Fluorine-containing high dielectric polynorbornene-poly(1,6-heptadiyne) block copolymer and preparation method thereof

A technology of polynorbornene and block copolymer, which is applied in the field of high dielectric polymer preparation, can solve the problem that the related work of dielectric materials has not yet been reported, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Example 1: Synthesis of N-3,5-difluorophenyl norbornenepyrrolidine

[0060] At room temperature, dissolve 3,6-endomethine-1,2,3,6-tetrahydrophthalic anhydride (9.84g, 60mmol) and 3,5-difluoroaniline (6.45g, 50mmol) in 50mL In anhydrous 1,2-dichloroethane. Nitrogen gas was introduced, and 0.3 equivalent of DMAP (1.83 g, 15 mmol) was added to the reaction solution. Reflux at 90°C for 36 hours, and the reaction is complete. After washing, drying, and solvent removal for many times, the crude product is recrystallized to obtain white crystals, which is a norborneneimide compound containing 3,5-difluorophenyl. Under an ice bath, nitrogen was introduced into the reaction flask, lithium aluminum hydride (4.56 g, 120 mmol) was quickly added into the flask, and 100 mL of anhydrous ether was injected to obtain a suspension of lithium aluminum hydride. Subsequently, the norbornenimide compound (6.7 g, 24 mmol) containing 3,5-difluorophenyl was dissolved in 80 mL of dry dichloromet...

Embodiment 2

[0062] Example 2: Synthesis of pentafluorophenyl 4-carboxylate-1,6-heptadiyne

[0063] At room temperature, add 4-carboxy-1.6-heptadiyne (3.2g, 20mmol), pentafluorophenol (2.2g, 24mmol), DMAP (0.5g, 4mmol) and 60mL dichloromethane into a three-necked flask, stir to dissolve EDCI (4.6g, 24mmol) was added to the system, and stirring continued for 36h, the system changed from turbidity to clear. After detecting the completion of the reaction by thin-layer chromatography, it was washed successively with distilled water (30×6 mL) and saturated brine (30×3 mL), dried over anhydrous sodium sulfate, and the solvent was removed by rotary evaporation to obtain a light yellow solid. Recrystallization was performed with a mixed solvent of ethyl acetate and petroleum ether to obtain 4.3 g of white crystals (yield: 64%).

[0064] M.p.48.5-49.4℃. 1 H NMR(500MHz, CDCl 3 , ppm): δ3.18 (m, 1H, OCOCH), 2.83-2.81 (m, 4H, CHCCH 2 ), 2.14(t,2H,CHCCH 2 ); 13 C NMR(CDCl 3 ):δ(ppm)168.51(CHCOO), 142.04-13...

