Novel foam concrete block for self-heat-insulation of wall body and producing method of same

A technology of foam concrete and self-insulation, applied in the field of lightweight energy-saving building wall materials, can solve the problems of high damage rate, large internal stress, shear damage, etc., achieve high compressive strength, short production cycle, and improve bearing capacity and the effect of shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A new type of foam concrete block used for self-insulation of walls is prepared by the following steps:

[0029] 1) Weigh 100 parts of cement, 15 parts of fly ash, 0.6 parts of triethanolamine, 1 part of fiber, 2 parts of water reducer, and 36 parts of water, stir in a mixer and prepare a large fluid slurry.

[0030] 2) Dilute the foaming agent and water at a ratio of 1:30 and mechanically foam.

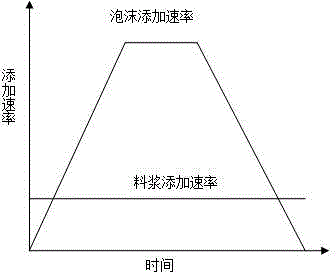

[0031] 3) Put the slurry in step 1) and the foam in step 2) into the foam mixing machine according to the set addition rate curve, mix well and continuously discharge into the mold.

[0032] 4) After curing and cutting, a foam concrete block with a length of 600mm, a width of 200mm and a height of 200mm can be obtained. The apparent density of the block is 615kg / m 3 , compressive strength ≥ 3.5 MPa, thermal conductivity ≤ 0.14 W / (m·k).

Embodiment 2

[0034] A new type of foam concrete block used for self-insulation of walls is prepared by the following steps:

[0035] 1) Weigh 100 parts of cement, 15 parts of fly ash, 0.6 parts of triethanolamine, 1 part of fiber, 2 parts of water reducer, and 36 parts of water, stir in a mixer and prepare a large fluid slurry.

[0036] 2) Dilute the foaming agent and water at a ratio of 1:30 and mechanically foam.

[0037] 3) Put the slurry in step 1) and the foam in step 2) into the foam mixing machine according to the set addition rate curve, mix well and continuously discharge into the mold.

[0038] 4) After curing and cutting, a foam concrete block with a length of 600mm, a width of 200mm and a height of 200mm can be obtained. The apparent density of the block is 820kg / m 3 , compressive strength ≥ 4.5 MPa, thermal conductivity ≤ 0.21 W / (m·k).

[0039] The slurry proportions of the above-mentioned Examples 1 and 2 are the same, and the foam addition rate curve is changed to obtain ...

Embodiment 3

[0041] A new type of foam concrete block used for self-insulation of walls is prepared by the following steps:

[0042] 1) Weigh 100 parts of cement, 20 parts of mineral powder, 1.2 parts of sodium sulfate, 2 parts of accelerator, 1 part of fiber, 0.8 parts of water reducing agent, and 65 parts of water, stir in a mixer and prepare a large fluidity slurry.

[0043] 2) Dilute the foaming agent and water at a ratio of 1:30 and mechanically foam.

[0044] 3) Put the slurry in step 1) and the foam in step 2) into the foam mixing machine according to the set addition rate curve, mix well and continuously discharge into the mold.

[0045] 4) After curing and cutting, a foam concrete block with a length of 600mm, a width of 200mm and a height of 200mm can be obtained. The apparent density of the block is 525kg / m 3 , compressive strength ≥ 2.5 MPa, thermal conductivity ≤ 0.12W / (m·k).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com