A kind of preparation method and application of bacterial spore functional microspheres

A technology of spores and bacteria, which is applied in the field of preparation of bacterial spore functional microspheres, can solve the problems of human and environmental hazards, high cost, loss of activity, etc., and achieve the effect of stable mechanical rigid structure, stable and reliable performance, and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1 (preparation embodiment)

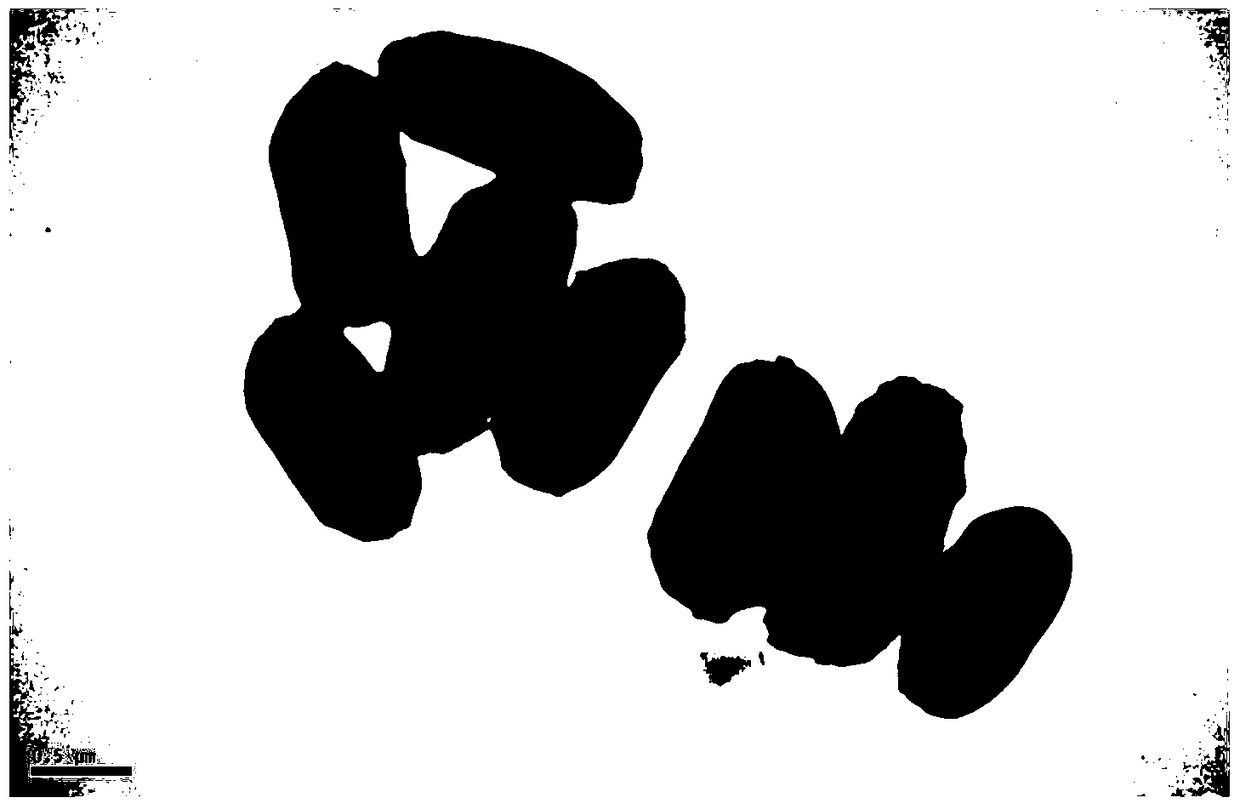

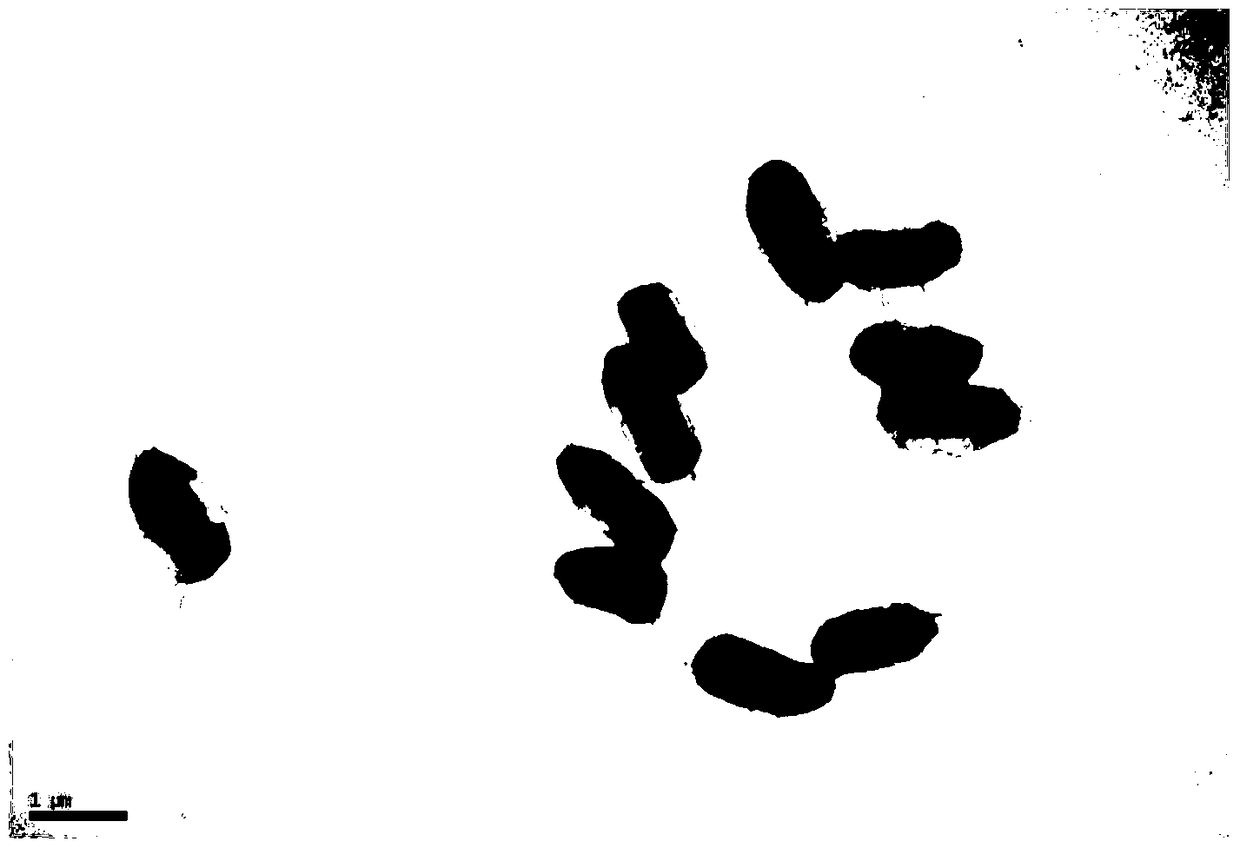

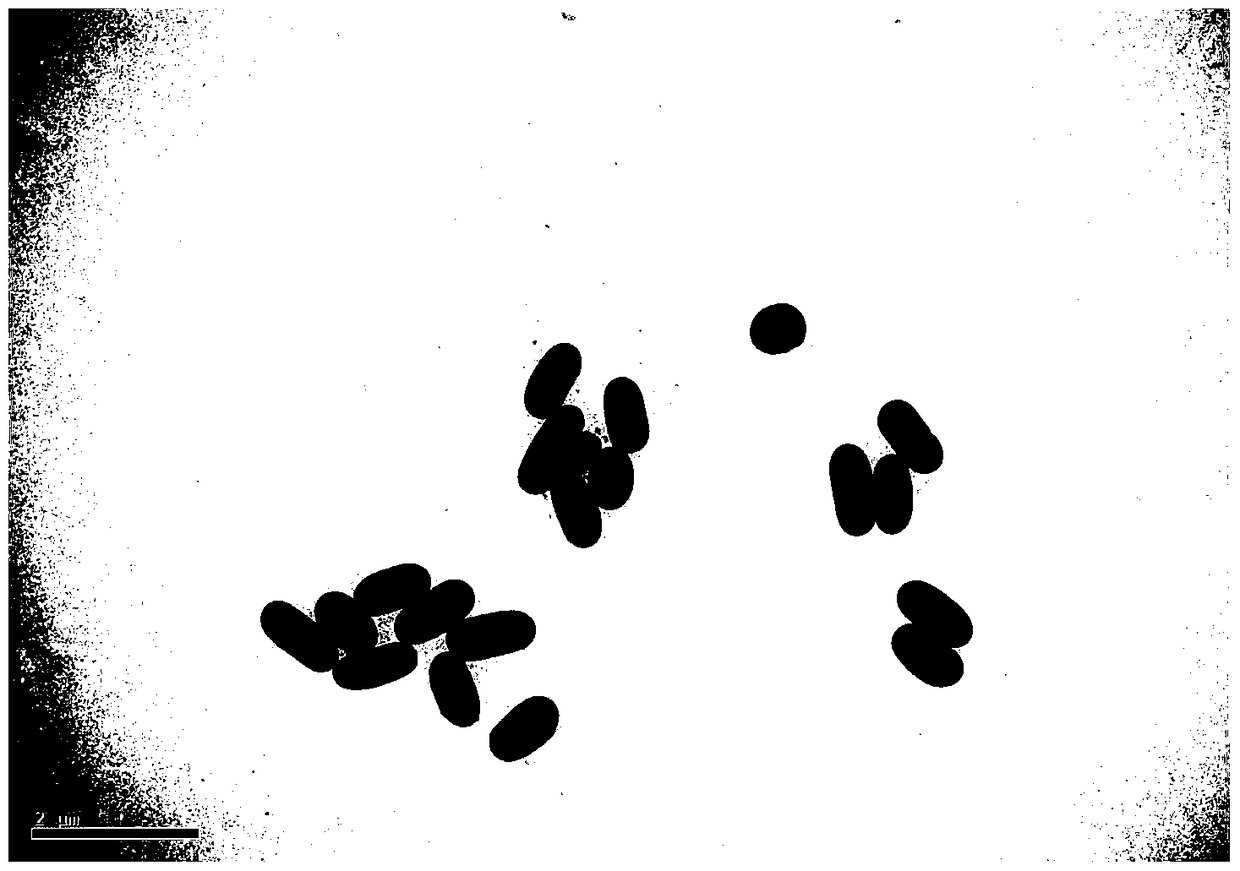

[0044] In this example, spores of Bacillus megaterium, Bacillus subtilis and Bacillus amyloliquefaciens were used as starting materials for preparing functional microspheres (but not limited to the above materials).

[0045] The specific steps are as follows:

[0046] (1) Prepare LB liquid medium and LB solid medium, and sterilize the prepared LB liquid medium and LB solid medium at 121° C. for 30 min. Activate the above three bacillus strains with LB liquid medium for 4-6 hours, when OD 600 When = 0.6, add 200uL of activated bacterial solution to each petri dish and spread evenly, then cultivate in a 37°C incubator. The bacillus spores cultured for 3-10 days were collected, washed with deionized water and centrifuged, and repeated 2-5 times.