Embodiment 3

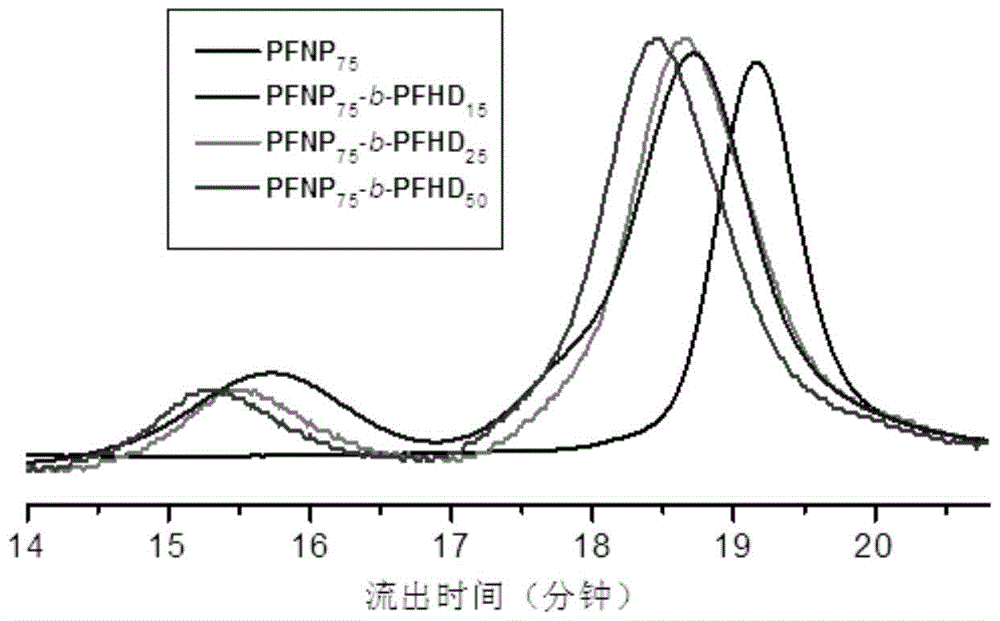

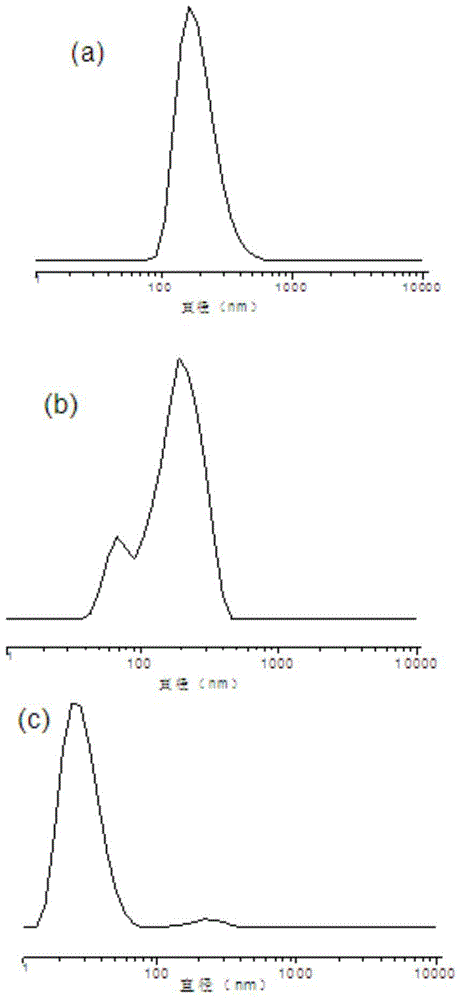

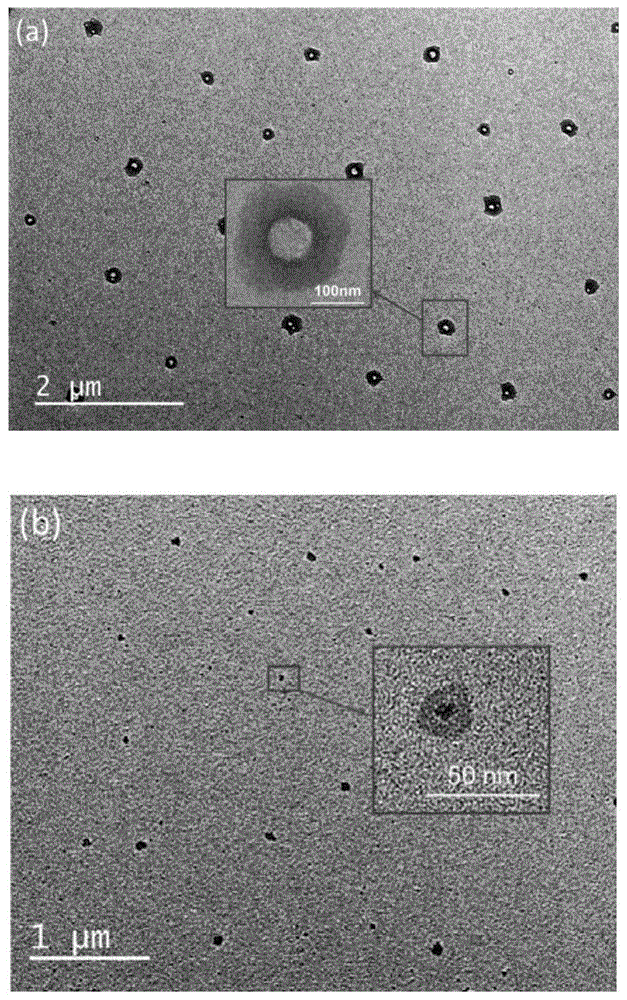

[0065] Example 3: Preparation of polynorbornene-poly(1,6-heptadiyne) block copolymers with different block ratios

[0066] In a 25mL Schlenk reaction tube, add N-3,5-difluorophenylnorbornenepyrrolidine (185.2mg, 0.75mmol), vacuum and replace with high-purity nitrogen 3 times, add 2.7mL tetrahydrofuran to make it completely dissolved. Add pentafluorophenyl 4-formate-1,6-heptadiyne (45.2mg, 0.15mmol) to another 25mL Schlenk reaction tube, vacuum and replace with high-purity nitrogen 3 times, add 0.3mL tetrahydrofuran to make it completely dissolved. Under a nitrogen atmosphere, weigh the Grubbs third-generation catalyst (8.8mg, 0.01mmol) in the third Schlenk tube, evacuate and replace with nitrogen three times, and then add 1mL of tetrahydrofuran. The reaction system was frozen by liquid nitrogen, evacuated and filled with nitrogen. After repeating the cycle 3 times, it was thawed; after preheating at 30°C for 10 minutes, the catalyst solution was quickly added to the N-3,5-diflu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com