Production system for producing fumed silica by utilizing silicon tetrachloride

A fumed white carbon black and production system technology, applied in the direction of silicon oxide, silicon dioxide, etc., can solve the problems of poor absorption effect, decreased hydrogen chloride absorption effect, and high temperature of the absorption liquid, so as to shorten the gap and improve the tail gas recovery effect , the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

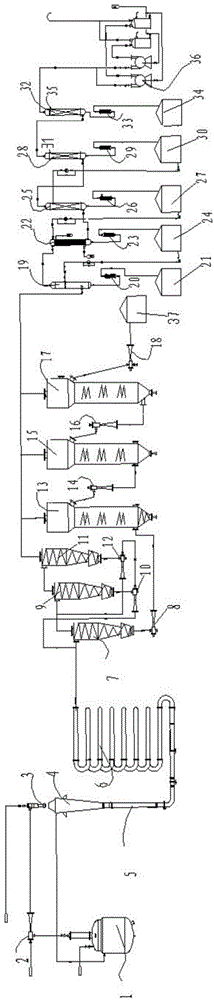

[0034] Below in conjunction with accompanying drawing, the production system of the present invention utilizing silicon tetrachloride to produce fumed white carbon black is described in detail.

[0035] Such as figure 1 As shown, a production system utilizing silicon tetrachloride to produce fumed silica includes a gasification tank 1, the inlet of the gasification tank 1 is connected to the raw material storage tank, the outlet of the gasification tank 1 and the inlet of the ejector Connection, the injector in the present embodiment adopts Venturi tube 2. The working fluid inlet of the Venturi tube 2 is connected to the outlet of the compressed air storage tank, the material inlet of the Venturi tube 2 is connected to the outlet of the gasification tank, the material outlet of the Venturi tube 2 is connected to an inlet of the nozzle 3, and the high-speed flow The air will bring the gasified silicon tetrachloride into the nozzle 3; the other inlet of the nozzle 3 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com