Preparation method of caton type visible light total water splitting catalyst

A catalyst and visible light technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, oxygen preparation, etc., can solve the problems of insufficient use of solar energy and low efficiency of visible light full photolysis of water, and achieve the promotion of photogenerated electrons and holes The separation, high efficiency of total water splitting, and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

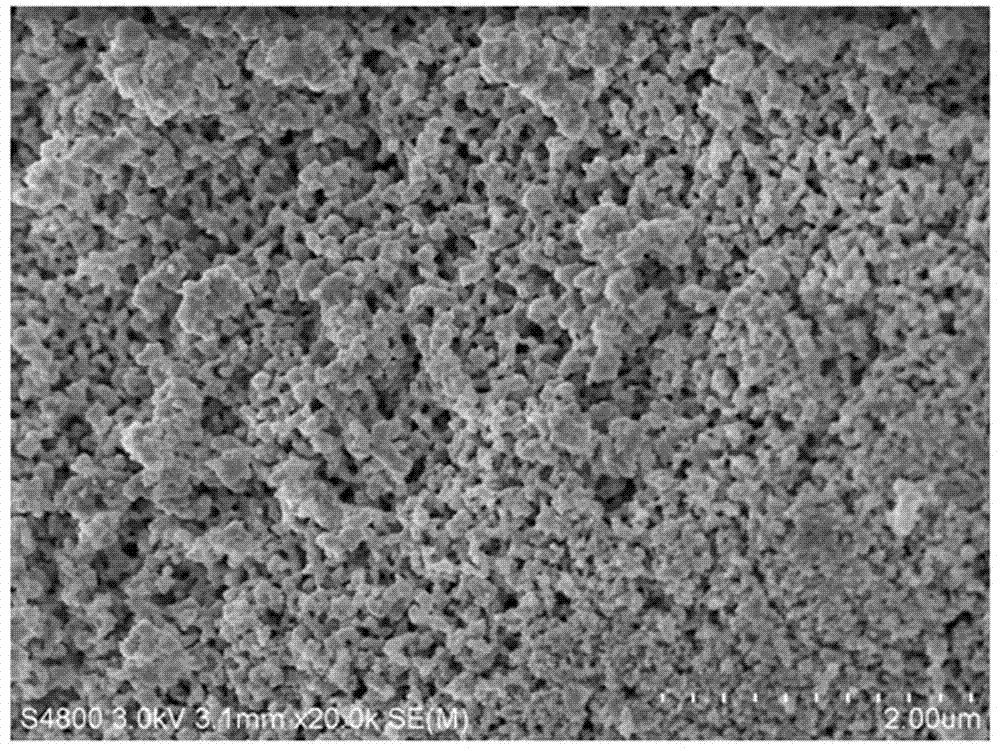

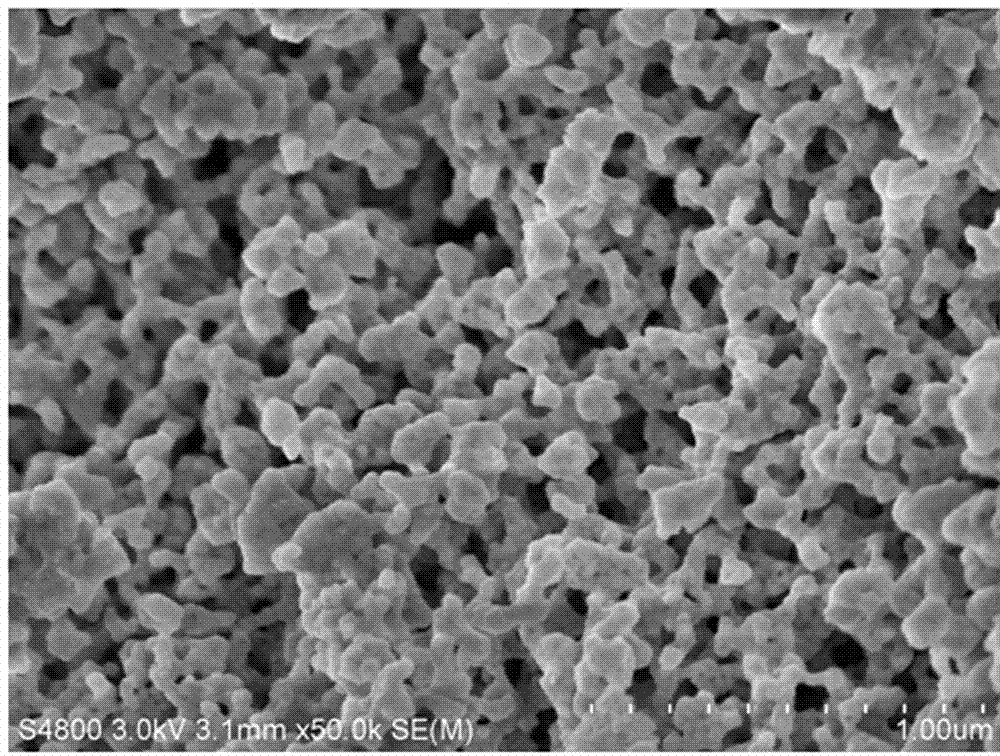

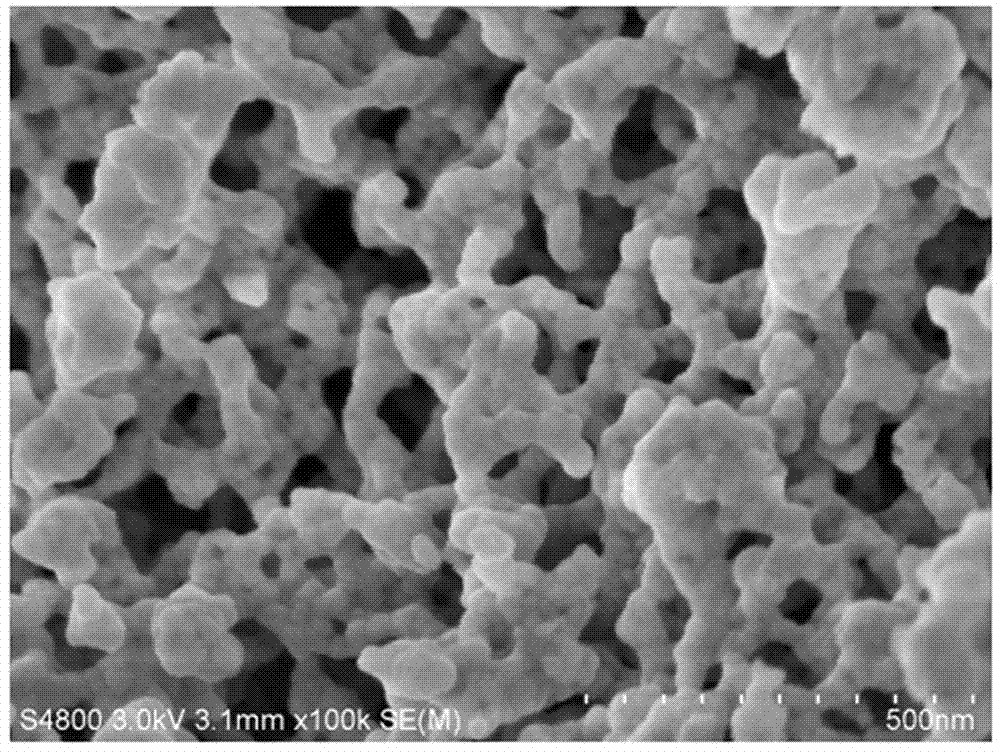

Embodiment 1

[0047] Calcium chloride, aluminum chloride, tantalum pentachloride and urea are weighed in a molar ratio of 4:1:3:200, accurately weighed and put into methanol aqueous solution (alcohol-water volume ratio 1:1) and stirred to dissolve. Put the above mixture into a large crucible and put it directly into a muffle furnace. The heating rate of the program heating is 10 ℃ / min, the high temperature setting temperature is 600 ℃, and the holding time of the high temperature stage is 12 h. After natural cooling, the obtained Precursor. The precursor is nitrided in an ammonia atmosphere, the nitriding temperature is 800°C, and the time is 24 hours. After cooling, the CATON powder is obtained. The purity of its products is not less than 99.79%, and the impurity content: carbon is less than 0.05%; chlorine is less than 0.13%. With CATON as the main catalyst, after stirring with 300 W xenon light for 24 hours (stirring speed 1000 rpm), the cocatalyst RhCrCoO was first loaded x The mixtur...

Embodiment 2

