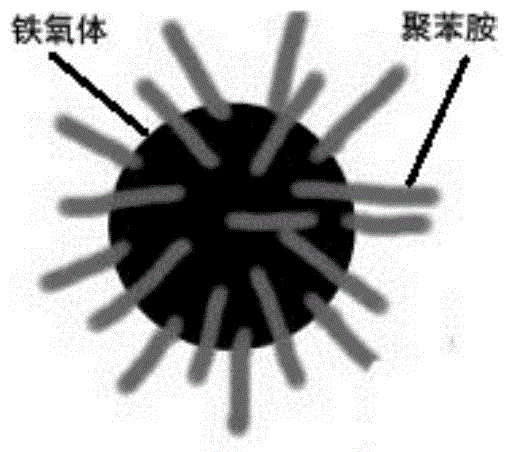

Ferrite/ polyaniline composite material and preparation method thereof

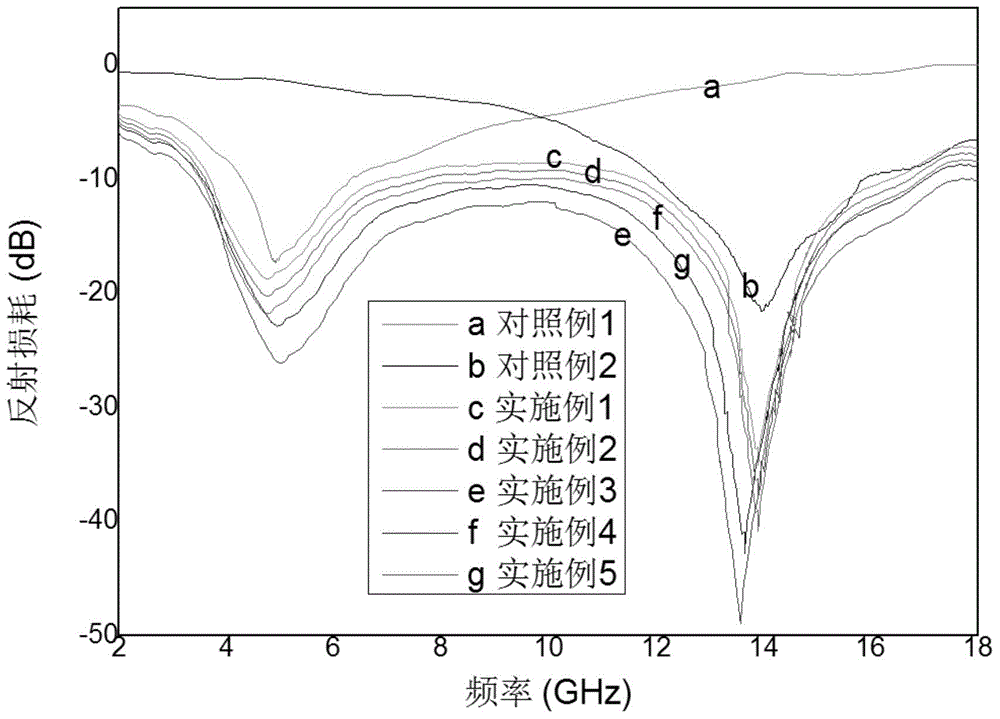

A technology of composite materials and ferrite, which is applied in the field of microwave-absorbing materials, can solve problems such as limitations, and achieve the effects of improving microwave-absorbing efficiency, broadening the absorption frequency band, and improving the absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

