Method for resource utilization of pineapple peel and electrolytic manganese anode slime

A technology for electrolytic manganese and anode slime, which is applied to the improvement of process efficiency, element selenium/tellurium, etc., can solve the problems of difficult recycling of selenium, environmental pollution, high price, etc., and achieves simple wet processing process, reducing pollution problems, Fast response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

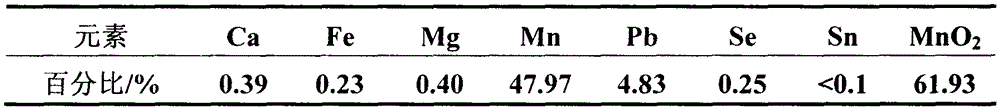

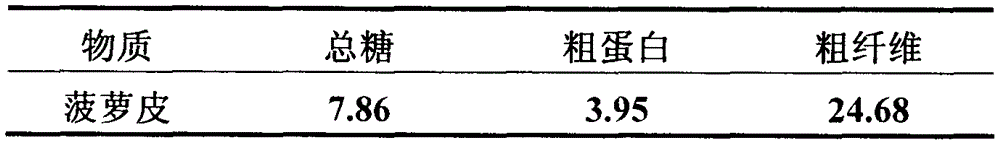

[0021] The electrolytic manganese anode slime is crushed to pass through a 100-mesh sieve (the composition is shown in Table 1); after the pineapple skin is naturally air-dried, it is crushed to pass through a 60-mesh sieve (the composition is shown in Table 2); the electrolytic manganese anode is added to the reactor Pineapple peel with 0.18 times the weight of the mud, and add electrolytic manganese anode slime, then add 2.0 times the weight of electrolytic manganese anode slime with sulfuric acid with a concentration of 98%, prepare the slurry with water until the liquid-solid ratio is 5; stir and react at 90°C for 5 hours to obtain Reactive leaching solution, the leaching rate of Mn in the manganese anode slime reaches 95.68%, and the lead content in the residue is 46.02%. Add 0.4g / L scrap iron filings to the leaching solution after filtering the residue, and add activated carbon according to the iron-carbon ratio of 2:1, stir and react at 98°C for 80min, and selenium is de...

Embodiment 2

[0027] The electrolytic manganese anode slime is crushed to pass through a 100-mesh sieve (the composition is shown in Table 1); after the pineapple skin is naturally air-dried, it is crushed to pass through a 60-mesh sieve (the composition is shown in Table 2); the electrolytic manganese anode is added to the reactor Pineapple peel with 0.20 times the weight of the mud, and add electrolytic manganese anode slime, then add 1.8 times the weight of electrolytic manganese anode slime with sulfuric acid with a concentration of 98%, prepare the slurry with water until the liquid-solid ratio is 4; stir and react at 95°C for 4 hours to obtain The leaching rate of Mn in the manganese anode slime reaches 96.13% in the reaction leaching solution, and the lead content in the residue is 46.69%. Add 0.6g / L scrap iron filings to the leaching solution after filtering the residue, and add activated carbon according to the iron-carbon ratio of 3:1, stir and react at 70°C for 30min, and selenium...

Embodiment 3

[0029] The electrolytic manganese anode slime is crushed to pass through a 100-mesh sieve (the composition is shown in Table 1); after the pineapple skin is naturally air-dried, it is crushed to pass through a 60-mesh sieve (the composition is shown in Table 2); the electrolytic manganese anode is added to the reactor Pineapple peel with 0.24 times the weight of the mud, and add electrolytic manganese anode slime, then add 2.5 times the weight of electrolytic manganese anode slime with sulfuric acid with a concentration of 98%, prepare the slurry with water until the liquid-solid ratio is 6; stir and react at 98°C for 6 hours to obtain The leaching rate of Mn in the manganese anode slime reaches 98.13% in the reaction leaching solution, and the lead content in the residue is 47.23%. Add 0.8g / L scrap iron filings to the leaching solution after filtering the residue, and add activated carbon according to the iron-carbon ratio of 3:1, stir and react at 50°C for 120min, and seleniu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com