Zr2WP2O12/polyimide composite material with low thermal expansion coefficient and preparation method therefor

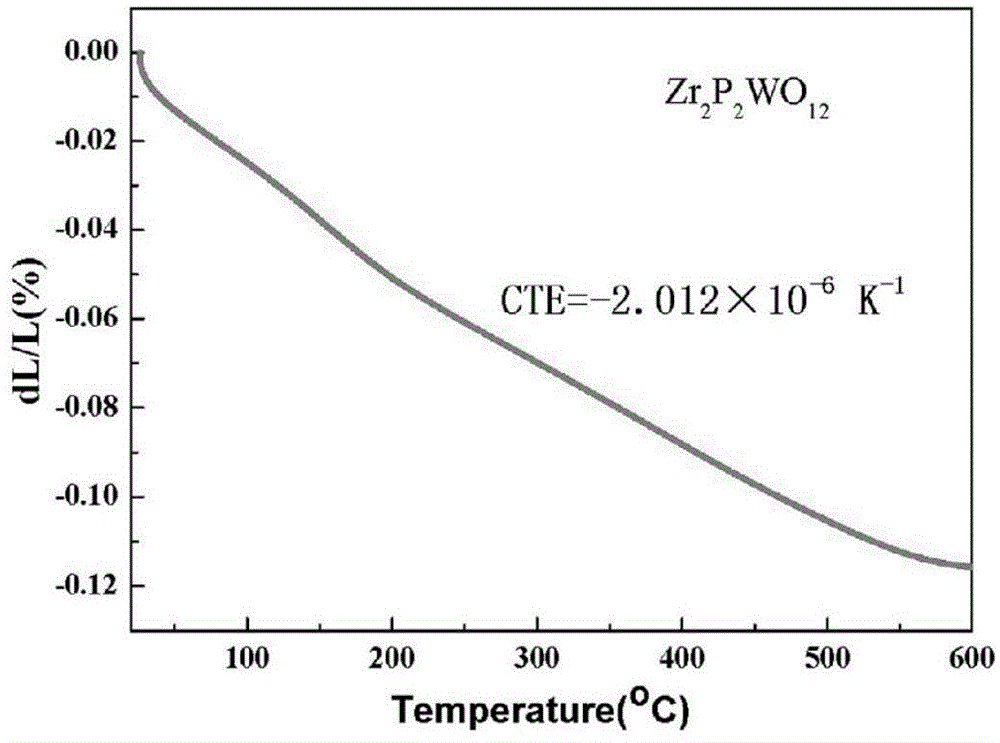

A low thermal expansion coefficient, zr2wp2o12 technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of reduced thermal expansion coefficient of polyimide, limited, unsatisfactory effect, etc., to reduce thermal expansion coefficient and control thermal expansion. coefficient, effect of good thermal stability and dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

