A method for enhancing the stabilization process of heavy metals in anaerobic digested sludge

An anaerobic digestion and heavy metal technology, applied in biological sludge treatment, pyrolysis treatment sludge, by-product vaporization, etc., can solve the problems of weak acid impact resistance, weakened adsorption performance, poor stability, etc., and achieve uniform distribution, Reduce ecological risk and promote the effect of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

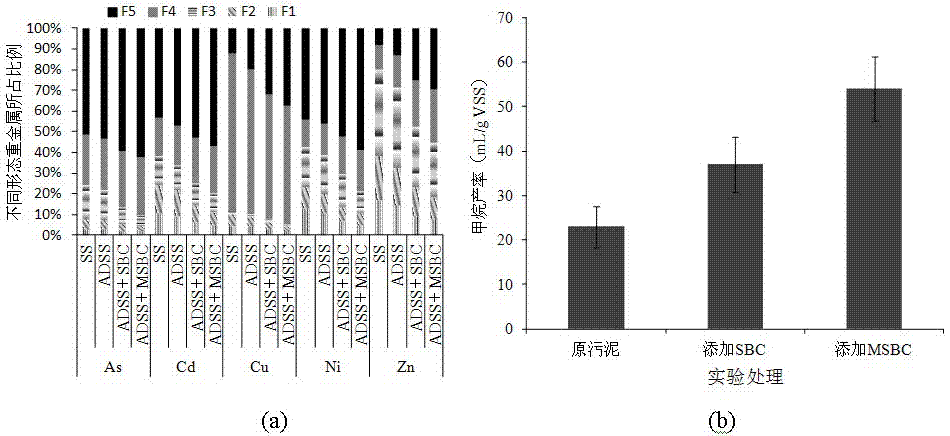

Embodiment 1

[0026] The concrete steps of this embodiment are as follows:

[0027] Preparation of modified sludge biochar enhancer: The raw sludge used to make sludge biochar was taken from the dewatered sludge of a sewage treatment plant in Hefei (the organic matter content was 65.4%, and the main heavy metal content was lower than that of sludge for agricultural use. According to the standard (GB4284-1984), the sludge biochar preparation equipment is a special quartz vacuum tube furnace. After loading the raw sludge, it is first purged with 99.99% nitrogen for 30 minutes to empty the air, resulting in anoxic state, and the pyrolysis temperature The temperature is 650℃, and the duration is 4h. After cooling, it is ground, passed through a 100-mesh screen, and then modified by glass fiber infiltration, and finally prepared as a heavy metal stabilization enhancer in the process of sludge anaerobic digestion.

[0028]This implementation case adopts the medium temperature anaerobic digestion ...

Embodiment 2

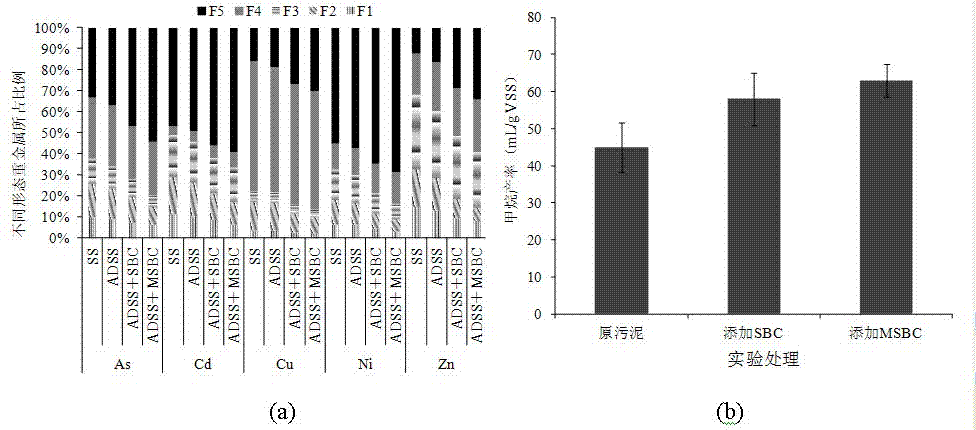

[0031] In order to verify the effect of this method on the stabilization of heavy metals by anaerobic digestion of sludge with high heavy metal content, this implementation case is taken from the residual sewage of a sewage treatment plant that simultaneously undertakes domestic sewage from residents and wastewater from surrounding industrial parks (water volume ratio is 6:4). Mud (about 80% water content), its main mud index: pH 7.2, TS 8.7%, VS 3.2%, main heavy metal content (unit: mg / kg): As (11.76), Cd (1.28), Cr (1205.32 ), Cu (304.88), Ni (201.38), Pb (29.22), Zn (2864.21), the organic content of the sludge is lower than that of Example 1, but the main heavy metal content is obviously higher. The modified sludge biochar (MSBC) used, as well as the experimental equipment and experimental methods are the same as those in Example 1. Experimental results such as figure 2 shown. Depend on figure 2 (a) It can be clearly seen that even for sludge with a higher concentratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com