MDQ phenyl hydrogen-containing silicon resin and preparing method thereof

A technology of phenyl hydrogen-containing silicon and resin, which is applied in the field of polymer materials, can solve the problems of not being able to use LED packaging, low refractive index, and inability to add curing, etc., to achieve mild production process conditions, wide sources of raw materials, and high refractive index Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

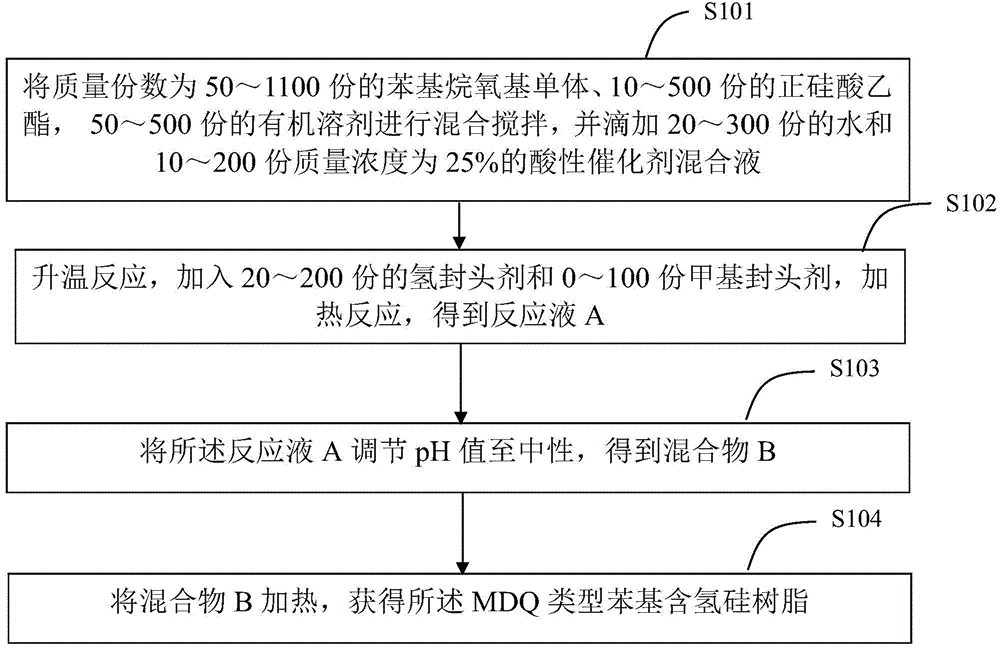

[0025] see figure 1 , The second embodiment of the present invention also provides a method for preparing the MDQ type phenyl hydrogen-containing silicone resin, which includes the following steps:

[0026] S101, mix and stir 50-1100 parts by mass of phenylalkoxy monomer, 10-500 parts of tetraethyl orthosilicate, and 50-500 parts of organic solvent, and dropwise add 20-300 parts of Water and 10-200 parts of acidic catalyst mixed solution with a mass concentration of 25%.

[0027] Specifically, 50-1000 parts by mass of diphenyldimethoxysilane monomer, 0-100 parts of dimethyldiethoxysilane monomer, 10-500 parts of ethyl orthosilicate , 50-500 parts of organic solvents are put into a three-necked flask, cooled in water bath, stirred, and 20-300 parts of water and 10-200 parts of hydrochloric acid catalyst mixed solution with a mass concentration of 25% are added dropwise thereto.

[0028] Specifically, the phenylalkoxy monomer includes at least one of diphenyldimethoxysilane an...

Embodiment 1

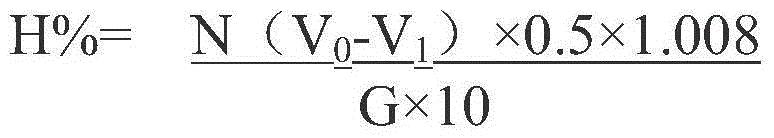

[0040] Add 256 parts of diphenyldimethoxysilane, 180 parts of ethyl orthosilicate, and 90 parts of dimethyldiethoxysilane to a 2L three-necked flask with 150 parts of methanol, and add 37 parts dropwise at 30°C. Parts of hydrochloric acid with a mass fraction of 25% and 133 parts of deionized water were fully stirred, and the dropwise addition was completed within half an hour, and then the temperature was raised to react for 5 hours, and then 76 parts of tetramethyldisiloxane capping agent was added, and the temperature was kept at 60~ 80°C, stop the reaction after 7 hours, cool to room temperature, then layered and wash with water until neutral, distill at 120°C for 3 hours under the condition of a vacuum of 0.9MPa~1.0MPa, remove low boiling point substances, and obtain colorless transparent benzene Base hydrogen-containing silicone resin 300g, viscosity 10000mPa.s / 25°C, refractive index 1.5214 / 25°C, hydrogen content 0.25% (m / m).

Embodiment 2

[0042] Add 350 parts of diphenyldimethoxysilane, 180 parts of ethyl orthosilicate, and 70 parts of dimethyldiethoxysilane to a 2L three-necked flask containing 150 parts of methanol, and add 42 parts dropwise at 30°C. Parts of hydrochloric acid with a mass fraction of 25% and 145 parts of deionized water were fully stirred, and the dropwise addition was completed within half an hour, and then the temperature was raised to react for 5 hours, and then 85 parts of tetramethyldisiloxane capping agent was added, and the temperature was kept at 60~ 80°C, stop the reaction after 7 hours, cool to room temperature, then layered and wash with water until neutral, distill at 120°C for 3 hours under the condition of a vacuum of 0.9MPa~1.0MPa, remove low boiling point substances, and obtain colorless transparent benzene Based on 350g of hydrogen-containing silicone resin, the viscosity is 30000mPa.s / 25°C, the refractive index is 1.52 / 25°C, and the hydrogen content is 0.24% (m / m).

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com