Electroless copper plating method for carbon fibers

A technology of electroless copper plating and carbon fiber, which is applied in the direction of liquid chemical plating, metal material coating process, coating, etc., to achieve the effect of improving bonding ability, uniform coating, and reducing blade quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

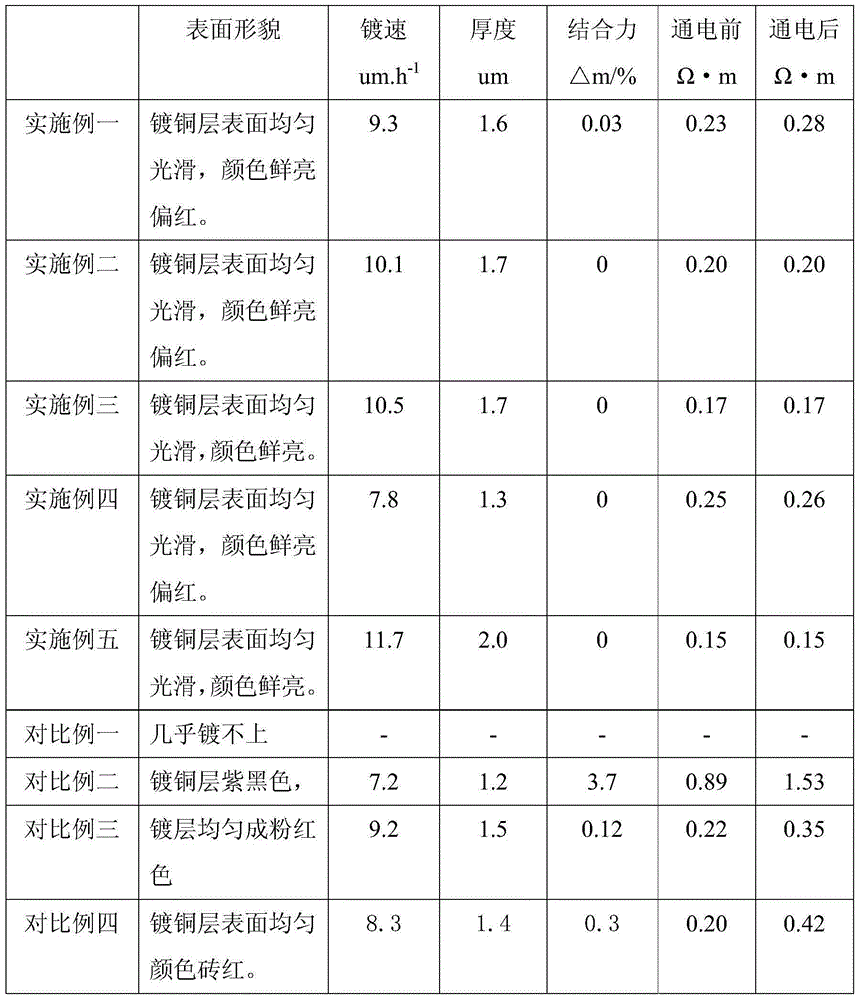

Examples

Embodiment 1

[0019] Step 1: Carbon fiber pretreatment

[0020] Surface degumming: Soak in the boiling acetone solution in the Soxhlet extractor and stir continuously with a stirring porcelain, the temperature is controlled at 70°C, and the stirring time is 240min to ensure complete acetone degumming; Surface degreasing: Put the degummed carbon fiber in 10% NaOH solution, stirred at room temperature for 30 min, the carbon fibers taken out were washed with ethanol and deionized water successively, and dried for later use.

[0021] Surface roughening: Use potassium persulfate solution with a mass fraction of 10% as the roughening solution, immerse the degreased carbon fibers at room temperature, and stir continuously for 60 minutes; use a mass fraction of 8% NaOH solution and deionized carbon fibers for the roughened carbon fibers Rinse with water until neutral, dry for later use.

[0022] Surface activation: one-step sensitization activation method, the activator is colloidal palladium solu...

Embodiment 2

[0027] Step 1: Carbon fiber pretreatment

[0028] Surface degumming: Soak in the boiling acetone solution in the Soxhlet extractor and stir continuously with a stirring porcelain, the temperature is controlled at 70°C, and the stirring time is 240min to ensure complete acetone degumming; Surface degreasing: Put the degummed carbon fiber in 10% NaOH solution, stirred at room temperature for 30 min, the carbon fibers taken out were washed with ethanol and deionized water successively, and dried for later use.

[0029] Surface roughening: Use potassium persulfate solution with a mass fraction of 10% as the roughening solution, immerse the degreased carbon fibers at room temperature, and stir continuously for 60 minutes; use a mass fraction of 8% NaOH solution and deionized carbon fibers for the roughened carbon fibers Rinse with water until neutral, dry for later use.

[0030] Surface activation: one-step sensitization activation method, the activator is colloidal palladium solu...

Embodiment 3

[0033] Step 1: Carbon fiber pretreatment

[0034] Surface degumming: Soak in the boiling acetone solution in the Soxhlet extractor and stir continuously with a stirring porcelain, the temperature is controlled at 70°C, and the stirring time is 240min to ensure complete acetone degumming; Surface degreasing: Put the degummed carbon fiber in 10% NaOH solution, stirred at room temperature for 30 min, the carbon fibers taken out were washed with ethanol and deionized water successively, and dried for later use.

[0035] Surface roughening: Use potassium persulfate solution with a mass fraction of 10% as the roughening solution, immerse the degreased carbon fibers at room temperature, and stir continuously for 60 minutes; use a mass fraction of 8% NaOH solution and deionized carbon fibers for the roughened carbon fibers Rinse with water until neutral, dry for later use.

[0036] Surface activation: one-step sensitization activation method, the activator is colloidal palladium solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com