A kind of cross-linked pectin fiber and preparation method thereof

A pectin and fiber technology, which is applied in fiber treatment, fiber chemical characteristics, rayon chemical post-treatment, etc., can solve the problems of non-crosslinked and water-soluble, etc., to achieve rich biological activity, broad application prospects, good biophase Capacitance and water resistance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention provides a kind of preparation method of cross-linked pectin fiber, the method comprises:

[0034] Step 1: mixing the pectin aqueous solution and the polyethylene oxide aqueous solution, then adding a surfactant and a co-solvent to obtain a mixed solution, and spinning the mixed solution to obtain electrospun nanofibers;

[0035] Step 2: Crosslinking the electrospun nanofibers obtained in Step 1 to obtain crosslinked nanofibers;

[0036] Step 3: washing the cross-linked nanofibers obtained in Step 2 to obtain cross-linked pectin fibers.

[0037] According to the present invention, pectin and polyoxyethylene are formulated into pectin aqueous solution and polyoxyethylene aqueous solution respectively first, the mass percent concentration of described pectin aqueous solution is preferably 2%~10%, according to the present invention, described pectin The source of pectin is not particularly limited, and is preferably citrus, lemon, apple, sunflower, beet or g...

Embodiment 1

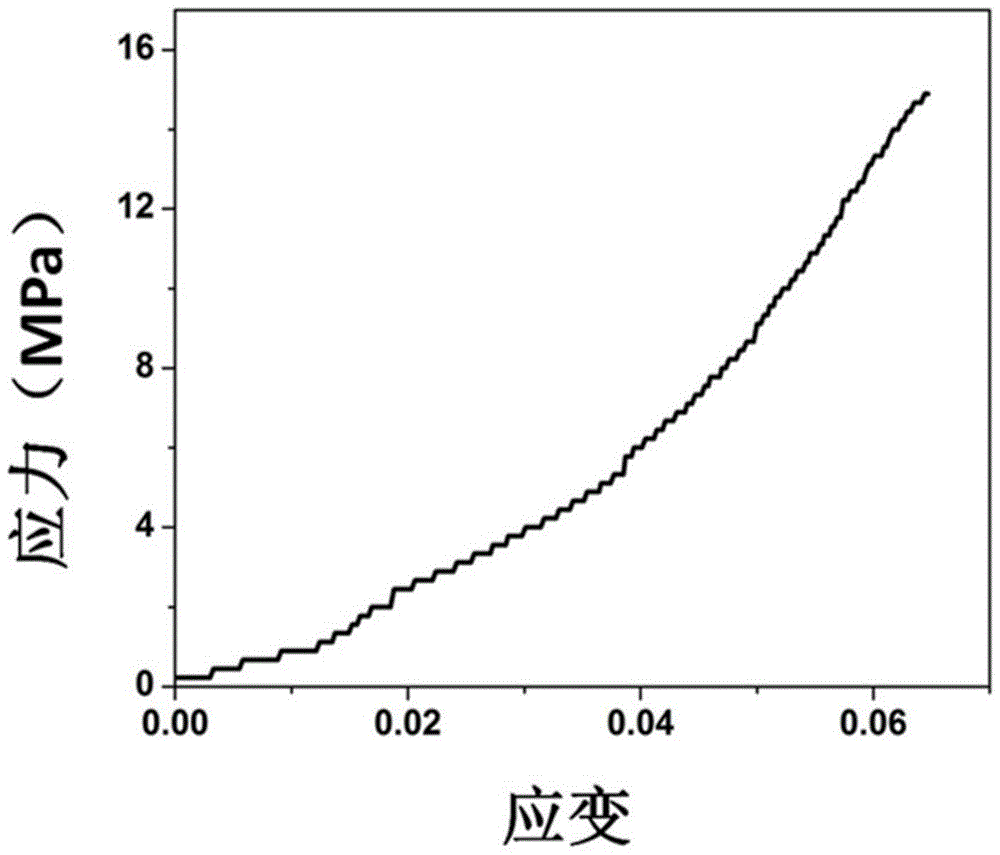

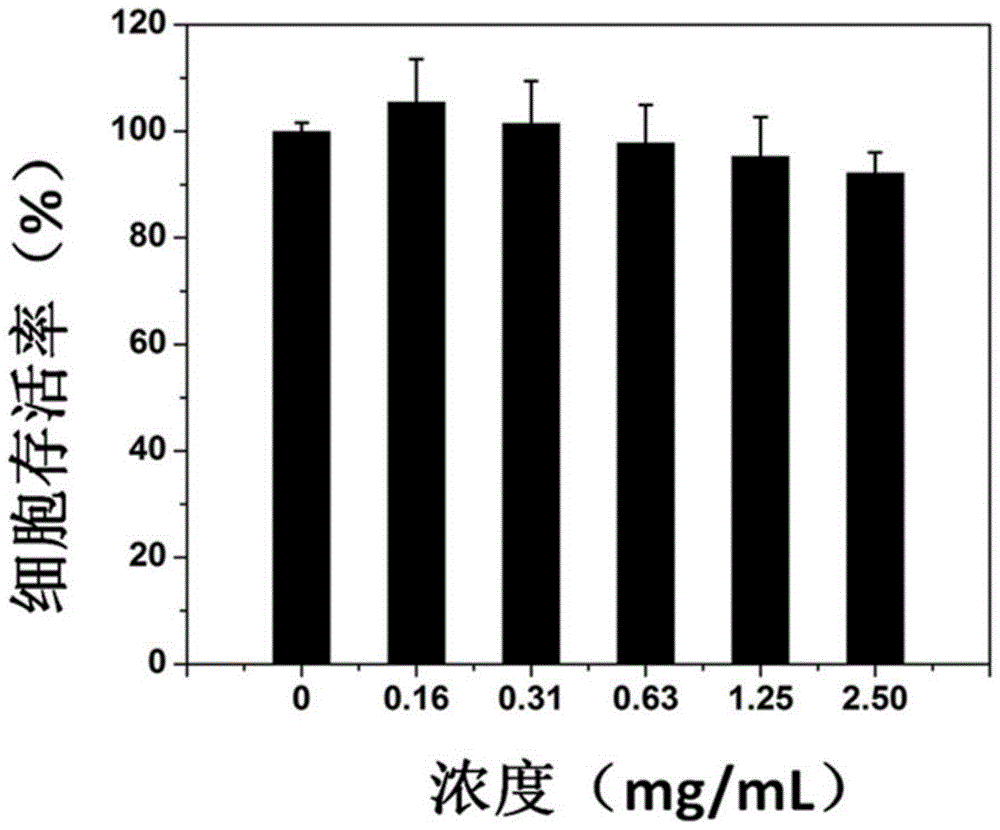

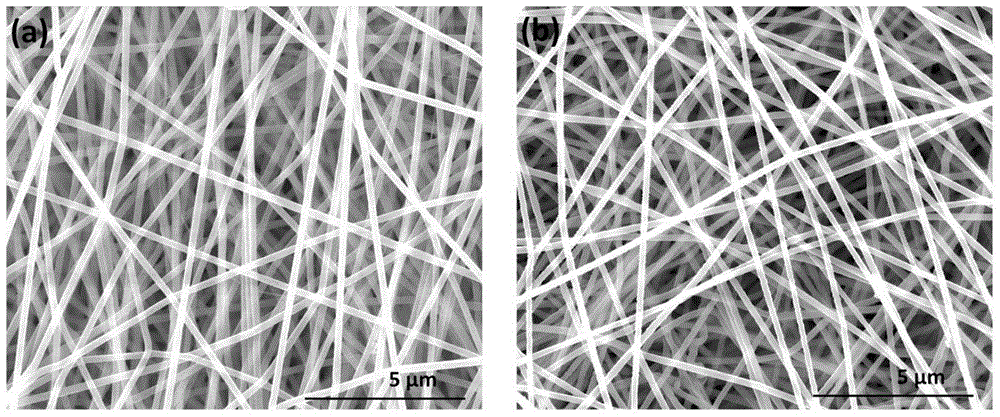

[0057] Example 1: Ca 2+ Ionically cross-linked low-ester sunflower pectin fiber

