In situ synthesis graphene oxide/porous ceramic composite membrane preparation method

A technology of porous ceramics and in-situ synthesis, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the difficulty of dispersion of graphene oxide membrane-making liquid, the binding force between the membrane layer and the support, and the repeated coating process Complicated and cumbersome problems, to avoid the complicated and cumbersome problems of repeated coating process, good binding force and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

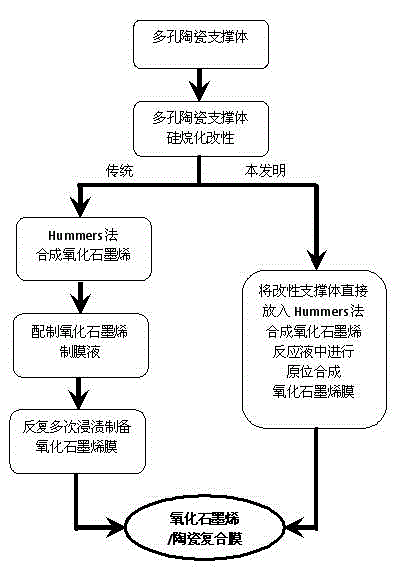

[0012] Such as image 3 Shown, the present invention is the preparation method of in-situ synthesis graphene oxide / porous ceramic composite membrane, and its steps are:

[0013] (1) Configuration of silanization modification solution: Add silane coupling agent to organic solvent to prepare silanization modification solution. The volume ratio of silane coupling agent to organic solvent is 2~5:30~50 ;

[0014] (2) Silanization modification of porous ceramic support body: Put the porous ceramic support body into the silanization modification solution, let it stand for 2-10 hours at a temperature of 30-85°C, and then take out the porous ceramic support body from the modification solution. The ceramic support body is dried at normal temperature to obtain a silane-modified porous ceramic support body;

[0015] (3) Preparation of graphene oxide / ceramic composite membrane: The silane-modified porous ceramic support was directly put into the reaction solution for preparing graphene o...

Embodiment 1

[0020] (1) Mix y-glycidyl etheroxypropyltrimethoxysilane and absolute ethanol at a volume ratio of 3:50 to prepare a silane modification solution;

[0021] (2) The flake Al with an average pore size of 350nm 2 o 3 After the support body is ultrasonicated, put it into the prepared silane modification solution, and let it stand at 70°C for 5 hours;

[0022] (3) The modified Al 2 o 3 The support body was put into the graphene oxide reaction solution prepared by the Hummers method, and the reaction time was 4 hours; (4) After the preparation was completed, the graphene oxide / porous ceramic composite membrane was taken out, washed with deionized water, and then dried at room temperature . A porous ceramic graphene oxide composite membrane prepared by in-situ oxidation was obtained. The film thickness of the graphene oxide / porous ceramic composite membrane was measured to be 80nm.

Embodiment 2

[0024] (1) Mix 3-(methacryloyloxy)propyltrimethoxysilane and toluene at a volume ratio of 3:40 to prepare a silane modification solution;

[0025] (2) Tubular Al with an average pore diameter of 80nm 2 o 3 / TiO 2 After the composite material support is polished with 1000-grit sandpaper, it is put into the prepared silane modification solution by ultrasonic, and it is left standing at 55°C for 8h;

[0026] (3) The modified Al 2 o 3 / TiO 2 The composite material support body was put into the graphene oxide reaction solution prepared by the Hummers method, and the reaction time was 4.5h;

[0027] (4) After the preparation, the graphene oxide / porous ceramic composite membrane was taken out, washed with deionized water, and left to dry at room temperature. A porous ceramic graphene oxide composite membrane prepared by in-situ oxidation was obtained. The film thickness of the graphene oxide / porous ceramic composite membrane was measured to be 120nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com