Chemical method of synthesizing Se-S-Cu (Selenium-Sulphur-Copper) ternary compound through constant temperature in-situ control

A ternary compound, in-situ synthesis technology, applied in the field of material chemistry, can solve the problems of cumbersome preparation process and unfavorable industrial production, and achieve the effects of controllable reaction process, no energy consumption, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Preparation: Cut the purchased copper sheet into 1cm×1cm copper sheet, immerse the cut copper sheet in 2M dilute hydrochloric acid, ultrasonically clean it in an ultrasonic cleaner for 10 minutes, and carry out deoxidation treatment. Rinse with deionized water for 2 to 5 times for later use; wash the beaker with tap water and distilled water in sequence, and dry it for later use;

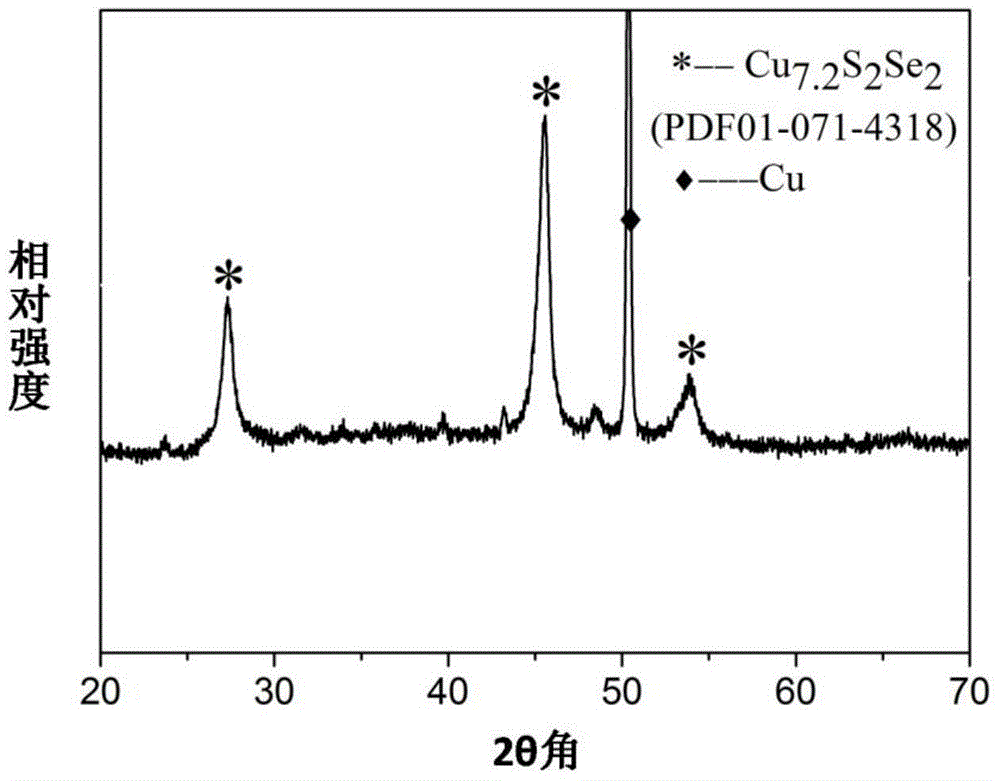

[0037] (2) Reaction step: a certain amount of elemental Se powder and Na 2 S adds a small amount of deionized water, heats in 80 DEG C blast drying oven until the selenium powder dissolves completely, and the solution turns wine red to obtain an aqueous solution with a sodium sulfide concentration of 0.0100g / ml and an elemental Se concentration of 0.0002g / ml, and then Seal the beaker with sealing glue and put it into a device with constant temperature function such as a biochemical incubator to keep the temperature at 15°C, put the deoxidized copper sheet into the reaction solution, and r...

Embodiment 2

[0040] (1) Preparation: Cut the purchased copper sheet into 1cm×1cm copper sheet, immerse the cut copper sheet in 2M dilute hydrochloric acid, ultrasonically clean it in an ultrasonic cleaner for 10 minutes, and carry out deoxidation treatment. Rinse with deionized water for 2 to 5 times for later use; wash the beaker with tap water and distilled water in sequence, and dry it for later use;

