Preparation method of magnetic ferric oxide/bagasse active carbon

A technology of magnetic iron oxide and activated carbon, which is applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problems of limited arsenic adsorption effect, reduce production costs, and achieve simple and easy process. The effect of improving performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

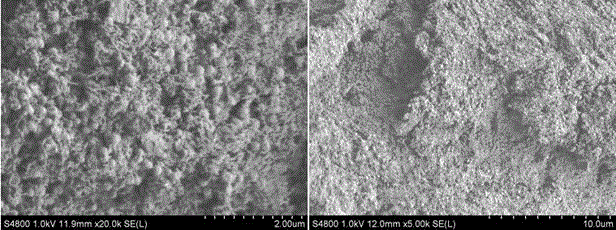

Image

Examples

Embodiment

[0016] (1) Put the bagasse that has been fully washed out of sugar in an oven at 85°C to dry, crush it with a universal crusher, and pass it through a 20-mesh standard sieve for later use.

[0017] (2) Add 1000 mL of ferrous sulfate solution with a concentration of 0.10 mol / L to a 2L wide-mouth reagent bottle with a frosted mouth, add 50 grams of bagasse obtained in step (1), stir evenly with a machine, and oscillate with ultrasonic waves for 30 minutes , let stand for 48 hours.

[0018] (3) Slowly add 10% by volume ammonia solution to the product of step (2) under mechanical stirring at a constant speed to adjust its pH value to 8.5, heat the product to 85°C with a microwave oven, and filter.

[0019] (4) Wash the filter cake obtained in step (3) with ultrapure water until the pH value of the washing solution is 7.0, then put the filter cake into a beaker containing 200 mL of analytically pure absolute ethanol, and place the beaker in an ultrasonic instrument Ultrasonic osci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com