lithium ion insertion and insertion performance, poor cycle performance, etc. Excellent battery cycle performance, improved energy density, and a wide range of charge and discharge voltages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

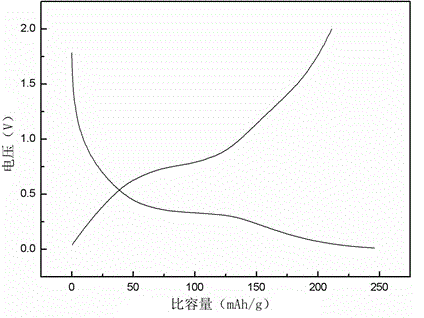

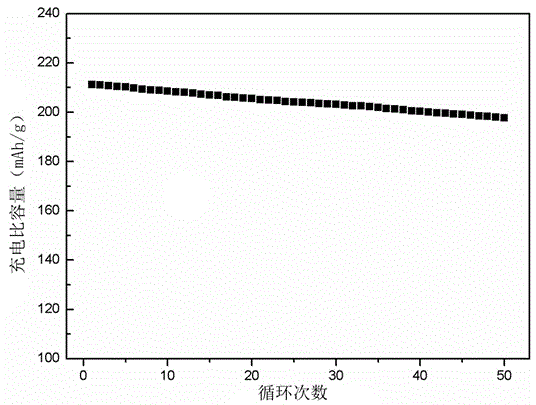

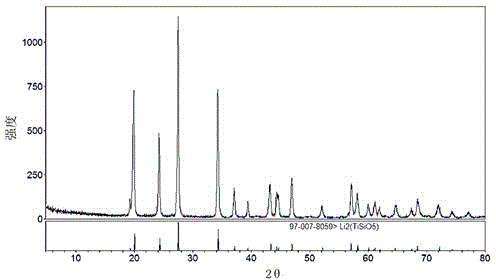

[0029] A kind of negative electrode material of lithium ion battery of the present invention, its chemical formula is Li 2 TiSiO 5 , the reversible capacity of the charge and discharge process is greater than 180mAh / g, the platform of the delithiation process is 0.68V, the platform of the lithium insertion process is 0.35V, the charge and discharge voltage range is 0.01-2.0V, and the specific capacity of the first charge is 211.2mAh / g.

[0030] A preparation method of the lithium-ion battery negative electrode material of the present embodiment comprises the following steps: taking 8.1790 g of tetrabutyl titanate and 5.053 g of tetraethyl orthosilicate and dissolving them in 200 ml of ethanol, and then adding 3.5138 g of Triethanolamine forms solution A. Weigh 4.9998g of lithium acetate and dissolve it in a mixed solution of 100ml of ethanol and 5ml of water to form solution B. Slowly add A to the mixed solution of B during the process of constant stirring to obtain a white ...

Embodiment 2

[0033] A kind of negative electrode material of lithium ion battery of the present invention, its chemical formula is Li 2 TiSiO 5 , the reversible capacity of the charge and discharge process is greater than 180mAh / g, the platform of the delithiation process is 0.72V, the platform of the lithium insertion process is 0.28V, the charge and discharge voltage range is 0.01-2.0V, and the specific capacity of the first charge is 215.6mAh / g.

[0034] A preparation method of the lithium-ion battery negative electrode material of the present embodiment, comprising the following steps: taking 5.4823g of tetraethyl titanate and 3.7305g of tetraethyl titanate and dissolving them in 200ml of ethanol, and then adding 1.8851g of oxalic acid Solution A is formed. Weigh 1.6571g of lithium nitrate and dissolve it in a mixed solution of 100ml of ethanol and 5ml of water to form solution B. Slowly add A to the mixed solution of B during the process of constant stirring to obtain a white sol, c...

Embodiment 3

[0037] A kind of negative electrode material of lithium ion battery of the present invention, its chemical formula is Li 2 TiSiO 5 , the reversible capacity of the charge and discharge process is greater than 180mAh / g, the platform of the delithiation process is 0.75V, the platform of the lithium insertion process is 0.32V, the charge and discharge voltage range is 0.01-2.0V, and the specific capacity of the first charge is 207.8mAh / g.

[0038] A preparation method of the lithium-ion battery negative electrode material of the present embodiment, comprising the following steps: dissolving 6.8308g of titanium tetraisopropoxide and 0.3294g of methyltriethoxysilane in 200ml of ethanol, and then adding 2.078g triethanolamine to form solution A. Weigh 4.3451g of lithium oxalate and dissolve it in a mixed solution of 100ml of ethanol and 5ml of water to form solution B. Slowly add A to the mixed solution of B while stirring continuously to obtain a white sol. Continue to stir, (st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com