[0049] Calcium nitrate, aluminum nitrate, tantalum pentaethoxide and citric acid are in a molar ratio of 4:1:3:50, accurately weighed and put into methanol aqueous solution (alcohol-water volume ratio 1:1) and stirred to dissolve. Put the above-mentioned mixture into a large crucible and put it directly into a muffle furnace. The heating rate of the programmed temperature rise is 10 ℃ / min, the high temperature setting temperature is 800 ℃, and the holding time of the high temperature stage is 10 h. After natural cooling, the obtained Precursor. The precursor is nitrided in an ammonia atmosphere, the nitriding temperature is 850°C, and the time is 6 hours. After cooling, the CATON powder is obtained. The purity of its products is not less than 99.91%, and the impurity content: carbon is less than 0.05%; chlorine is less than 0.02%. With CATON as the main catalyst, after stirring with 300 W xenon light for 24 hours (stirring speed 1000 rpm), the cocatalyst RhCrCoO was first loa...

Embodiment 3

[0051] Calcium nitrate, aluminum nitrate, tantalum pentachloride and citric acid are in a molar ratio of 4:1:3:50, accurately weighed and put into methanol aqueous solution (alcohol-water volume ratio 1:1) and stirred to dissolve. Put the above mixture into a large crucible and put it directly into a muffle furnace. The heating rate of the programmed temperature rise is 10 ℃ / min, the high temperature setting temperature is 900 ℃, the holding time of the high temperature stage is 4 h, and after natural cooling, the obtained Precursor. The precursor is nitrided in an ammonia atmosphere, the nitriding temperature is 850°C, and the time is 7 hours. After cooling, the CATON powder is obtained. The purity of its products is not less than 99.89%, and the impurity content: carbon is less than 0.04%; chlorine is less than 0.03%. With CATON as the main catalyst, after stirring with 300 W xenon light for 24 hours (stirring speed 1000 rpm), the cocatalyst RhCrCoO was first loaded x The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com