High biomass content epoxy resin composition, and curing method and applications thereof

An epoxy resin, bio-based technology, used in epoxy resin coatings, coatings, etc., can solve the problems of poor mechanical properties of cured products, low cross-linking density of cured products, and complicated processes, so as to reduce human damage and be easy to implement. , the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

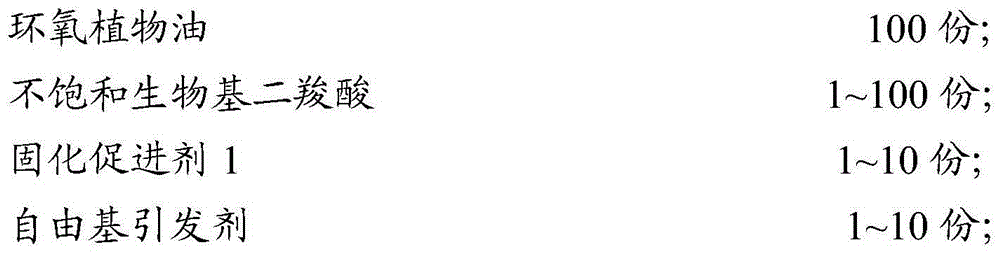

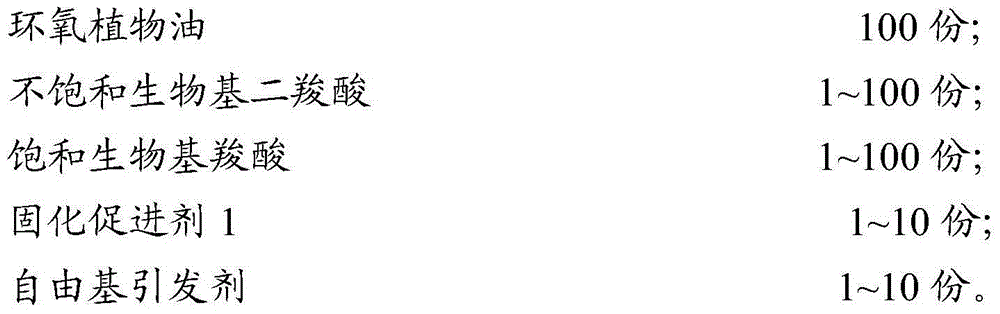

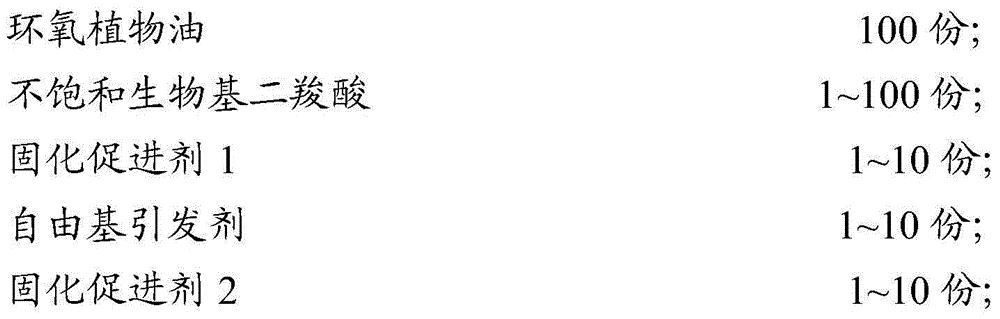

Method used

Image

Examples

Embodiment 1

[0040] 100g epoxidized soybean oil (Aladdin reagent), itaconic acid 35g (Aladdin reagent), malic acid 80g (Aladdin reagent), tetrabutylammonium bromide 1g (Sinopharm reagent), tert-butyl peroxybenzoate (Aladdin's Reagent) 10g mixed evenly, and applied on the cleaned tinplate, irradiated under 1000W high-temperature mercury lamp for 3 minutes, and cured to form a film. The glass transition temperature of this film is 85 ℃ (after the sample is solidified, grind into powder, test with the MET type differential scanning calorimeter that Mettler-Toledo company produces, N 2 atmosphere, the heating rate is 20°C / min, the same below).

Embodiment 2

[0042] With 100g epoxy castor oil (Aladdin's reagent), maleic acid 80g (Aladdin's reagent), citric acid 75g (Aladdin's reagent), triphenylphosphine 4g (National medicine reagent), tert-butyl peroxybenzoate (Aladdin's reagent) Latin reagent) 5g, mixed evenly, and applied on the cleaned tinplate, and irradiated for 3 minutes under a 1000W high-temperature mercury lamp to cure and form a film. The glass transition temperature of the film was 90°C.

Embodiment 3

[0044] 100g epoxidized soybean oil (Aladdin's reagent), itaconic acid 60g (Aladdin's reagent), triphenylphosphine 2g (National medicine reagent), tert-butyl peroxybenzoate (Aladdin's reagent) 8g, triethanolamine (National medicine Reagent) 5g, mixed evenly, and applied on the cleaned tinplate, irradiated under 1000W high-temperature mercury lamp for 3 minutes, and cured to form a film. The glass transition temperature of the film was 80°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com