Cholesterol derivative, O/W/O multi-phase gel emulsion prepared from cholesterol derivative, and method for preparing porous silicon dioxide bulk material from emulsion

A technology of cholesterol derivatives and gel emulsions, applied in the fields of silica, silicon oxide, organic chemistry, etc., to achieve the effect of simple method, simple preparation method and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] To synthesize cholesterol derivatives, the specific synthetic route and synthetic method are as follows:

[0049]

[0050] 1. Preparation of the compound of formula 2-1

[0051] Under nitrogen protection, add 20mL tetrahydrofuran and 14.29mL (77.5mmol) 1,8-dibromooctane to the three-necked flask, then add 3.48g (62mmol) finely ground KOH; dissolve 6g (15.5mmol) cholesterol in 30mL THF, and then add it dropwise into a three-necked flask, and react at 80°C for 48 hours. After the reaction, remove the KOH solid by filtration, remove THF by rotary evaporation, extract with dichloromethane, remove dichloromethane by rotary evaporation, and use methanol Recrystallization (3 times) to obtain white crystals, using a mixed solution of petroleum ether and methylene chloride with a volume ratio of 1:1 as a developing solvent, separated by silica gel column chromatography to obtain a compound of formula 2-1, and its structural characterization result is : 1 H-NMR (400MHz, CDCl...

