High temperature resistance flaming-retardant silicone rubber cable material for electric power and preparing method thereof

A technology of high temperature resistance and silicone rubber, which is applied in the field of high temperature resistance and flame retardant silicone rubber cable material for electric power and its preparation, which can solve the problems of wear resistance, collision resistance, temperature resistance, medium resistance, aging resistance, and flame retardant properties that cannot meet the requirements. Rubber surface damage, loss of performance and other problems, to achieve the effect of increasing flexibility, reducing dosage, and enhancing flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A high-temperature-resistant and flame-retardant silicone rubber cable material for electric power, which is prepared from the following raw materials in parts by weight (kg): methyl vinyl silicone rubber 120, neoprene rubber 10, polyethylene terephthalate 8, Trimethylolpropane Trimethacrylate 4, Magnesium Hydroxide 8, Dicyclohexyl Terephthalate 40, Vinyl Trimethoxysilane 6, NDZ-401 Titanate Coupling Agent 4, Organic Antimony Stabilizer 6. Antioxidant 168 5. Nano-calcium carbonate 50. Phosphite monophenyl diisooctyl 8. Tetrabromobisphenol A 11. Polyoxyethylene polyoxypropanolamine ether 6. Dimethicone 6. Three Antimony oxide 4, calcium stearate 7, graphite fluoride 7, nano titanium dioxide 8.

[0015] A preparation method for high temperature resistant flame retardant silicone rubber cable material for electric power, characterized in that it comprises the following steps:

[0016] (1) Mix antimony trioxide, calcium stearate, graphite fluoride, nano-titanium dioxide, o...

Embodiment 2

[0020] A high-temperature-resistant and flame-retardant silicone rubber cable material for electric power, which is prepared from the following raw materials in parts by weight (kg): methyl vinyl silicone rubber 130, neoprene rubber 15, polyethylene terephthalate 10, Trimethylolpropane Trimethacrylate 4.5, Magnesium Hydroxide 9, Dicyclohexyl Terephthalate 45, Vinyl Trimethoxysilane 6.5, NDZ-401 Titanate Coupling Agent 5, Organic Antimony Stabilizer 7. Antioxidant 168 6. Nano-calcium carbonate 55, phenylenedi-isooctyl phosphite 9, tetrabromobisphenol A 12, polyoxyethylene polyoxypropanolamine ether 7.5, dimethyl siloxane 7, three Antimony oxide 4.5, calcium stearate 8, graphite fluoride 8.5, nano titanium dioxide 10.

[0021] The preparation method is the same as in Example 1.

Embodiment 3

[0023] A high-temperature-resistant and flame-retardant silicone rubber cable material for electric power, which is prepared from the following raw materials in parts by weight (kg): methyl vinyl silicone rubber 140, neoprene rubber 20, polyethylene terephthalate 12, Trimethylolpropane Trimethacrylate 5, Magnesium Hydroxide 10, Dicyclohexyl Terephthalate 50, Vinyl Trimethoxysilane 7, NDZ-401 Titanate Coupling Agent 6, Organic Antimony Stabilizer 8. Antioxidant 168 7. Nano-calcium carbonate 60, 1-phenyl-diisooctyl phosphite 10, tetrabromobisphenol A 13, polyoxyethylene polyoxypropanolamine ether 9, dimethyl siloxane 8, three Antimony oxide 5, calcium stearate 9, graphite fluoride 10, nano titanium dioxide 12.

[0024] The preparation method is the same as in Example 1.

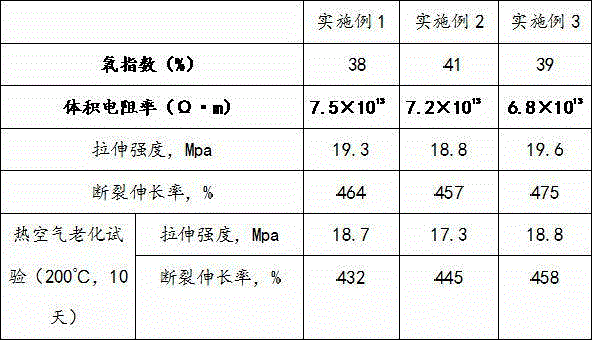

[0025] The performance test results of the high-temperature-resistant flame-retardant silicone rubber cable material for electric power obtained in the above-mentioned embodiments 1-3 are shown in the followin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com