A pt‑gfw/sio 2 /n-si heterojunction material and its preparation method

A heterojunction, pt-gfw technology, applied in the field of materials, can solve problems such as weak response to visible light, and achieve the effect of improving photovoltaic effect, superior performance and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

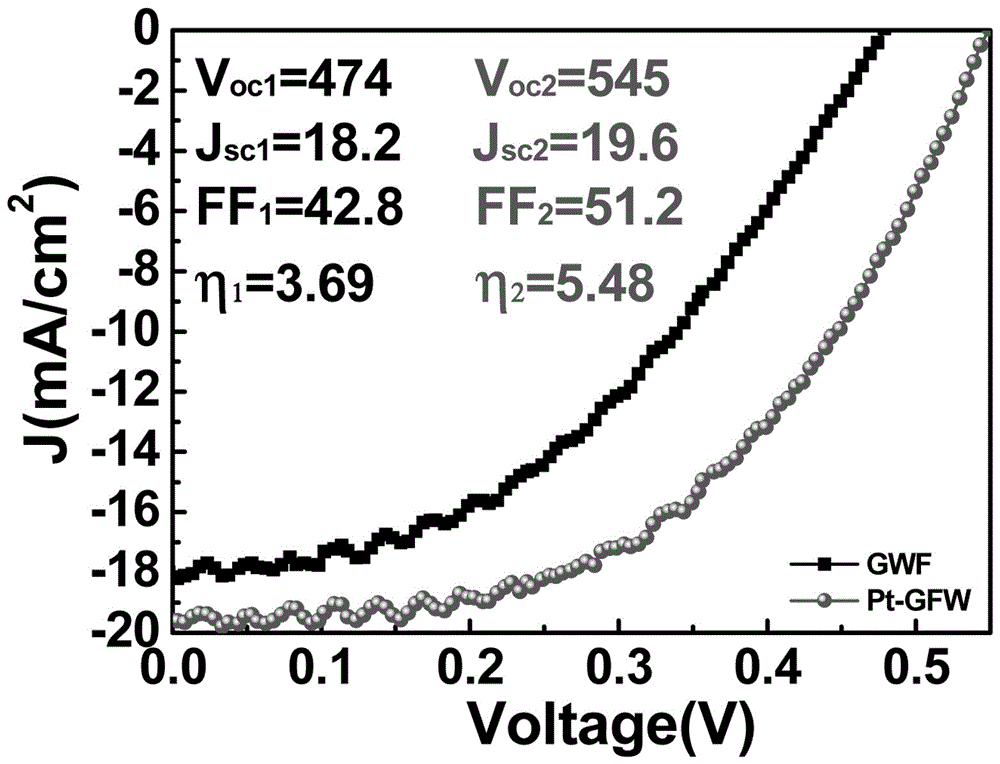

Embodiment 1

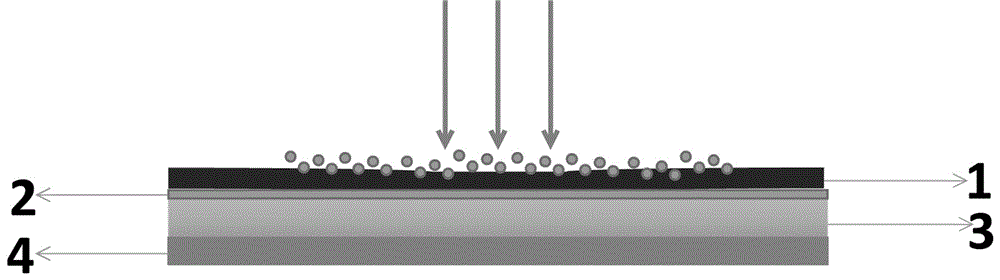

[0024] The invention improves the response of the graphene solar cell to visible light at room temperature.

[0025] First, heat the copper grid from room temperature to 1000°C in an argon atmosphere for 80 minutes, then pass hydrogen gas at 1000°C for 30 minutes, and pass argon, hydrogen, and methane at a ratio of 200:2:30 at 1000°C. , reacted for 20 minutes. Under argon protection, cool down to room temperature. The copper mesh on which the graphene mesh was grown was etched with ferric nitrate solution and washed three times with deionized water. The wafers were then ultrasonically cleaned two to three times with acetone, and then cleaned with hydrofluoric acid. The cleaned graphene mesh was then transferred to a silicon wafer. Stand still at room temperature for 15 hours to form a naturally oxidized silicon dioxide layer where the silicon of the device is not well connected to the graphene network, and thus assemble into a graphene solar cell in the usual sense.

