Erbium-doped lanthanum titanate fluorescent compound and its preparation method and application

A fluorescent compound, lanthanum titanate technology, applied in the field of fluorescent compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

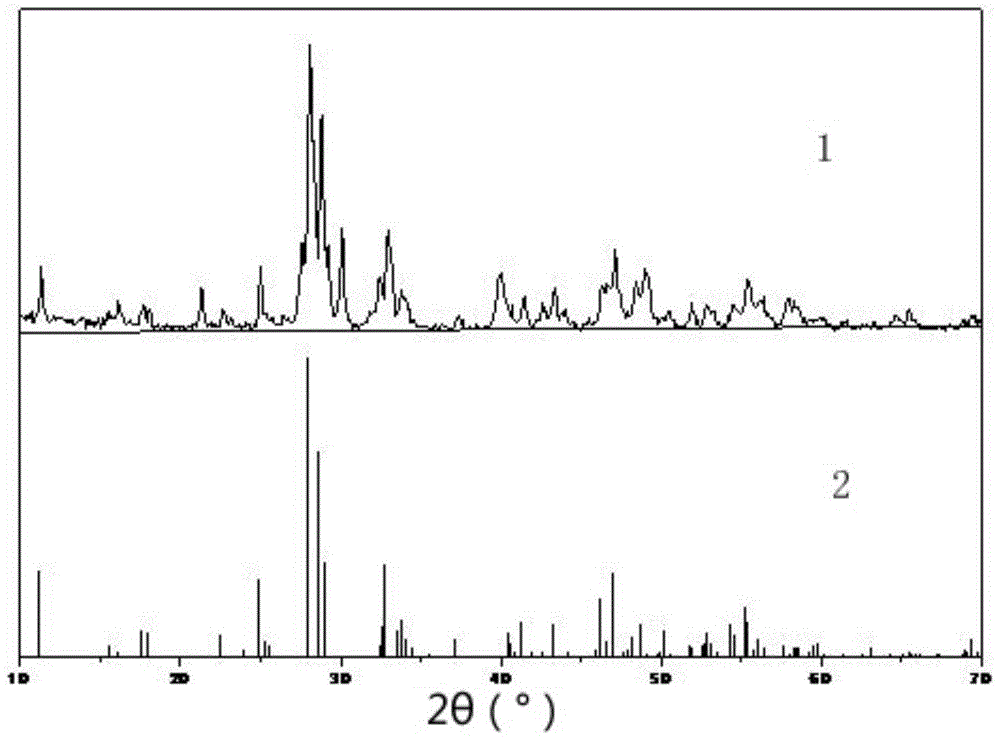

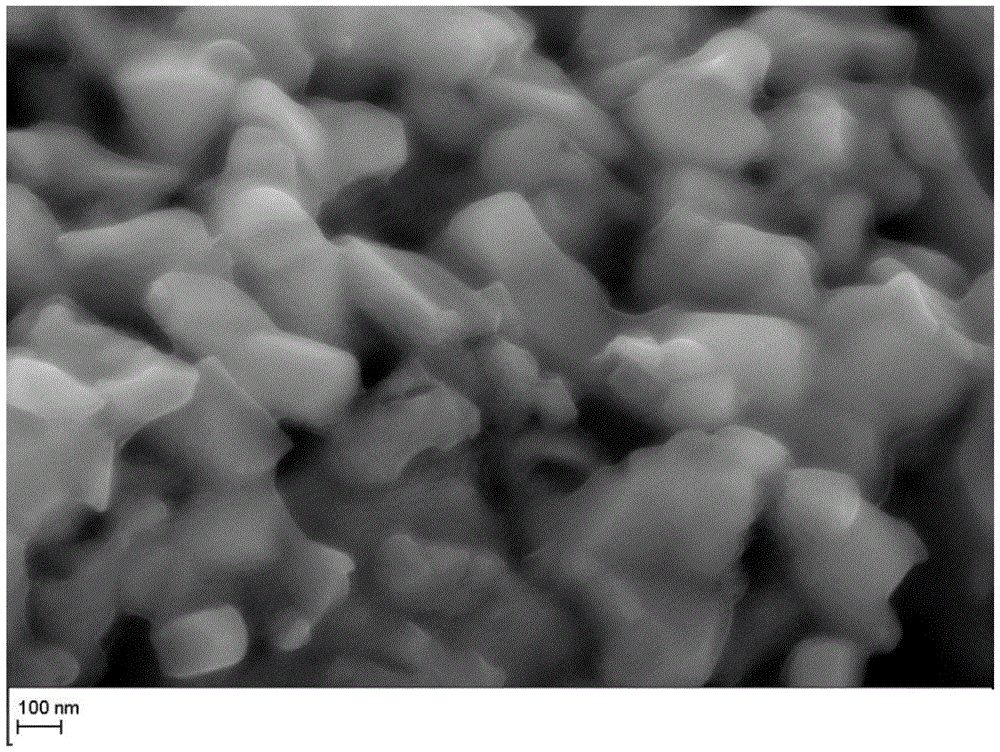

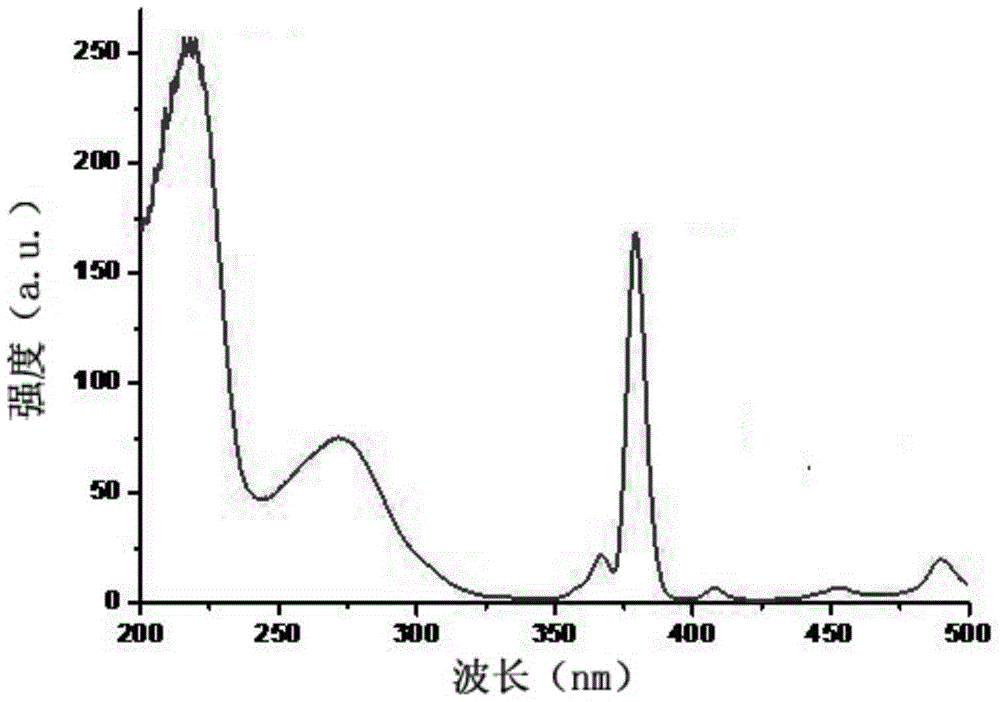

[0054] A fluorescent compound of erbium-doped lanthanum titanate with the chemical formula La 1.99 Er 0.01 TiO 5 , made by the following steps:

[0055] (1) Weigh 1.99mmol La soluble salt and 0.01mmol Er soluble salt and dissolve them in deionized water to obtain solution A; dissolve 1mmol tetrabutyl titanate in 50mL methanol to obtain solution B; wherein, La soluble salt is nitric acid Salt, the soluble salt of Er is acetate;

[0056] (2) Mix solution A and solution B, add 10 mmol of nitric acid dropwise while stirring, and stir for 1.5 hours to obtain a clear solution C, raise the temperature of solution C to 60° C., and keep it warm in a water bath for 6 hours to obtain a precursor gel;

[0057] (3) Put the precursor gel in a corundum crucible and calcinate in a muffle furnace. The calcining temperature is 1100°C in an air atmosphere, the calcining time is 4 hours, and the holding time is 1 hour. Cool to room temperature with the furnace to obtain a calcined product ; ...

Embodiment 2

[0060] A fluorescent compound of erbium-doped lanthanum titanate with the chemical formula La 1.98 Er 0.02 TiO 5 , made by the following steps:

[0061] (1) Weigh 1.98mmol La soluble salt and 0.02mmol Er soluble salt and dissolve them in deionized water to obtain solution A; dissolve 1mmol tetrabutyl titanate in 100mL ethanol to obtain solution B; wherein, La soluble salt is vinegar Salt, the soluble salt of Er is carbonate;

