Outdoor overhead ageing-resistant insulating polyolefin cable material and preparation method thereof

A kind of polyolefin cable material, anti-aging technology, used in insulators, organic insulators, plastic/resin/wax insulators and other directions, can solve the problems of poor mechanical properties, poor aging resistance, poor weather resistance, etc., to improve aging resistance, improve Mechanical properties, the effect of increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] An aging resistant insulating polyolefin cable material for outdoor overhead use, prepared from the following parts by weight (kg) of raw materials: ethylene-vinyl acetate copolymer 60, chlorosulfonated polyethylene 30, triisopropylphenyl phosphate 4. Acetyl tri-n-butyl citrate 4, magnesium hydroxide 8, diisodecyl phthalate 40, butadienyl triethoxysilane 6, organic chromium complex 2, tribasic lead sulfate 6, right Phenylenediamine 5, nano calcium carbonate 30, β-diketone 6, ammonium polyphosphate 12, emulsified silicone oil 7, fluoroalkyl polyether modified polysiloxane 5, zinc stearate 7, nano calcium dioxide 5 , Paraffin 6, hexadecyl dimethyl tertiary amine 8.

[0015] A preparation method of anti-aging insulating polyolefin cable material for outdoor aerial use, which is characterized in that it comprises the following steps:

[0016] (1) Magnesium hydroxide, butadienyl triethoxy silane, organic chromium complex, p-phenylenediamine, fluoroalkyl polyether modified polysi...

Embodiment 2

[0020] An aging resistant insulating polyolefin cable material for outdoor overhead use, prepared from the following parts by weight (kg) of raw materials: ethylene-vinyl acetate copolymer 70, chlorosulfonated polyethylene 35, triisopropylphenyl phosphate 5. Acetyl tri-n-butyl citrate 4.5, magnesium hydroxide 9, diisodecyl phthalate 45, butadienyl triethoxysilane 7, organic chromium complex 3, tribasic lead sulfate 7, right Phenylenediamine 6, Nano Calcium Carbonate 35, β-Diketone 8, Ammonium Polyphosphate 13, Emulsified Silicone Oil 7.5, Fluoroalkyl Polyether Modified Polysiloxane 6, Zinc Stearate 8, Nano Calcium Dioxide 6.5 , Paraffin 7.5, hexadecyl dimethyl tertiary amine 10.

[0021] The preparation method is the same as in Example 1.

Embodiment 3

[0023] An aging resistant insulating polyolefin cable material for outdoor aerial use, prepared from the following parts by weight (kg) of raw materials: ethylene-vinyl acetate copolymer 80, chlorosulfonated polyethylene 40, triisopropylphenyl phosphate 6, Acetyl tri-n-butyl citrate 5, magnesium hydroxide 10, diisodecyl phthalate 50, butadienyl triethoxysilane 8, organic chromium complex 4, tribasic lead sulfate 8, right Phenylene diamine 7, nano calcium carbonate 40, β-diketone 10, ammonium polyphosphate 14, emulsified silicone oil 8, fluoroalkyl polyether modified polysiloxane 7, zinc stearate 9, nano calcium dioxide 8 , Paraffin 9, hexadecyl dimethyl tertiary amine 12.

[0024] The preparation method is the same as in Example 1.

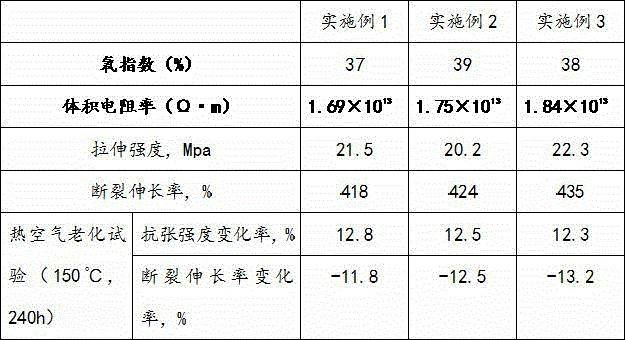

[0025] The performance test results of the anti-aging insulating polyolefin cable material for outdoor overhead use prepared in the foregoing Examples 1-3 are shown in the following table:

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com