A kind of red light conversion film and its preparation method and application

A light conversion film and red phosphor technology, which is applied in the field of agricultural light conversion, can solve the problems of no light conversion effect and environmental threats, and achieve the effects of abundant reserves, avoiding environmental problems, and increasing optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The preparation method of red light conversion film can be divided into three stages: cellulose dissolution, composite process and curing film formation:

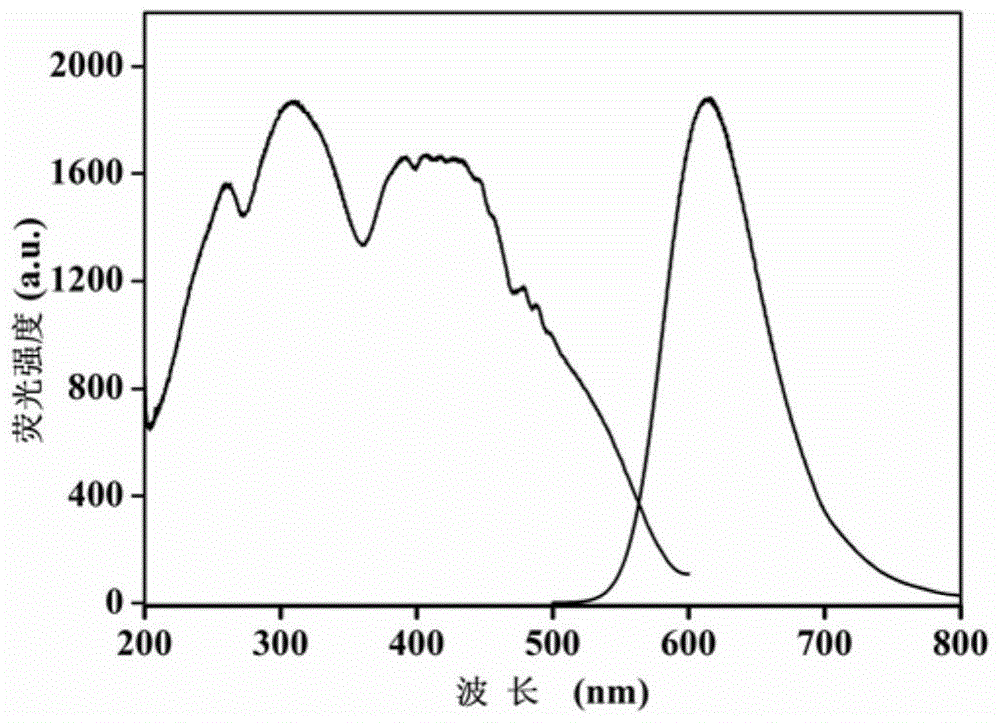

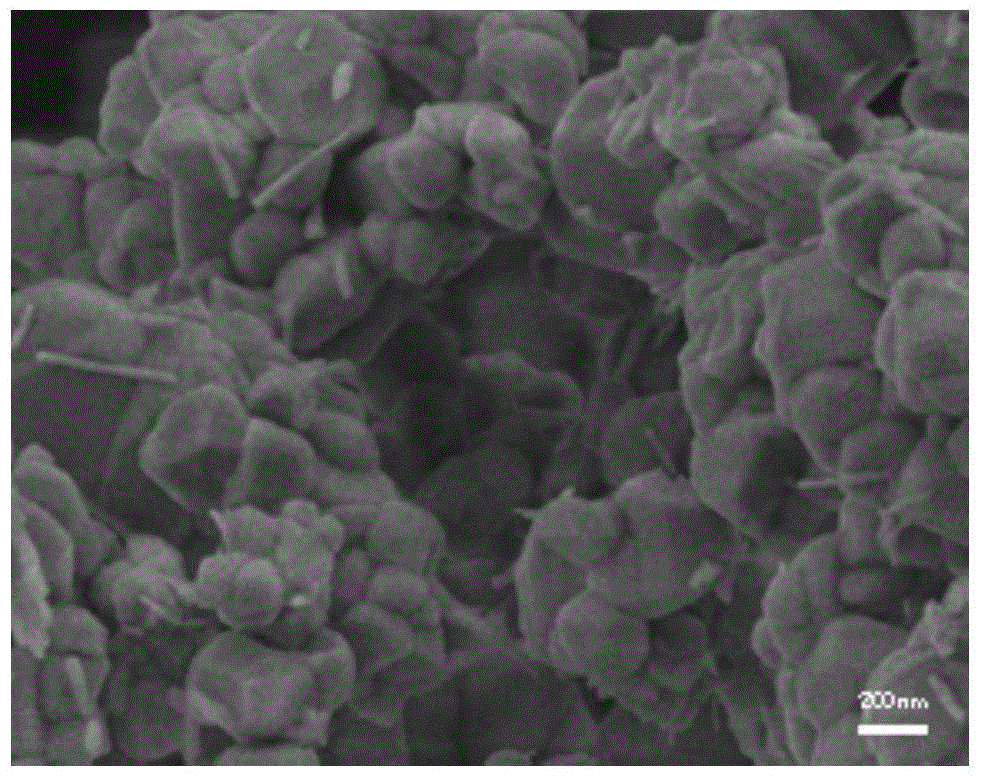

[0049] Precool 100 g of the combined aqueous solution containing 7wt% NaOH / 12wt% urea to -12°C to -13°C, add a certain amount of cotton paddle (purchased from Hubei Chemical Fiber Group Co., Ltd., DP=580), and stir rapidly to obtain 4wt% % cellulose solution. Then take 0.10g of Sr 2 Si 5 N 8 :Eu 2+ (light transfer agent Sr 2 Si 5 N 8 :Eu 2+ Excitation and emission spectra, see figure 1 ; light transfer agent Sr 2 Si 5 N 8 :Eu 2 + SEM, see figure 2 ) into the above solution, continue to stir for 30min to make it uniformly dispersed, remove air bubbles through a high-speed centrifuge to obtain a composite solution (the mass ratio of the light converting agent to cellulose in the composite solution is 1:40). After casting the composite solution on a glass plate to form a film, it was immediately immersed...

Embodiment 2

