Production method of silver nanowire transparent conductive film

A technology of transparent conductive film and nano-silver wire, which is applied to the conductive layer, circuit, and electrical components on the insulating carrier, can solve the problems of large limitations of transparent conductive film of nano-silver wire, poor product function, and difficulty in popularization. Achieve the effects of good electrical conductivity, cost reduction, performance and yield improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A production method of nano-silver wire transparent guide glass, comprising the following steps:

[0045] (1) Select the substrate: select a transparent glass sheet with a specification of 450mm×550mm×0.7mm;

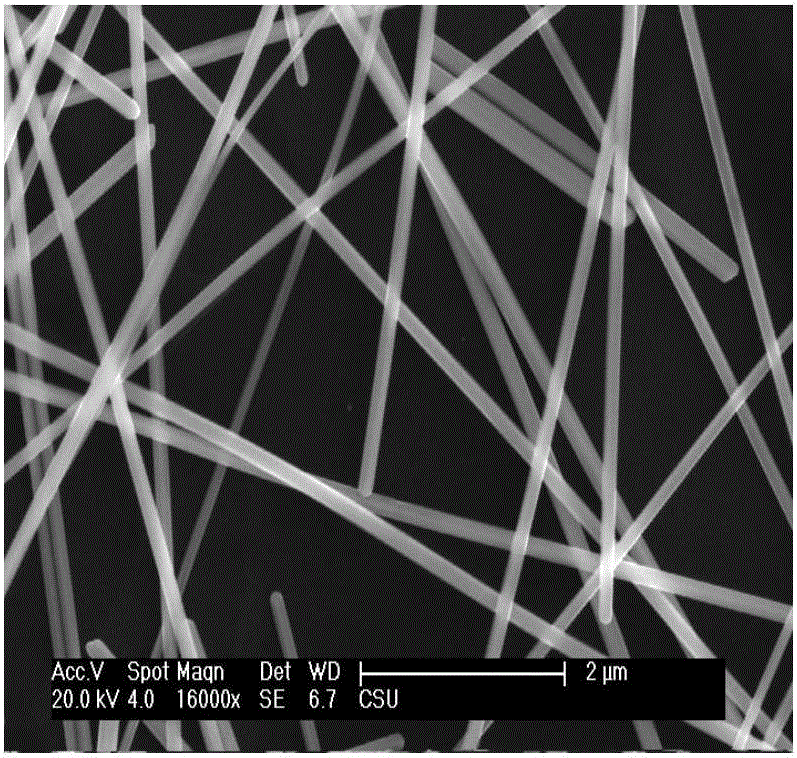

[0046] (2) Prepare nano-silver wire suspension, adopt alcohol reduction method, mix silver nitrate, cupric chloride, polyvinylpyrrolidone and glycerol by the mass ratio of 1:0.0002:3:250 and inject in the reactor, react The kettle was evenly heated to about 200°C and continued to react for 4 hours. After natural cooling, silver nanowires with a diameter of 30-40 nanometers and a length of 10-30 μm were obtained. Then, by centrifugation, the solvent, dispersant and other impurities mixed in the silver nano wires are removed through secondary water purification and primary ethanol purification. Finally, the purified silver nanowires were stored in absolute ethanol.

[0047] (3) To prepare titanium dioxide sol, after mixing tetrabutyl titanate, ethanol and hydrochl...

Embodiment 2

[0056] A production method of nano-silver wire transparent guide glass, comprising the following steps: (1) selecting a base material: selecting a transparent glass sheet whose specification is 450mm×550mm×0.7mm;

[0057] (2) Prepare the nano-silver wire suspension, adopt the alcohol reduction method, mix the silver nitrate, copper chloride, polyvinylpyrrolidone and glycerol by the mass ratio of 1:0.0003:4:300 and inject it into the reactor, and the reaction The kettle is evenly heated to about 220° C., and the reaction is continued for 4 hours. After natural cooling, nano-silver wires with a diameter of 25-35 nanometers and a length of 10-20 μm are obtained. Then, by centrifugation, the solvent, dispersant and other impurities mixed in the silver nano wires are removed through secondary water purification and primary ethanol purification. Finally, the purified silver nanowires were stored in absolute ethanol.

[0058] (3) Prepare titania sol, adopt sol-gel method, after mixi...

Embodiment 3

[0065] Embodiment 3 A kind of production method of nano-silver wire conductive TFT

[0066] The main steps and methods of this embodiment are the same as those of Embodiment 1, the difference being:

[0067] (1) A TFT (Thin Film Transistor) sheet with a specification of 670mm×350mm×0.1mm is selected as the base material.

[0068] (2) Nano-silver wire coating solution and oxide sol must be coated on the front side of the TFT sheet.

[0069] (3) The baking temperature is 80-130° C., and the baking time is 150-240 minutes.

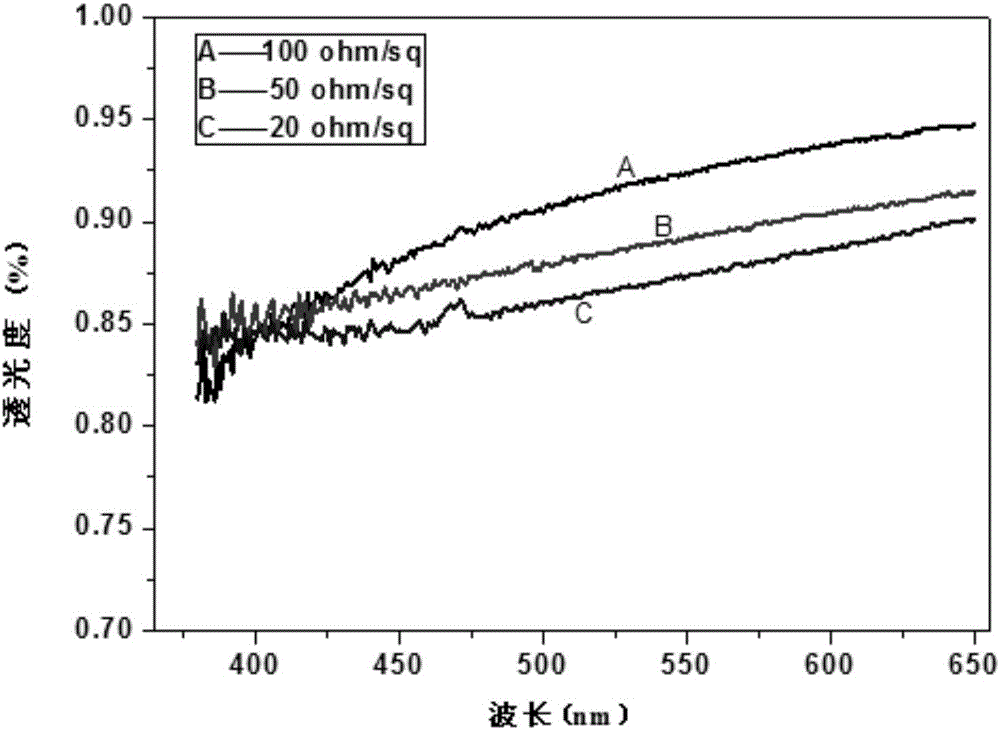

[0070] (4) The surface resistance of the finished product is 20-50 ohm / sq, and the surface hardness is 7-8H.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com