Vertical Bridgman preparation method for large-size aluminum oxide-yttrium aluminum garnet eutectic ceramic

A technology of vertical Bridgman and yttrium aluminum garnet, which is applied in the field of vertical Bridgman preparation method of large-scale alumina-yttrium aluminum garnet eutectic, which can solve the problems of small diameter of ceramic rod or plate thickness, and achieve normal temperature And the effect of outstanding high-temperature mechanical properties, easy processing, and strong thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

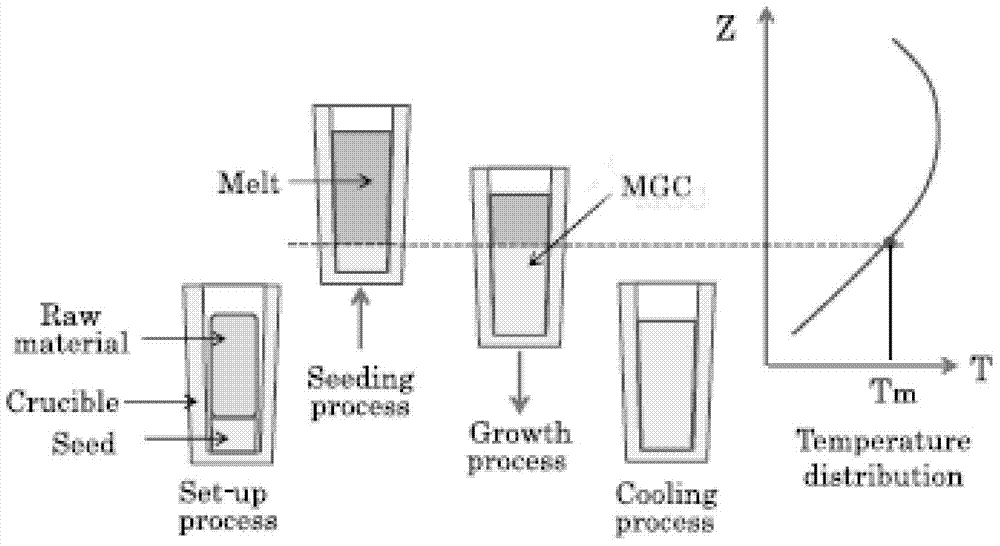

[0017] Specific embodiment one: the vertical Bridgman method (Bridgman) preparation method of a kind of large-scale alumina-yttrium aluminum garnet eutectic ceramics of the present embodiment, it comprises the following steps:

[0018] 1. Weigh 81.5mol% Al according to the mole percentage 2 o 3 and 18.5 mol% of Y 2 o 3 ;

[0019] 2. The Al taken in step 1 2 o 3 and Y 2 o 3 After being uniformly mixed by anhydrous ethanol wet ball milling, drying to remove anhydrous ethanol, and then calcining at 1273K for 15 hours, then putting it into a cylindrical plastic mold, and pressing it into a rod with a hydraulic press under the condition of 150MPa, and then The bar is sintered for 3 hours under the condition of air atmosphere and 1973K to obtain the bar body;

[0020] 3. Place the rod raw material obtained in step 2 in a molybdenum cylindrical crucible with YAG seed crystals after washing with absolute ethanol, put the molybdenum cylindrical crucible into the descending furn...

specific Embodiment approach 2

[0022] Specific embodiment two: the difference between this embodiment and specific embodiment one is: in the step 3, the relationship between the amount of bar raw material added and the inner diameter and length of the molybdenum cylindrical crucible is calculated according to the following formula: M=π*( d / 2) 2 *l*ρ; where M is the amount of raw material added, d is the inner diameter of the upper port of the molybdenum cylindrical crucible, l is the length of the molybdenum cylindrical crucible, and ρ is the density of the eutectic. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the inner diameter of the cylindrical crucible made of molybdenum does not exceed the space in the thermal field of the descending furnace. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com