Combined reagent for reverse flotation of microgranular iron ore magnetic concentrate and application method thereof

A technology of magnetic separation concentrate and combined reagents, which is applied in flotation, solid separation, etc., can solve the problem of low index of reverse flotation concentrate, and achieve the effect of convenient preparation, simple operation and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

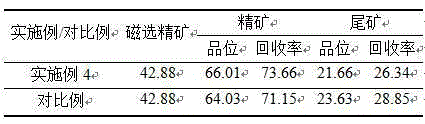

Examples

Embodiment 1

[0023] The application method of the microfine iron ore magnetic separation concentrate reverse flotation combination agent, its specific steps are as follows:

[0024] (1) After the iron ore with Fe grade of 25-32wt% is crushed and ground to a fineness of less than 74μm, which accounts for more than 95% of the total material weight, magnetic separation is used to obtain a magnetic separation concentrate with an iron grade of 42.88wt%; the magnetic separation concentrate The useful iron minerals in the ore are hematite and a small amount of magnetite and siderite. The gangue minerals are mainly quartz, chlorite and a small amount of ferrodolomite that is easy to muddy. The chemical multi-element analysis results are shown in Table 1.

[0025] Table 1 Chemical multi-element analysis of magnetic separation concentrate

[0026]

[0027] (2) Adjust the magnetic separation concentrate obtained in step (1) into a slurry with a weight percentage concentration of 35%~40% for revers...

Embodiment 2

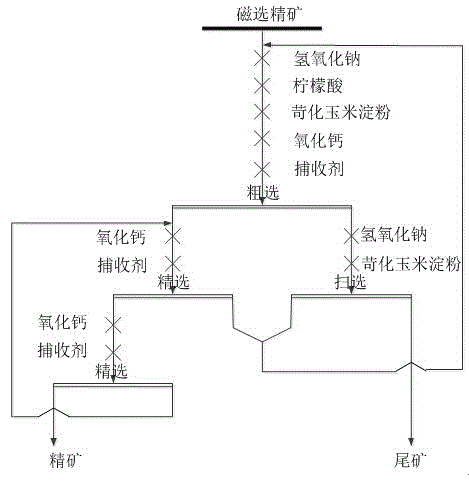

[0034] Such as figure 1 As shown, the application method of the microfine iron ore magnetic separation concentrate reverse flotation combination agent, its concrete steps are as follows:

[0035] (1) After the iron ore with Fe grade of 25-32wt% is crushed and ground to a fineness of less than 74μm, which accounts for more than 95% of the total material weight, magnetic separation is used to obtain a magnetic separation concentrate with an iron grade of 42.88wt%; the magnetic separation concentrate The useful iron minerals in the ore are hematite and a small amount of magnetite and siderite. The gangue minerals are mainly quartz, chlorite and a small amount of ferrodolomite that is easy to muddy. The chemical multi-element analysis results are shown in Table 1.

[0036] Table 1 Chemical multi-element analysis of magnetic separation concentrate

[0037]

[0038] (2) Adjust the magnetic separation concentrate obtained in step (1) into a slurry with a weight percentage concent...

Embodiment 3

[0045] Such as figure 1 As shown, the application method of the microfine iron ore magnetic separation concentrate reverse flotation combination agent, its concrete steps are as follows:

[0046] (1) After the iron ore with Fe grade of 25-32wt% is crushed and ground to a fineness of less than 74μm, which accounts for more than 95% of the total material weight, magnetic separation is used to obtain a magnetic separation concentrate with an iron grade of 42.88wt%; the magnetic separation concentrate The useful iron minerals in the ore are hematite and a small amount of magnetite and siderite. The gangue minerals are mainly quartz, chlorite and a small amount of ferrodolomite that is easy to muddy. The chemical multi-element analysis results are shown in Table 1.

[0047] Table 1 Chemical multi-element analysis of magnetic separation concentrate

[0048]

[0049] (2) Adjust the magnetic separation concentrate obtained in step (1) into a slurry with a weight percentage concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com