Molybdate-based red phosphor powder for white LED and preparation method thereof

A technology of red fluorescent powder and molybdate, which is applied in the direction of chemical instruments and methods, luminescent materials, electrical components, etc., can solve the problems of complex preparation process, unstable performance, high color temperature, etc., and achieve simple preparation process, low equipment requirements, The effect of low sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

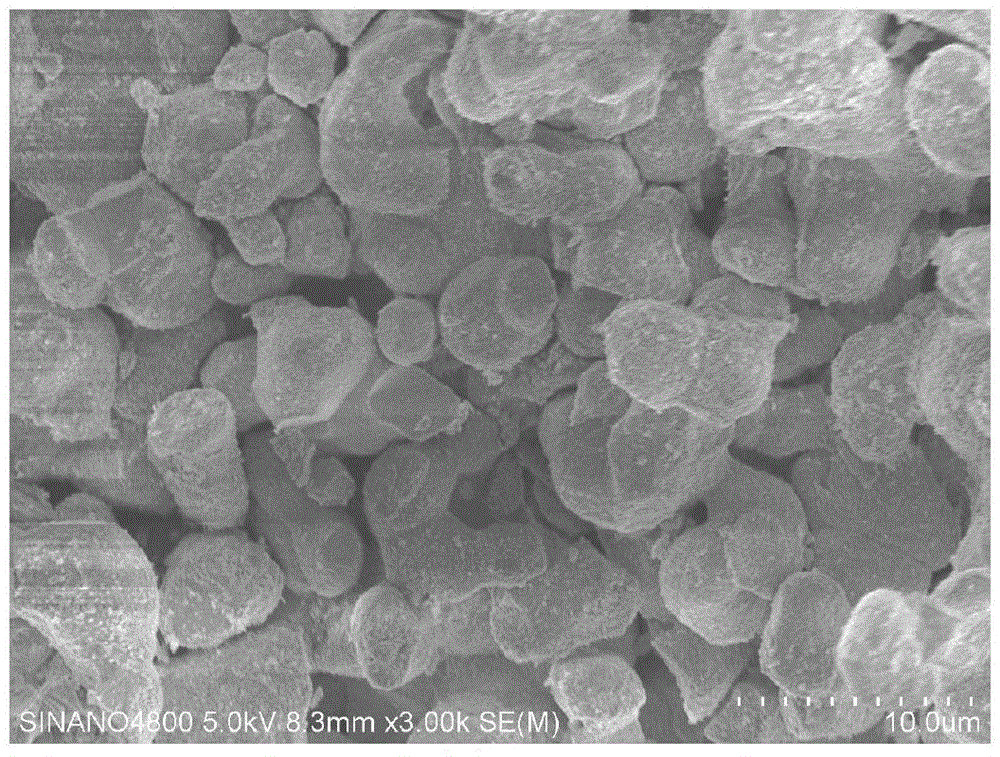

Embodiment 1

[0035] Preparation of Na 1.9 Eu 0.1 Zn 2 Mo 2 o 9 , according to the chemical formula Na 1.9 Eu 0.1 Zn 2 Mo 2 o 9 The stoichiometric ratio of each element in the formula is weighed separately: sodium carbonate Na 2 CO 3 : 0.504 grams, zinc oxide ZnO: 0.814 grams, ammonium molybdate (NH 4 ) 6 m O7 o 24 .4H 2 O: 1.766 g, europium oxide Eu 2 o 3 : 0.088g. After grinding and mixing evenly in an agate mortar, the first pre-sintering is carried out in the air atmosphere of the muffle furnace. The pre-sintering temperature is 400 ° C, and the pre-sintering time is 5 hours. The second pre-sintering is carried out under the parameters; after cooling to room temperature, the sample is taken out, the mixture is fully mixed and ground evenly, and calcined in the air atmosphere, the calcination temperature is 600°C, and the calcination time is 12 hours, then the temperature is lowered to 250°C and kept warm After 6 hours, it was cooled to room temperature, and the sample ...

Embodiment 2

[0042] Preparation of Na 1.6 Eu 0.4 Zn 2 Mo 2 o 9 , according to the chemical formula Na 1.6 Eu 0.4 Zn 2 Mo 2 o 9 The stoichiometric ratio of each element in the formula is weighed separately: sodium carbonate Na 2 CO 3 : 0.424 g, zinc oxide ZnO: 0.814 g, molybdenum oxide MoO 3 : 1.44 g, europium oxide Eu 2 o 3 : 0.352 g. After grinding and mixing evenly in an agate mortar, pre-sintering is carried out in an air atmosphere in a muffle furnace. The pre-sintering temperature is 500°C, and the pre-sintering time is 1 hour. Mix and grind evenly, then calcine in the air atmosphere, the calcination temperature is 900°C, the calcination time is 1 hour, then slowly lower the temperature to 400°C and keep it warm for 2 hours, then cool to room temperature, take out the sample and grind it evenly to get powdered molybdic acid Salt-based red phosphor.