[0058] 1) Electrospinning: first prepare respectively 5% low-ester sunflower pectin aqueous solution (molecular weight is 210,000, degree of esterification 44%) and 5% polyoxyethylene (molecular weight is 5,000,000) aqueous solution, then according to pectin and The mass ratio of polyoxyethylene is 95:5. The low-ester sunflower pectin aqueous solution and polyoxyethylene aqueous solution are mixed, and adding mass percentage concentration is 1% triton 100 and mass percentage concentration is 5% dimethyl sulfoxide , the mixed solution was stirred at room temperature for 3 hours and then stood overnight to obtain a uniform mixed solution without bubbles. The above mixed solution was spun under a high-voltage electric field of 10kV, and the fibers were collected at a distance of 15cm from the spinneret to obtain electrospun nanofibers. fiber;

[0059] 2) Ca 2+ Ionic physical cross-linking: soak 2...

Embodiment 2

[0064] Embodiment 2: through Zn successively 2+ Low-ester amidated apple pectin fiber with ionic physical crosslinking and glutaraldehyde chemical crosslinking

[0065] 1) Electrospinning: first prepare respectively 4% low-ester amidated apple pectin aqueous solution (molecular weight is 300,000, degree of esterification 27%, degree of amidation 23%) and 4% polyethylene oxide (molecular weight is 2,000,000 ) aqueous solution, according to the mass ratio of pectin and polyethylene oxide, the low-ester amidated apple pectin aqueous solution and polyethylene oxide aqueous solution are mixed according to the mass ratio of pectin and polyethylene oxide, and the addition of poloxamer 127 and mass percentage concentration of 0.5% The concentration is 10% dimethylformamide, the mixed solution is stirred at room temperature for 5 hours, and left standing overnight to obtain a uniform mixed solution without bubbles. The above mixed solution is spun under a high-voltage electric field of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com