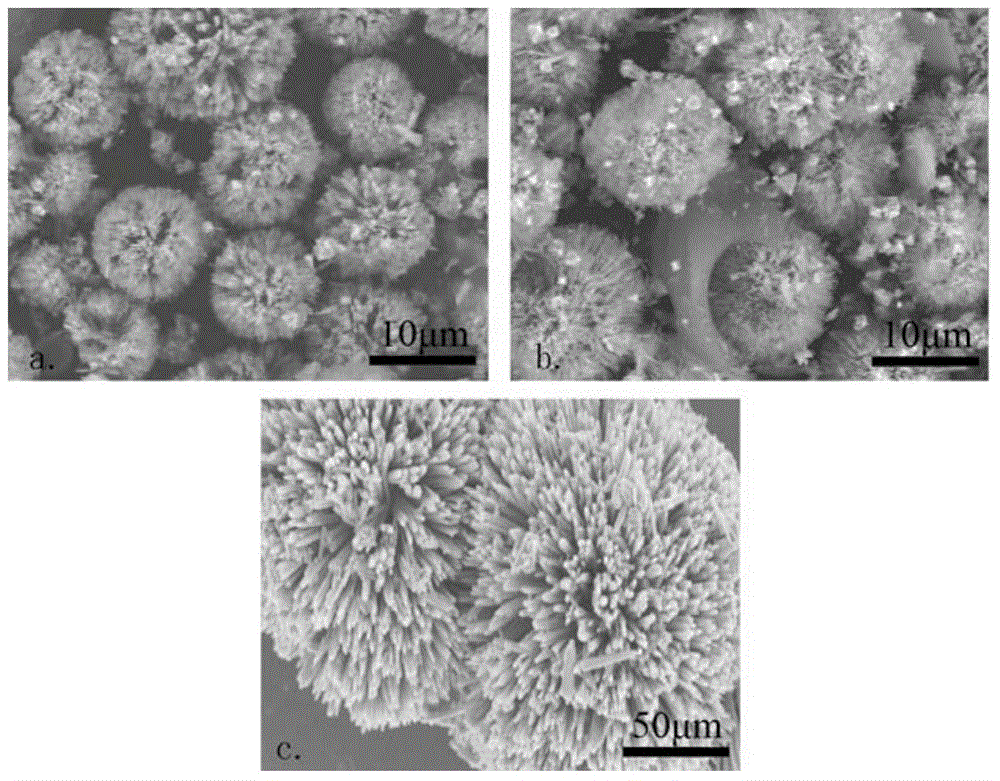

Examples

Embodiment 1

[0031] The preparation process of the ferrite / polyaniline composite material in this embodiment is (the parts are all parts by mass):

[0032] (1) Put Li-Zn ferrite (average particle size 1 μm, purchased from Aladdin Reagent) in water and fully stir it, then take it out and dry it at low temperature for later use;

[0033] (2) Dissolve 0.1 part of anilinomethyltriethoxysilane in 100 parts of absolute alcohol, stir fully for later use; put the Li-Zn ferrite treated in step (1) into the above solution, stir for 1 Take out and dry in minutes;

[0034] (3) Dissolve 0.01 part of aniline in 100 parts of carbon tetrachloride and stir evenly to form a solution; 0.01 part of ammonium persulfate, 1 part of concentrated hydrochloric acid (37%) and 1 part of Li-Zn after treatment in step (2) Add ferrite to 100 parts of water, mix well to form solution B; slowly add solution B to solution A to form an interface between organic phase and water phase, let it stand at room temperature for 0....

Embodiment 2

[0036] The preparation process of the ferrite / polyaniline composite material in this embodiment is (the parts are all parts by mass):

[0037] (1) This step is with embodiment 1;

[0038] (2) Dissolve 50 parts of anilinomethyltriethoxysilane in 100 parts of acetone, stir fully for later use; put the Li-Zn ferrite treated in step (1) into the above solution, stir for 1 minute and take out drying;

[0039] (3) Dissolve 30 parts of aniline in 100 parts of dichloromethane and stir evenly to form a solution; 10 parts of ammonium persulfate, 20 parts of concentrated hydrochloric acid (37%) and 1 part of Li-Zn iron after treatment in step (2) The oxygen body was added to 100 parts of water, and mixed evenly to form a solution B; the solution B was slowly added to the solution A to form an interface between the organic phase and the water phase, and stood at room temperature for 0.5 hours, and the product was taken out, washed and dried.

Embodiment 3

[0041] The preparation process of the ferrite / polyaniline composite material in this embodiment is (the parts are all parts by mass):

[0042] (1) This step is with embodiment 1;

[0043] (2) Dissolve 1 part of anilinomethyltriethoxysilane in 100 parts of acetone, stir fully for later use; put the Li-Zn ferrite treated in step (1) into the above solution, stir for 5 minutes and take out drying;

[0044] (3) Dissolve 5 parts of aniline in 100 parts of carbon tetrachloride and stir evenly to form a solution; 5 parts of ammonium persulfate, 5 parts of concentrated hydrochloric acid (37%) and 1 part of Li-Zn after treatment in step (2) Add ferrite to 100 parts of water, mix well to form solution B; slowly add solution B to solution A to form an interface between organic phase and water phase, let it stand at room temperature for 0.5 hours, take out the product, wash and dry it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com