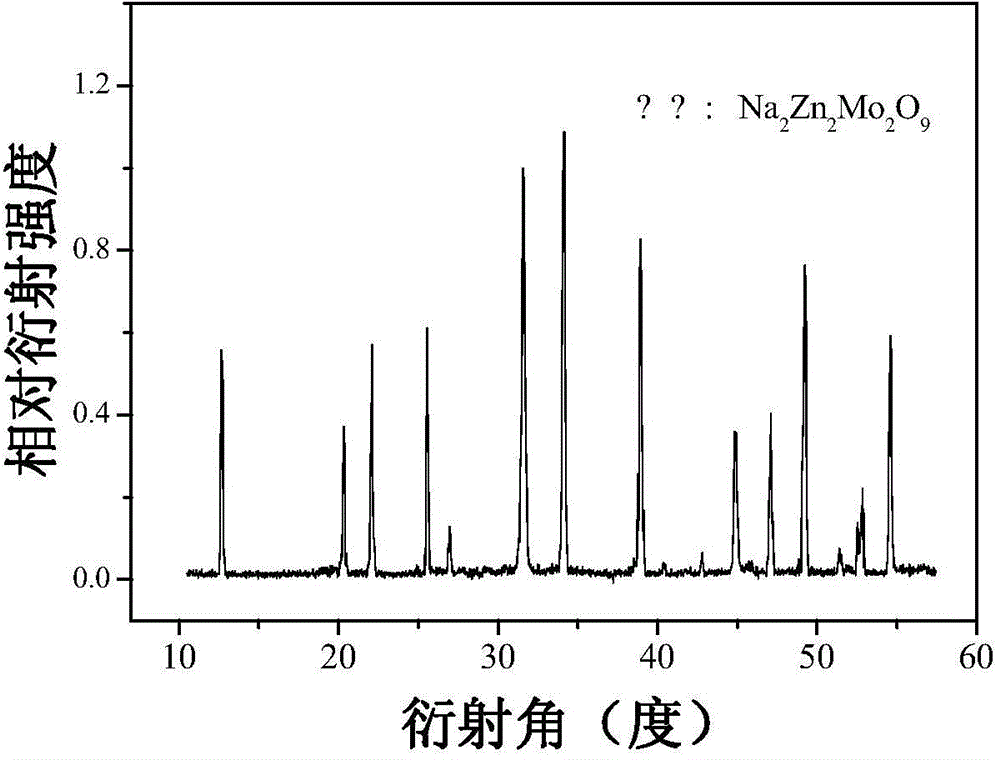

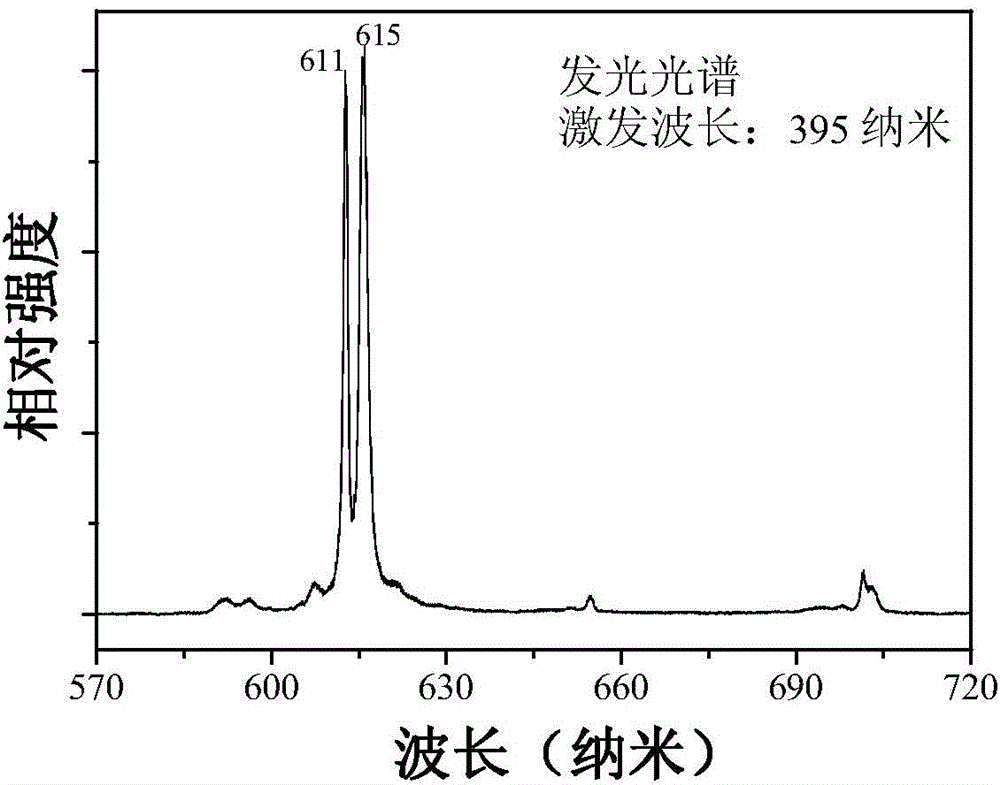

[0043] See attached Figure 6 , which is the X-ray phase diffraction spectrum of the sample prepared by the technical sc...

Embodiment 3

[0048] Preparation of NaEuZn 2 Mo 2 o 9 , according to the chemical formula NaEuZn 2 Mo 2 o 9 The stoichiometric ratio of each element in the formula is weighed separately: sodium nitrate NaNO 3 : 0.425 g, zinc nitrate Zn (NO 3 ) 2 : 2.97 g, ammonium molybdate (NH 4 ) 6 m O7 o 24 .4H 2 O: 1.766 g, europium nitrate Eu (NO 3 ) 3 : 2.22 grams, then take by weighing citric acid respectively by 0.5wt% of above each medicine quality. First dissolve the above-mentioned medicines weighed in an appropriate amount of nitric acid solution, and dilute them with 5 times its volume of deionized water. After the dissolution is complete, add the weighed citric acid to each solution, and magnetically stir for 1 hour. Until the citric acid is completely dissolved; mix the obtained solutions, continue to stir at 50°C for 2 hours, let stand and dry to obtain a fluffy precursor; place the precursor in a muffle furnace under an air atmosphere Calcination, the calcination temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com