A kind of silica sol combined with wet spraying material

A technology of wet spraying and silica sol, which is applied in the field of unshaped refractory materials, can solve the problems of increased voids, reduced molar volume, and rebound of large particles, so as to prevent the expansion of micro-cracks, improve various properties, and improve fracture toughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

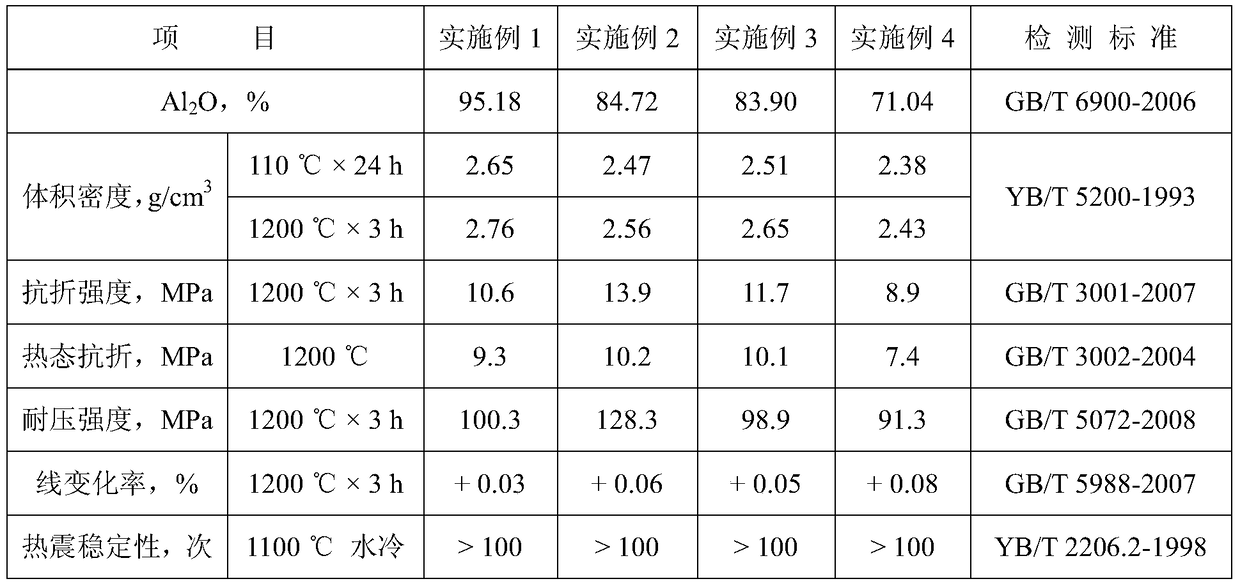

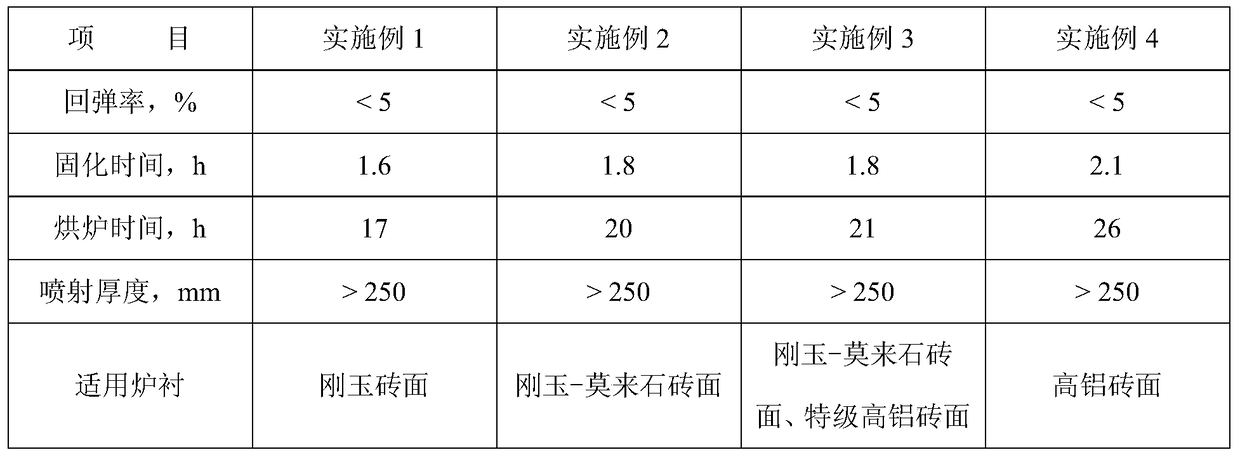

Embodiment 1

[0040] A silica sol combined wet spraying material, which is composed of main raw materials and external components; the main raw materials and their mass percentages are: corundum granules 70%, corundum powder 25%, alumina micropowder (≤2μm 2%, ≤5μm 3%) 5%. The mass percentages of additional components and the total mass of the above-mentioned main raw materials are: retarder (dextrin) 0.4% (that is, the amount of dextrin added is 0.4% of the total mass of corundum granules, corundum powder and alumina micropowder), Dispersant (polyethylene glycol polycondensate 0.7%, sodium hexametaphosphate 0.8%) 1.5%, coagulant (aluminum chloride saturated solution) 0.5%, silica sol 10%.

[0041] Wherein, the mass percentages of the four particle gradations of the corundum granular material in the granular material are 10%, 20%, 30%, and 40% in sequence.

[0042] The above-mentioned preparation method of silica sol combined with wet spraying material comprises the following steps:

[004...

Embodiment 2

[0048] A silica sol combined wet spraying material, which is composed of main raw materials and external components; the main raw materials and their mass percentages are: corundum granules 52%, bauxite powder 40%, alumina micropowder (≤2μm 4%, ≤5μm 4% )8%. The mass percentages of additional components and the total mass of the above-mentioned main raw materials are: retarder (carboxymethyl cellulose) 0.8%, dispersant (polyethylene glycol polycondensate 0.8%, sodium hexametaphosphate 0.5%) 1.3 %, coagulant (aluminum phosphate saturated solution) 0.8%, silica sol 12%.

[0049] Wherein, the mass percentages of the four particle gradations of the corundum pellets in the pellets are 16%, 30%, 30%, and 24% in sequence.

[0050] Preparation process: with embodiment 1.

[0051] Construction method: with embodiment 1.

Embodiment 3

[0053] A silica sol combined wet spraying material, which is composed of main raw materials and external components; the main raw materials and their mass percentages are: 30% of corundum granules, 30% of mullite granules, 15% of corundum powder, 15% of alumina powder, Alumina fine powder (≤2μm 2%, ≤5μm 8%) 10%. The mass percentages of the additional components and the total mass of the above-mentioned main raw materials are: retarder (dextrin) 0.6%, dispersant (sodium hexametaphosphate) 1.0%, coagulant (aluminum phosphate saturated solution) 0.6%, silicon Sol 11%.

[0054] Wherein, the mass percentages of the four particle gradations of the corundum pellets in the corundum pellets are 10%, 25%, 30%, and 35% in sequence. The mass percentages of the four particle gradations of the mullite granular material in the mullite granular material are 10%, 25%, 30%, and 35% in sequence.

[0055] Preparation process: with embodiment 1.

[0056] Construction method: with embodiment 1. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com