[0047] (2) The spores were resuspended with deionized water, and an appropriate concentration (preferably in the range of 10 8 ~10 11 spores / mL) were subpackaged in centrifuge tubes, u...

Embodiment 2( application Embodiment 1

[0051] See Example 1 for the method of preparing spore microspheres. On the basis of Example 1, the obtained biological spore microspheres are further processed, and the specific steps are as follows:

[0052] (1) Prepare the following metal nanoparticles (materials) in the laboratory: colloidal gold (particle size 15nm), colloidal silver (particle size 10-15nm), colloidal platinum (particle size 5nm), colloidal palladium (particle size 5nm), Cubic palladium (particle size 20-30nm).

[0053] (2) After mixing the prepared metal nanoparticles with the spore suspension prepared in Example 1 (the preferred concentration range is 10 8 ~10 10 / mL), placed in a constant temperature shaker and incubated with shaking, so that the metal nanoparticles were adsorbed on the surface of the spores to form composite microspheres of spores@metal nanoparticles.

[0054](3) The three kinds of natural spores (including but not limited to the above-mentioned spores), the processed spores, metal...

Embodiment 3( application Embodiment 2

[0057] The spore@colloidal gold composite microsphere prepared in Example 2 was used as a carrier for the detection of ApxIVA antibody in the serum infected by Actinobacillus pleuropneumoniae. The specific application steps are as follows:

[0058] (1). Take 100 μL of microspheres and react with 200 μL of ApxIVA antigen protein to immobilize ApxIVA antigen protein on the surface of the microspheres.

[0059] (2) Bovine serum albumin (BSA) solution was used as a blocking agent to block the microspheres labeled with ApxIVA antigenic protein to occupy active sites on the surface of the microspheres that were not adsorbed by the antigenic protein to reduce non-specific reactions.

[0060] (3) Add 200 μL of the serum to be tested. If the serum contains the corresponding antibody, it can have a specific immune reaction with the antigen protein to form a microsphere-antigen-antibody complex.

[0061] (4) Add 200 μL of biotin-labeled goat anti-pig IgG to carry out the second immune re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com