[002...

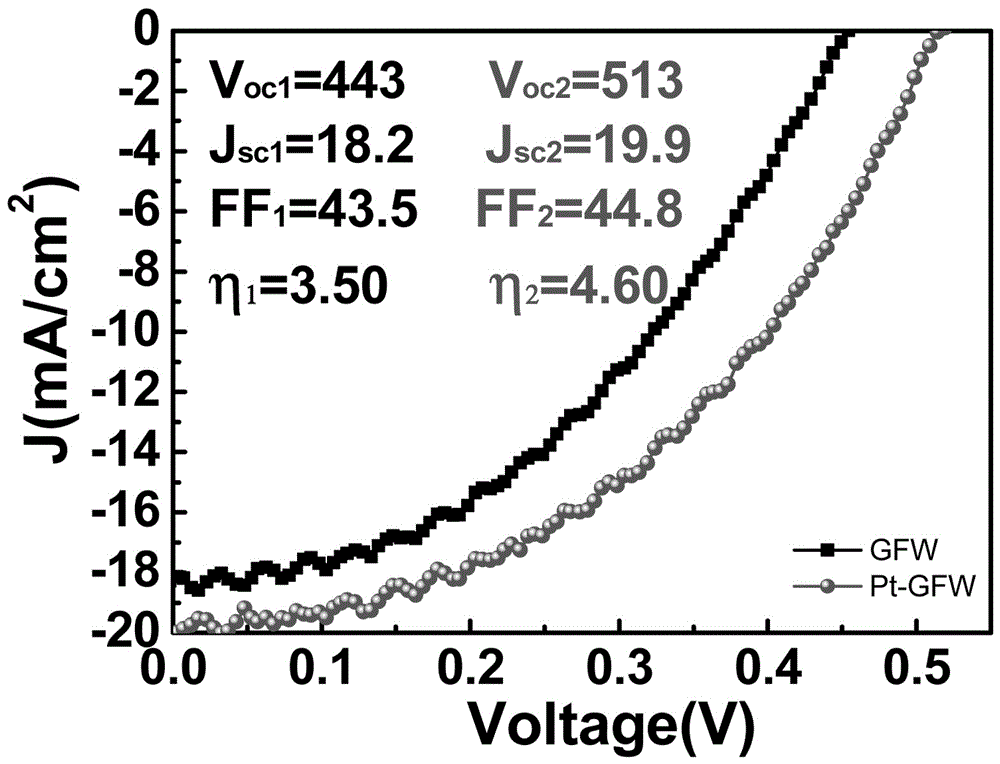

Embodiment 2

[0034] The experiment is to first heat the copper mesh from room temperature to 1000°C in an argon atmosphere for 60 minutes, then pass hydrogen gas at 1000°C for 30 minutes, and pass argon and hydrogen at a ratio of 200:2:30 at 1000°C. , methane, reacted for 20 minutes. Under argon protection, cool down to room temperature. The copper mesh on which the graphene mesh was grown was etched with ferric nitrate solution and washed three times with deionized water. The wafers were then ultrasonically cleaned two to three times with acetone, and then cleaned with hydrofluoric acid. The cleaned graphene mesh was then transferred to a silicon wafer. Stand still at room temperature for 15 hours to form a naturally oxidized silicon dioxide layer where the silicon of the device is not well connected to the graphene network, and thus assemble into a graphene solar cell in the usual sense.

[0035] The thickness of the silicon oxide layer may be 1.5-2.5 nanometers.

[0036] The thickne...

Embodiment 3

[0043] The invention improves the response of the graphene solar cell to visible light at room temperature.

[0044] First, heat the copper grid from room temperature to 1000°C in an argon atmosphere for 80 minutes, then pass hydrogen gas at 1000°C for 30 minutes, and pass argon, hydrogen, and methane at a ratio of 200:2:30 at 1000°C. , reacted for 20 minutes. Under argon protection, cool down to room temperature. The copper mesh on which the graphene mesh was grown was etched with ferric nitrate solution and washed three times with deionized water. The wafers were then ultrasonically cleaned two to three times with acetone, and then cleaned with hydrofluoric acid. The cleaned graphene mesh was then transferred to a silicon wafer. Stand still at room temperature for 15 hours to form a naturally oxidized silicon dioxide layer where the silicon of the device is not well connected to the graphene network, and thus assemble into a graphene solar cell in the usual sense.

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com