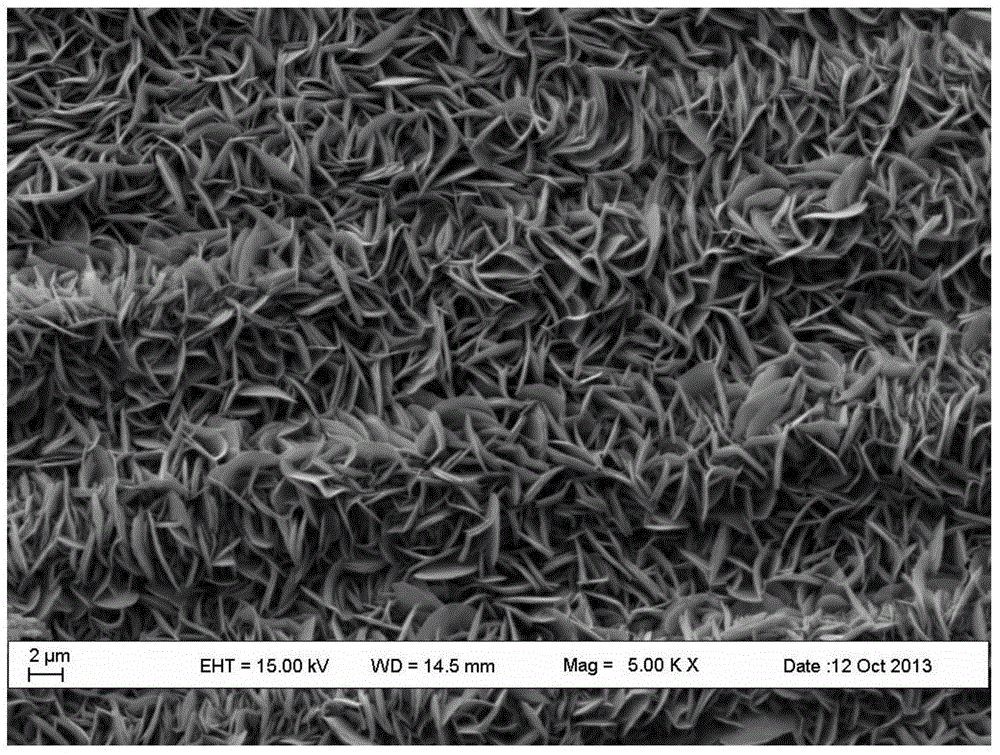

[0041] (2) Reaction step: a certain amount of elemental Se powder and Na 2 S adds a small amount of deionized water, heats until the selenium powder is completely dissolved, and the solution turns wine red to obtain an aqueous solution with a concentration of sodium sulfide of 0.0100g / ml and a concentration of elemental Se of 0.0002g / ml, then seal the beaker with a sealant and put it in A device with a constant temperature function, such as a biochemical incubator with a constant temperature of 15°C, put the deoxidized copper sheet into the reaction solution, and react at 15°C for 5 hours...

Embodiment 3

[0044] (1) Preparation: Cut the purchased copper sheet into 1cm×1cm copper sheet, immerse the cut copper sheet in 2M dilute hydrochloric acid, ultrasonically clean it in an ultrasonic cleaner for 10 minutes, and carry out deoxidation treatment. Rinse with deionized water for 2 to 5 times for later use; wash the beaker with tap water and distilled water in sequence, and dry it for later use;

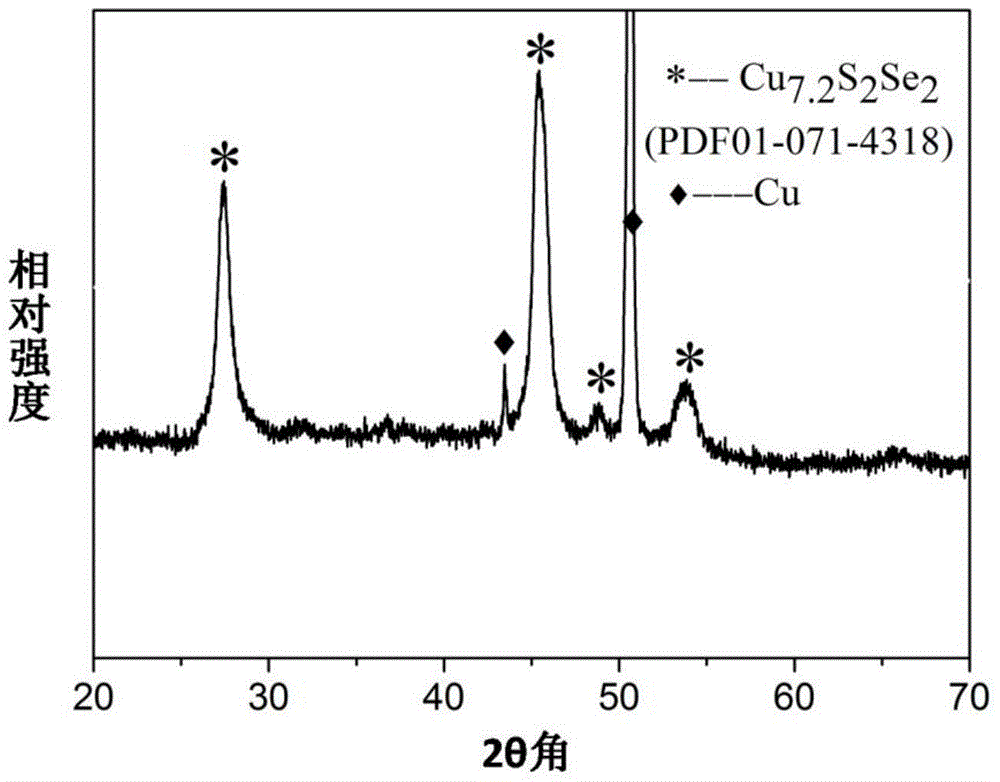

[0045] (2) Reaction step: a certain amount of elemental Se powder and Na 2 S adds a small amount of deionized water, heats until the selenium powder is completely dissolved, and the solution turns wine red to obtain an aqueous solution with a concentration of sodium sulfide of 0.0100g / ml and a concentration of elemental Se of 0.0002g / ml, then seal the beaker with a sealant and put it in A device with a constant temperature function, such as a biochemical incubator with a constant temperature of 15°C, put the deoxidized copper sheet into the reaction solution, and react at 15°C for 12 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com