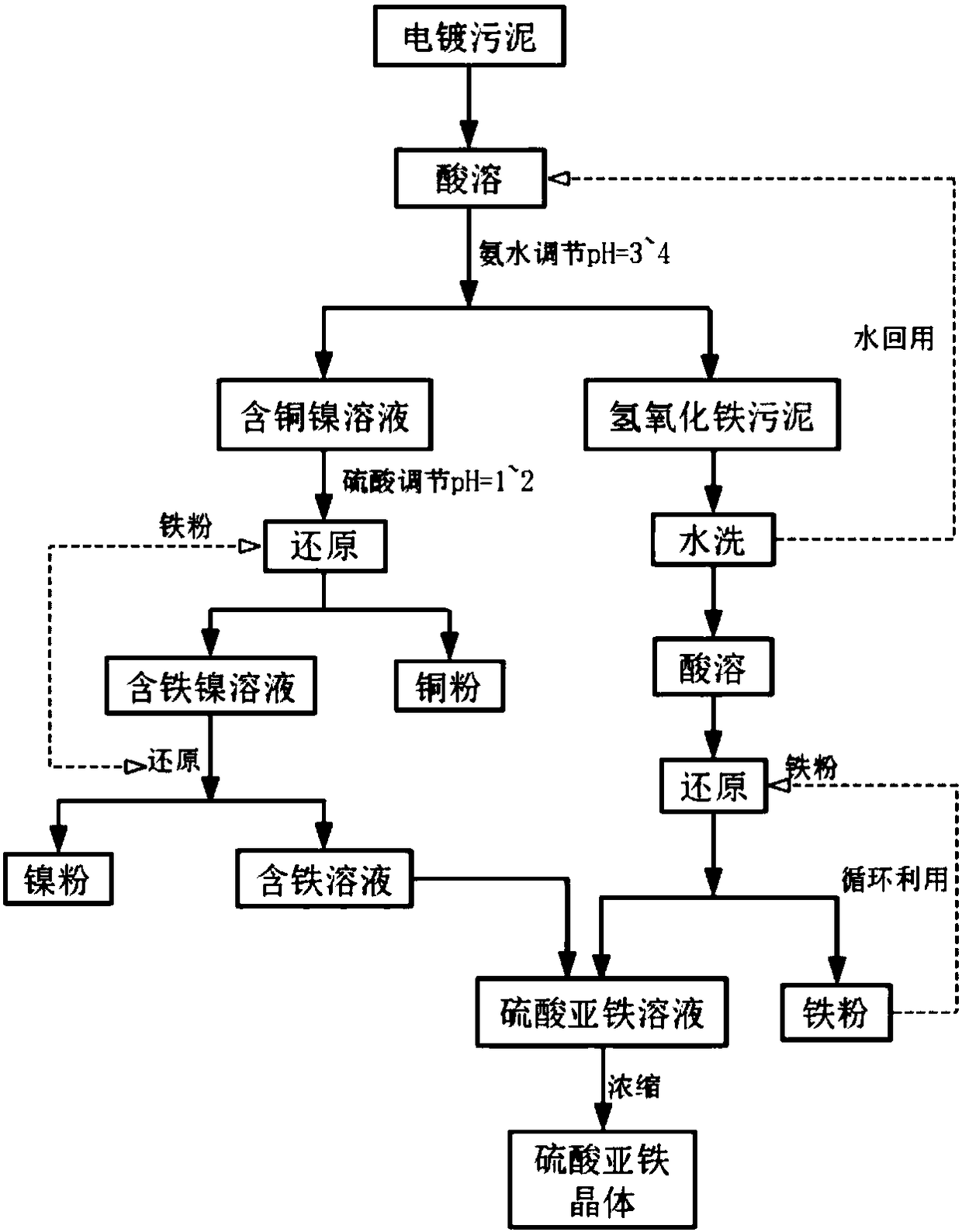

A method for recycling electroplating sludge with high iron content and low copper and nickel content

A technology for electroplating sludge and iron content, which is applied in the direction of ferric sulfate and the improvement of process efficiency, and achieves the effects of mild process, simple process and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Take 400kg of electroplating sludge, slowly add sulfuric acid solution with a mass concentration of 20%, stir and dissolve for 1 hour, measure the end point pH of the leaching solution = 0.4, slowly add ammonia water to adjust the solution pH = 3, let it settle for 3 hours, press filter to obtain hydrogen Iron sludge and filtrate; iron hydroxide sludge is beaten and washed according to the solid-to-liquid ratio of 1:1.5, and washed for 2 hours each time. After the ferric hydroxide mud, 0.5 times of iron powder of the amount of iron in the solution is added thereto, stirred and filtered at room temperature to obtain ferrous sulfate solution, and the filtrate is concentrated, recrystallized, and centrifuged to finally obtain industrial-grade standard ferrous sulfate (purity 87.95 %); and the filtrate is added at normal temperature with 80% sulfuric acid to adjust the pH to 1, wherein iron powder is added twice, each addition is 1 to 1.5 times the amount of copper or nickel...

Embodiment 2

[0034] Take 600kg of electroplating sludge, slowly add sulfuric acid solution with a mass concentration of 20%, stir and dissolve for 2 hours, measure the end point pH of the leaching solution = 0.7, slowly add ammonia water to adjust the pH of the solution solution = 3.5, let it settle for 4 hours, press filter to obtain hydrogen oxide Iron sludge and filtrate; iron hydroxide sludge is beaten and washed at a solid-to-liquid ratio of 1:1.8, and washed for 2.5 hours each time. The beaten water after washing is reused until the electroplating sludge is dissolved, and the sulfuric acid solution with a mass concentration of 20% is used for dissolution Ferric hydroxide mud after washing, 0.8 times iron powder of the amount of iron in the solution is added therein, room temperature stirring and filtering obtain ferrous sulfate solution, filtrate concentration, recrystallization, centrifugation finally obtain and reach industrial grade standard ferrous sulfate (purity 91.25%); and the...

Embodiment 3

[0037] Take 800kg of electroplating sludge, slowly add sulfuric acid solution with a mass concentration of 20%, stir and dissolve for 3 hours, measure the end point pH of the leaching solution = 1, slowly add ammonia water to adjust the solution pH = 4, let it settle for 5 hours, press filter to obtain hydrogen Iron sludge and filtrate; iron hydroxide sludge is beaten and washed at a solid-to-liquid ratio of 1:2, and washed for 3 hours each time. After the ferric hydroxide mud, 1.0 times iron powder of the amount of iron in the solution is added thereto, stirred and filtered at room temperature to obtain ferrous sulfate solution, and the filtrate is concentrated, recrystallized, and centrifuged to finally obtain industrial-grade standard ferrous sulfate (purity 89.78 %); the filtrate is added at normal temperature with 80% sulfuric acid to adjust the pH to 2, wherein iron powder is added twice, each addition is 1 to 1.5 times of the amount of copper or nickel in the filtrate, f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk density | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com