[0051] Distill 100g of 50wt% N-methylmorpholine-N-oxide aqueous solution at 85°C under reduced pressure until the water content drops to about 13.3wt%, then add 3g of cotton pulp and stir for a while to obtain a transparent , light brown cellulose / NMMO solution (wherein the final concentration of cellulose is 5.2 wt%). Then add 0.2g of Sr 2 Si 5 N 8 :Eu 2+ , and continued to stir for 30 minutes to uniformly disperse it in the cellulose mixed solution, remove air bubbles, and obtain a composite solution (the mass ratio of light-transforming agent to cellulose in the composite solution is 1:15). Cast the composite solution on a hot glass plate to form a film, let it solidify and form, wash with distilled water, spread it flat on a glass plate and dry it naturally to obtain a red light-converting film.

Embodiment 3

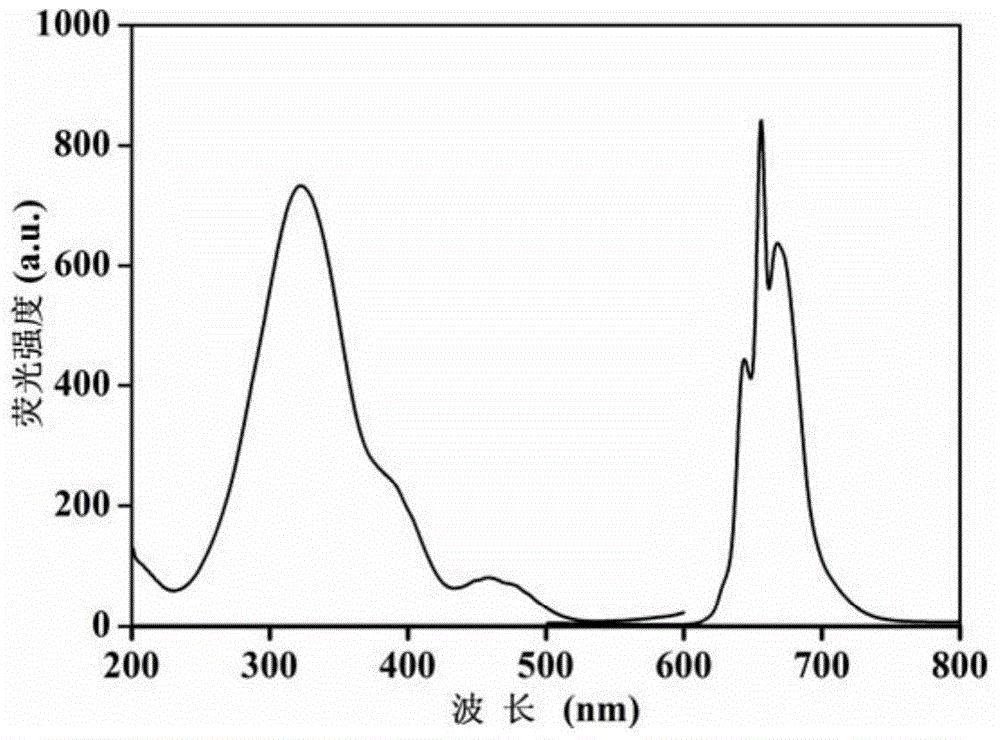

[0053] Precool 100 g of a combined aqueous solution containing 7wt% NaOH / 12wt% urea to -12°C to -13°C, add a certain amount of cotton paddle, and stir rapidly to obtain a 4wt% cellulose solution. Then add 0.20g of CaAl 12 o 19 :Mn 4+ , and continue to stir for 30 minutes to make it uniformly dispersed in the cellulose solution, remove air bubbles by a high-speed centrifuge, and obtain a composite solution (the mass ratio of light-transforming agent and cellulose in the composite solution is 1:20). After casting the composite solution on a glass plate to form a film, it was immediately immersed in 5 wt% H 2 SO 4 It was solidified and formed in the solution, and after 2 minutes, it was taken out and washed, and spread on a glass plate to dry naturally to obtain a red light-converting film. The excitation and emission spectra of the obtained light conversion film are as follows: image 3 Shown (obtained by testing with the fluorescence spectrometer F-7000 of Tianmei (China) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com