Environment-friendly three-proofing lacquer

A three-proof paint, environmentally friendly technology, used in coatings, reagents, educts and other directions, can solve the problems of mildew, circuit board failure, corrosion, etc., to achieve reasonable ratio, prevent leakage, and improve insulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

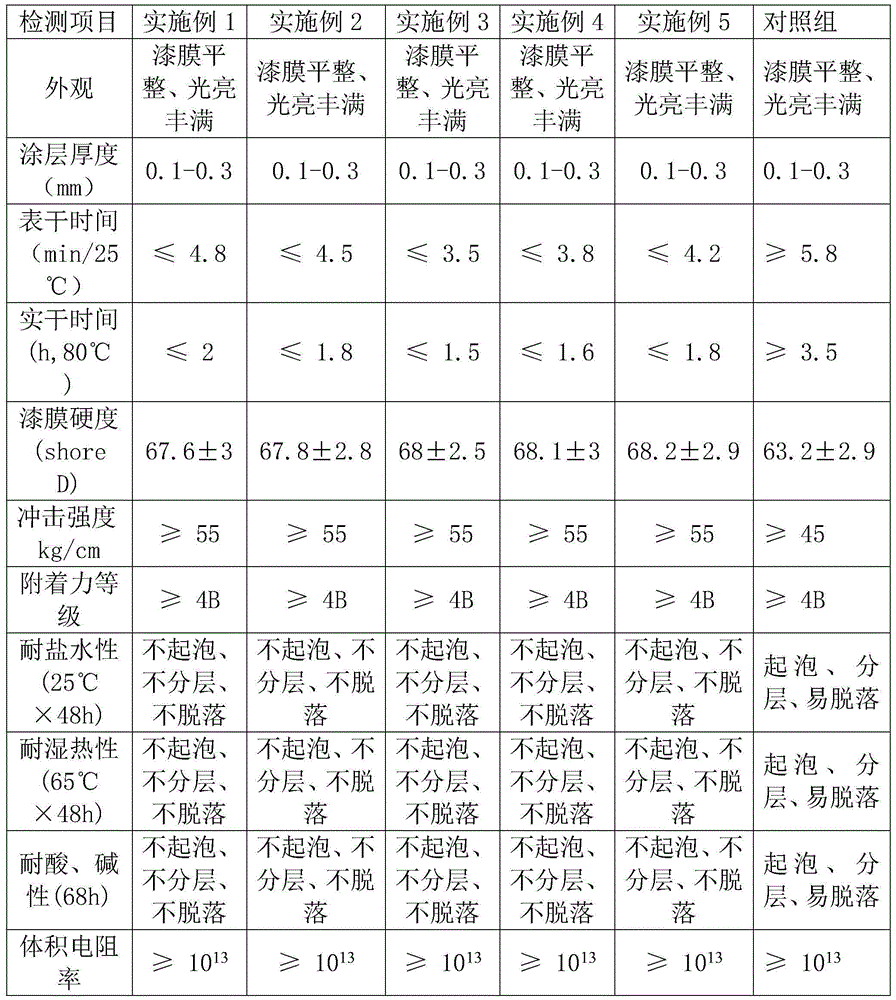

Examples

Embodiment 1

[0019] An environment-friendly conformal paint, the mass parts of the environment-friendly conformal paint are composed as follows: 18 parts of acrylic resin, 8 parts of triethylenetetramine, 40 parts of isopropanol, 10 parts of ethyl acetate, titanate coupling 1 part of agent, 6 parts of butyl acetate, 10 parts of rosin modified alkyd resin, 1 part of defoamer, 2 parts of waterproof additive, and 1 part of antistatic additive.

[0020] The composition of the defoamer in parts by mass is as follows: 20 parts of white oil, 20 parts of naphthenic oil, 2 parts of white carbon black, 2 parts of aluminum oxide, 1.2 parts of polyamide wax and modified polyamide wax, fatty acid polyoxyethylene ether 0.8 servings.

[0021] Described white carbon black selects gas-phase process hydrophobic white carbon black for use, and its specific surface area is 50m 2 / g.

[0022] The waterproofing additive is selected from nano-osmotic waterproofing agent.

[0023] The antistatic additive is a ...

Embodiment 2

[0025] An environment-friendly three-proof paint, the composition of the environment-friendly three-proof paint is as follows: 20 parts of acrylic resin, 10 parts of triethylenetetramine, 42 parts of isopropanol, 12 parts of ethyl acetate, titanate coupling agent 2 parts, 8 parts of butyl acetate, 12 parts of rosin modified alkyd resin, 2 parts of defoamer, 3 parts of waterproof additive, 2 parts of antistatic additive.

[0026] The composition of the defoamer in parts by mass is as follows: 24 parts of white oil, 24 parts of naphthenic oil, 3 parts of white carbon black, 3 parts of aluminum oxide, 1.5 parts of polyamide wax and modified polyamide wax, fatty acid polyoxyethylene ether 1.2 servings.

[0027] Described white carbon black selects gas-phase process hydrophobic white carbon black for use, and its specific surface area is 60m 2 / g.

[0028] The waterproofing additive is selected from nano-osmotic waterproofing agent.

[0029] The antistatic additive is a mixture ...

Embodiment 3

[0031] An environment-friendly three anti-paint, the mass parts of the environment-friendly three anti-paint are composed as follows: the mass parts of the environment-friendly three anti-paint are composed as follows: 20 parts of acrylic resin, 10 parts of triethylenetetramine, 45 parts of isopropanol 12 parts of ethyl acetate, 2 parts of titanate coupling agent, 9 parts of butyl acetate, 15 parts of rosin modified alkyd resin, 3 parts of defoamer, 4 parts of waterproof additive, 2 parts of antistatic additive.

[0032] The composition of the defoamer in parts by mass is as follows: 30 parts of white oil, 25 parts of naphthenic oil, 5 parts of white carbon black, 4 parts of aluminum oxide, 1.8 parts of polyamide wax and modified polyamide wax, fatty acid polyoxyethylene ether 1.2 servings.

[0033] Described white carbon black selects gas-phase process hydrophobic white carbon black for use, and its specific surface area is 90m 2 / g.

[0034] The waterproofing additive is s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com