[0062] (2) Mix solution A and solution B, add 30 mmol of carbonic acid dropwise while stirring, and stir for 1 hour to obtain a clear solution C, raise the temperature of solution C to 80° C., and keep it warm in a water bath for 3 hours to obtain a precursor gel;

[0063] (3) Put the precursor gel in a corundum crucible and calcinate in a muffle furnace. The calcining temperature is 1000°C in an air atmosphere, the calcining time is 3 hours, and the holding time is 4 hours. Cool to room temperature with the furnace to obtain a calcined product ;

...

Embodiment 3

[0066] A fluorescent compound of erbium-doped lanthanum titanate with the chemical formula La 1.92 Er 0.08 TiO 5 , made by the following steps:

[0067] (1) Dissolve 3.84mmol La soluble salt and 0.16mmol Er soluble salt in deionized water to obtain solution A; dissolve 2mmol tetrabutyl titanate in 100mL propanol to obtain solution B; wherein, the soluble salt of La is Carbonate, the soluble salt of Er is nitrate;

[0068] (2) Mix solution A and solution B, add 50 mmol of acetic acid dropwise while stirring, and stir for 5 hours to obtain a clear solution C, then raise the temperature of solution C to 70°C, keep it in a water bath for 6 hours, and obtain a precursor gel;

[0069] (3) Put the precursor gel in a corundum crucible and calcinate in a muffle furnace. The calcining temperature is 900°C in an air atmosphere, the calcining time is 6 hours, and the holding time is 1 hour. Cool to room temperature with the furnace to obtain a calcined product ;

[0070] (4) The calc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com