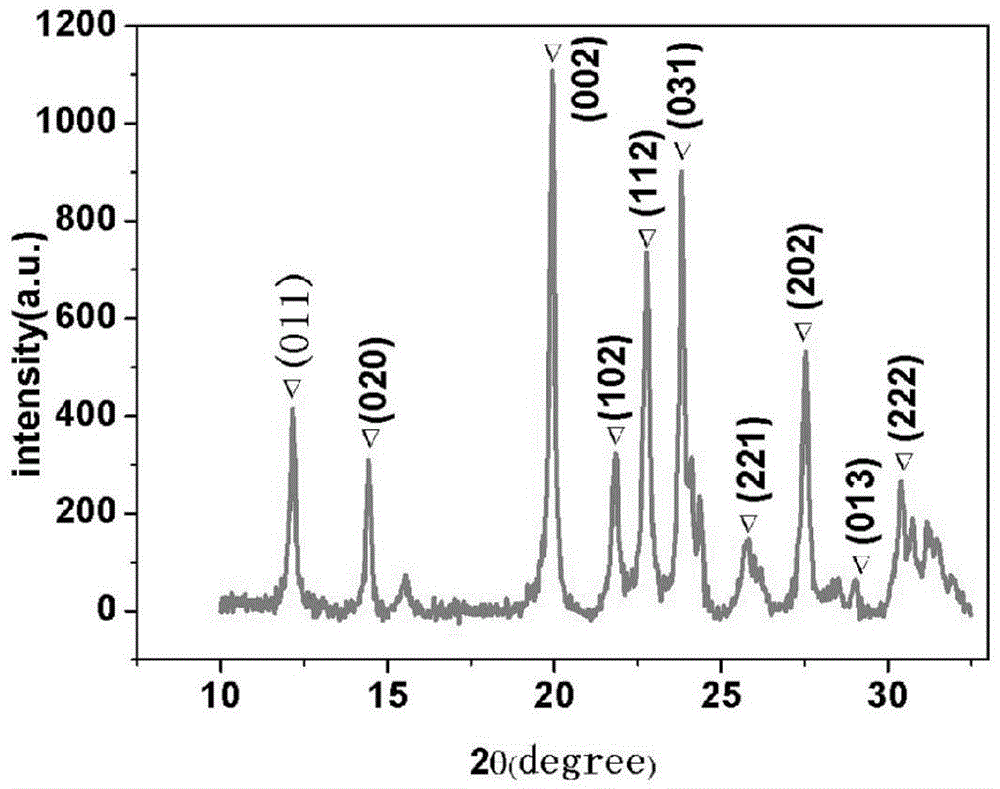

[0043] Low thermal expansion coefficient Zr of the present invention 2 WP 2 o 12 / Polyimide composite material is made of polyimide and zirconium phosphotungstate Zr 2 WP 2 o 12 Composite preparation;

[0044] The polyimide is prepared from 4,4-diaminodiphenyl ether monomer ODA and pyromellitic anhydride PMDA according to a conventional in-situ polymerization method;

[0045] The ratio of the zirconium phosphotungstate to the total weight of 4,4-diaminodiphenyl ether monomer, pyromellitic anhydride and zirconium phosphotungstate is 30%.

Embodiment 2

[0047] Low coefficient of thermal expansion Zr described in Example 1 of the present invention 2 WP 2 o 12 The preparation method of / polyimide composite material, the detailed steps of this preparation method are as follows:

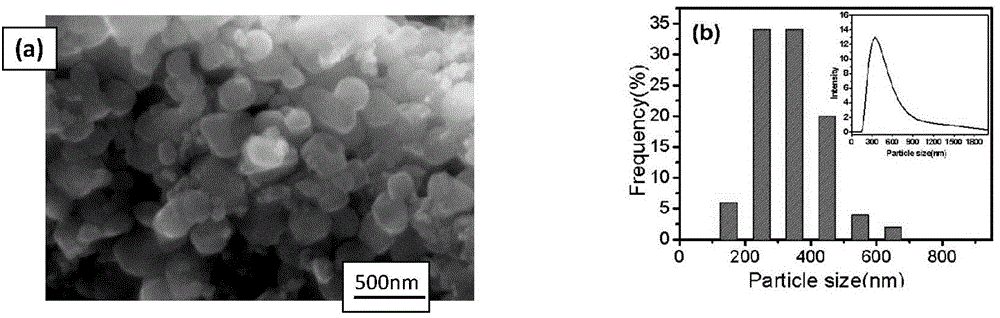

[0048] a. First, dissolve 1g of 4,4-diaminodiphenyl ether monomer ODA in 20mL of polar solvent N,N-dimethylformamide DMF; then add 0.9192g of zirconium phosphotungstate ZWP with a particle size of 360-400nm Powder, then add 1.145g pyromellitic anhydride PMDA in 4 times for mixing, the resulting mixed solution is stirred and reacted at room temperature for 4.5h, and a mixed solution of polyimide precursor PAA and zirconium phosphotungstate ZWP is obtained, namely PAA / ZWP / DMF;

[0049] b. Dry the mixed solution obtained in step a in a drying oven at 100°C for 24 hours, place the dried product in a resistance box, control the resistance box to heat up at a rate of 4°C / min, and keep it warm when the temperature rises to 180°C 1h to remove the organic so...

Embodiment 3

[0057] Low thermal expansion coefficient Zr of the present invention 2 WP 2 o 12 / Polyimide composite material is made of polyimide and zirconium phosphotungstate Zr 2 WP 2 o 12Composite preparation;

[0058] The polyimide is prepared from 4,4-diaminodiphenyl ether monomer ODA and pyromellitic anhydride PMDA according to a conventional in-situ polymerization method;

[0059] The ratio of the zirconium phosphotungstate to the total weight of 4,4-diaminodiphenyl ether monomer, pyromellitic anhydride and zirconium phosphotungstate is 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com