Ethylene/tetrafluoroethylene copolymer powder and method for preparing same

A tetrafluoroethylene and copolymer technology, which is applied in the field of ethylene/tetrafluoroethylene copolymer powder and its preparation, can solve the problems of decreased mechanical properties of the copolymer, easy discoloration, cracking of the polymer film, etc., and achieves tensile strength. and excellent elongation at break, low residual amount of powder solvent, and the effect of preventing the generation of air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

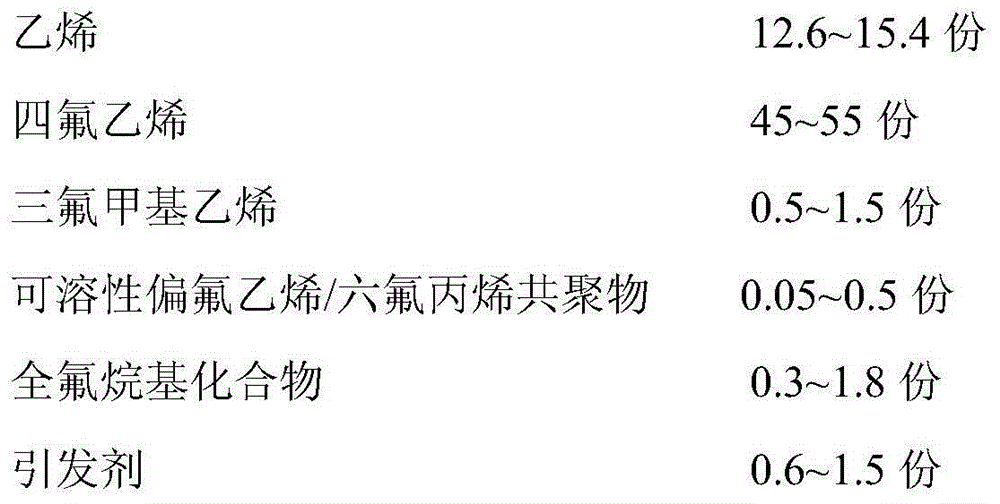

Method used

Image

Examples

Embodiment 1

[0024] (1) Solution copolymerization

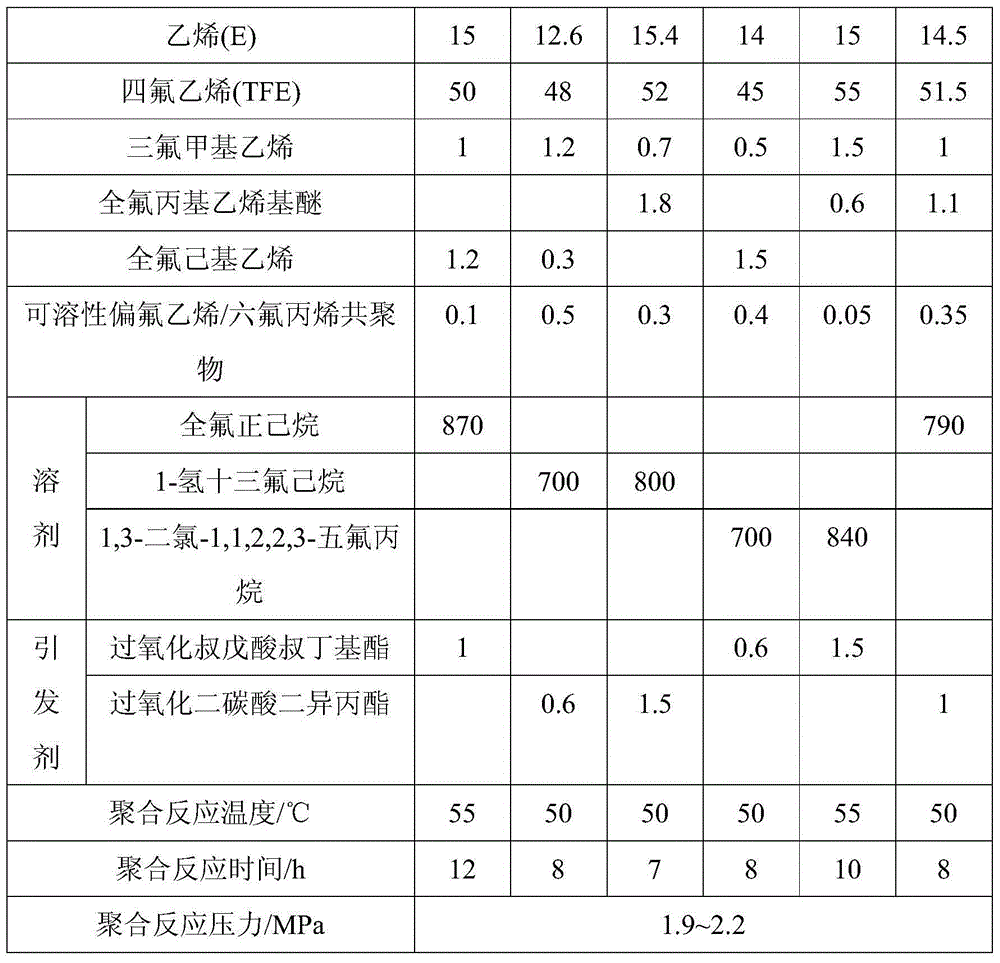

[0025]Through the cycle process of vacuuming and high-purity nitrogen replacement, the high-pressure reactor is deoxidized so that the oxygen content in the reactor is less than 18ppm, and then 771 parts of perfluoro-n-hexane, 1 part of trifluoromethylethylene, 1.2 parts of perfluorohexylethylene, 0.1 part of soluble vinylidene fluoride / hexafluoropropylene copolymer, stirred to dissolve. Then import the mixed gas of ethylene (E) / tetrafluoroethylene (TFE) with a mass ratio of 15 / 50 to make the pressure in the kettle rise to 2.1MPa, then stir and heat up to 55°C, and inject 100 parts of 1% super Oxidation of tert-butyl pivalate in perfluoro-n-hexane to initiate polymerization. As the reaction progresses, the pressure drops, and the E / TFE mixed gas with a mass ratio of 15 / 50 is continuously introduced to maintain the pressure between 1.9 and 2.2 MPa. When the amount of ethylene (E) / tetrafluoroethylene (TFE) mixed gas introduced reached 65 ...

Embodiment 2~6

[0029] Step (1) The polymerization formula and process parameters are shown in Table 1, and the rest of the preparation method is the same as in Example 1.

[0030] See Table 2 for the yields and performance indexes of the powders obtained in Examples 1-6. in:

[0031] 【Powder Yield】

[0032] First obtain the solid content A% of the ETFE solution through the solid content test, calculate the theoretical powder yield a from the product of the feed amount and the solid content A%, and weigh the actual powder yield b after precipitation treatment. The powder yield is obtained from the quotient of b and a.

[0033] [melting point]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com