Embodiment 2

[0057] Preparation of O / W / O Multiphase Gel Emulsion

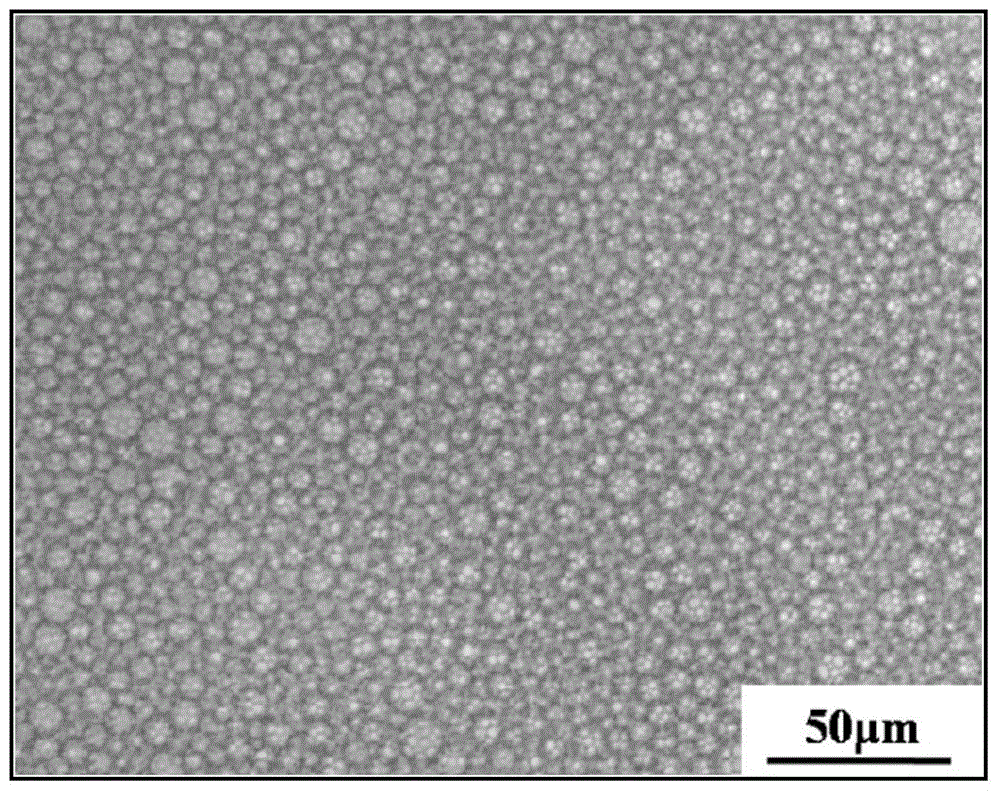

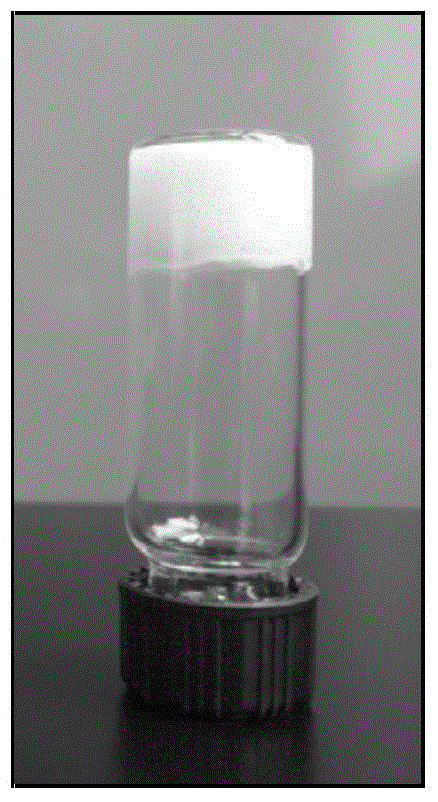

[0058] Dissolve 0.15 g of the cholesterol derivative prepared in Example 1 in 1 mL of vinyltriethoxysilane, add 4 mL of distilled water, and stir mechanically at room temperature for 2 minutes at a speed of 11400 rpm to obtain O / W / O poly Phase gel emulsion (see figure 1 and figure 2 ), it can be seen from the figure that the droplet size in the resulting heterogeneous gel emulsion is uniform, showing the characteristics of a solid.

Embodiment 3

[0060] Preparation of O / W / O Multiphase Gel Emulsion

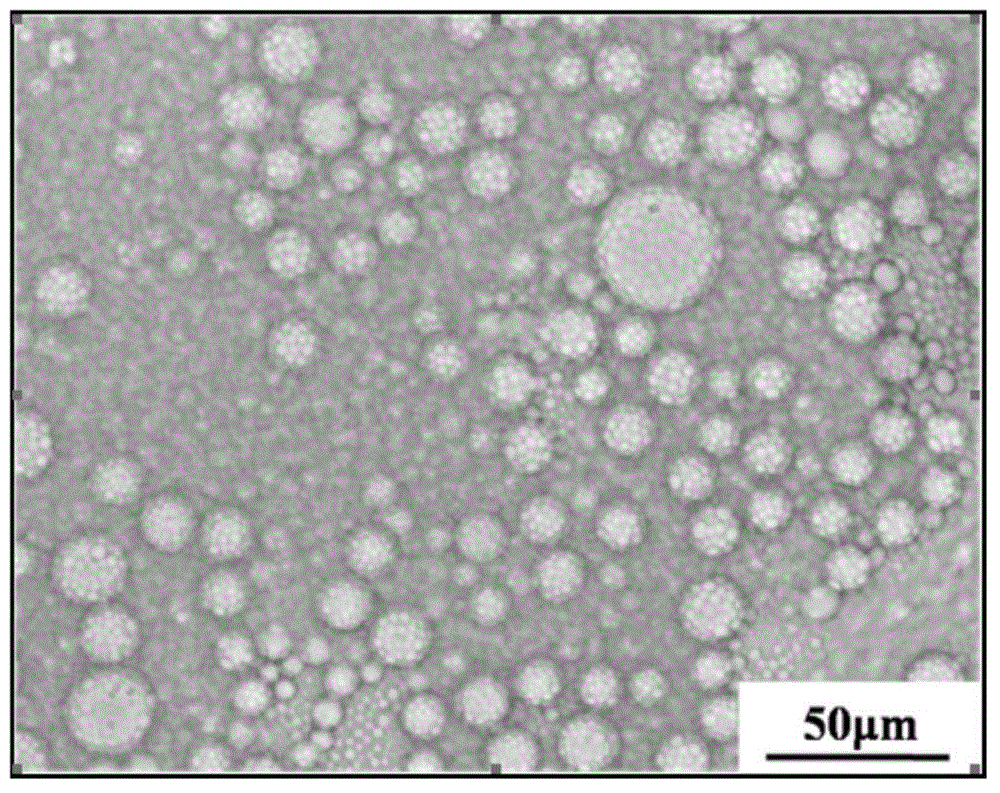

[0061] In Example 2, the vinyl triethoxysilane used was replaced with an equal volume of 3-chloropropyl triethoxysilane, and the other steps were the same as in Example 2 to obtain an O / W / O heterogeneous gel emulsion (See image 3 and Figure 4 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com