Bottom anti-reflection coating composition based on molecule glass comprising multiple hydroxy structures and application thereof to photoetching

A bottom anti-reflection, molecular glass technology, used in photosensitive materials, optics, and optomechanical equipment for optomechanical equipment, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] 1) Preparation of BARC material 1

[0084] 60mg (9.082×10 -5 mol) 2,2-bis(4-hydroxy-3,5-bis(3,4-dihydroxyphenyl)phenyl)propane (molecular weight 660.67g / mol) molecular glass compound (as shown in formula V below), 6mg PAG (N-hydroxynaphthalimide trifluoromethanesulfonic acid) (accounting for 10% of molecular glass compound quality), 6mg light absorber anthracene (accounting for 10% of molecular glass compound quality) three are mixed in test tube after weighing, Then add 0.3mL of 4mg / mL anti-acid diffusing agent trioctylamine (TOA) made with PGMEA solvent (TOA accounts for 2% of the mass of the acid generator), mix the above substances, add 0.7mL of PGMEA solvent, and stir ultrasonically for 1 hour Mix the above to form component a, and pipette 0.371mL (1.816×10 -3 mol, and the molecular glass compound molar ratio is 1:20) triethylene glycol divinyl ether (abbreviated as DVE-3, as shown in the following formula VI, molecular weight 202.25g / mol, density 0.99g / mL), diss...

Embodiment 2

[0096] The steps are basically the same as in Example 1, the only difference is that the photoresist for spin coating is 365 photoresist specially provided by Beijing Kehua Microelectronics Company for 365 exposure.

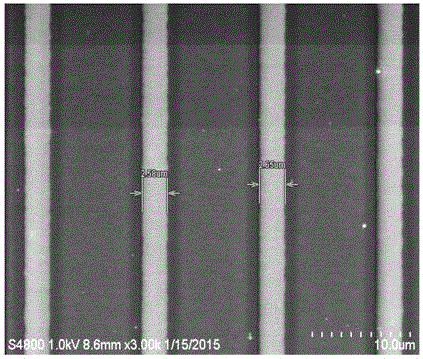

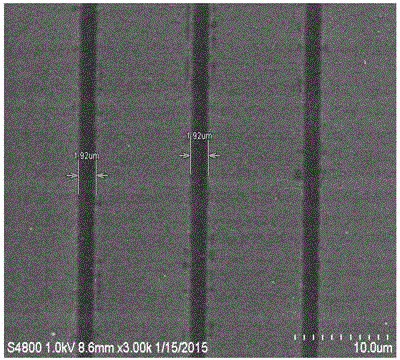

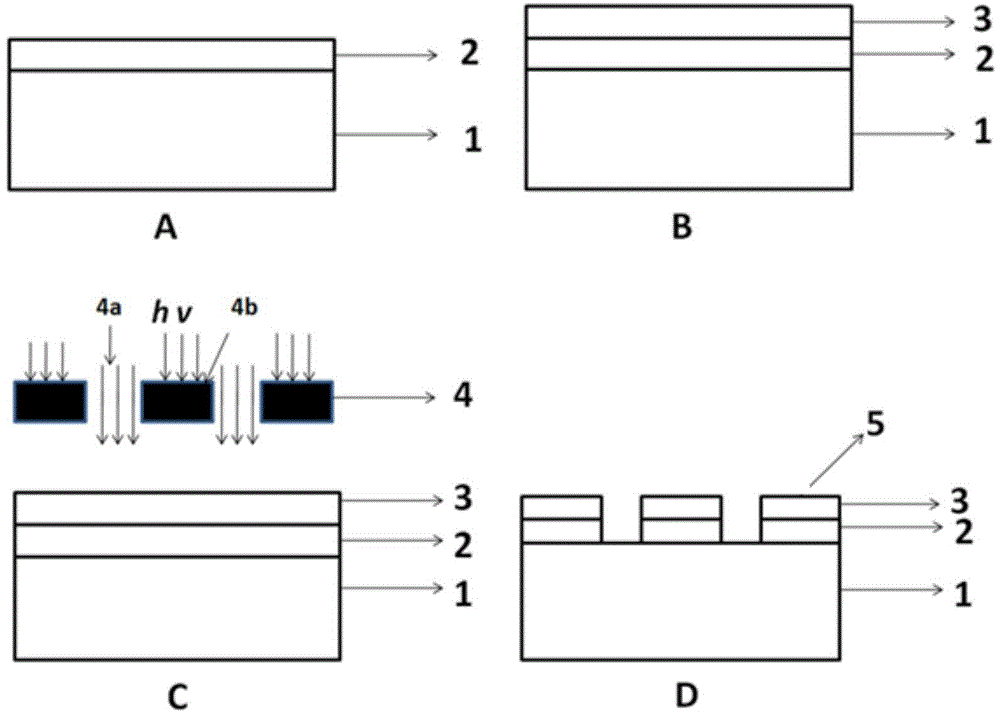

[0097] Figure 5It is the SEM picture of the 2 μm standard line width (period 1:1) obtained by the BARC1-365 glue system in this example after 365nm ultraviolet exposure, where picture a is the SEM picture obtained after direct coating of 365 glue and exposure, and picture b is the picture The partial cross-sectional view of the line width of a, from Figure b, it can be seen that the photoresist is directly spin-coated on the substrate after exposure without adding BARC material, due to the influence of reflected light and standing waves, etc., the photolithographic effect is not good; Figure c is The SEM image obtained after applying 365 glue on BARC1 and exposing it. Figure d is a partial cross-sectional view of the line width in figure c. It can be seen from f...

Embodiment 3

[0099] 1) Preparation of BARC material 2

[0100] 60mg (9.082×10 -5 mol) 2,2-bis(4-hydroxy-3,5-bis(3,4-dihydroxyphenyl)phenyl)propane (molecular weight 660.67g / mol) molecular glass compound (shown in formula V), 6mg PAG (N-hydroxynaphthalimide trifluoromethanesulfonic acid) (accounting for 10% of molecular glass compound quality), 6mg light absorber anthracene (accounting for 10% of molecular glass compound quality), mix in test tube after weighing, then add 0.3mL of 4mg / mL anti-acid diffusing agent TOA (TOA accounts for 2% of the mass of the acid generator) prepared with PGMEA solvent, mix the above substances, add 0.7mL PGMEA solvent, and stir ultrasonically for more than 1 hour to make it evenly mixed to form Component c, pipette 0.776mL (3.632×10 -3 mol, and the molecular glass compound molar ratio is 1:40) 1,4-cyclohexyldimethanol divinyl ether (as shown in the following formula VIII, molecular weight 196.29g / mol, density 0.919g / mL), dissolved in 1mL PGMEA Form compone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com