Halogen-free and flame-retardant ABS material and preparation method thereof

A technology of ABS material and flame retardant, which is applied in the field of halogen-free flame retardant ABS material and its preparation, can solve the problems of high flame retardant addition and large influence of product thermal deformation temperature, etc., and achieve low and excellent comprehensive heat resistance The effect of physical and mechanical properties and good impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

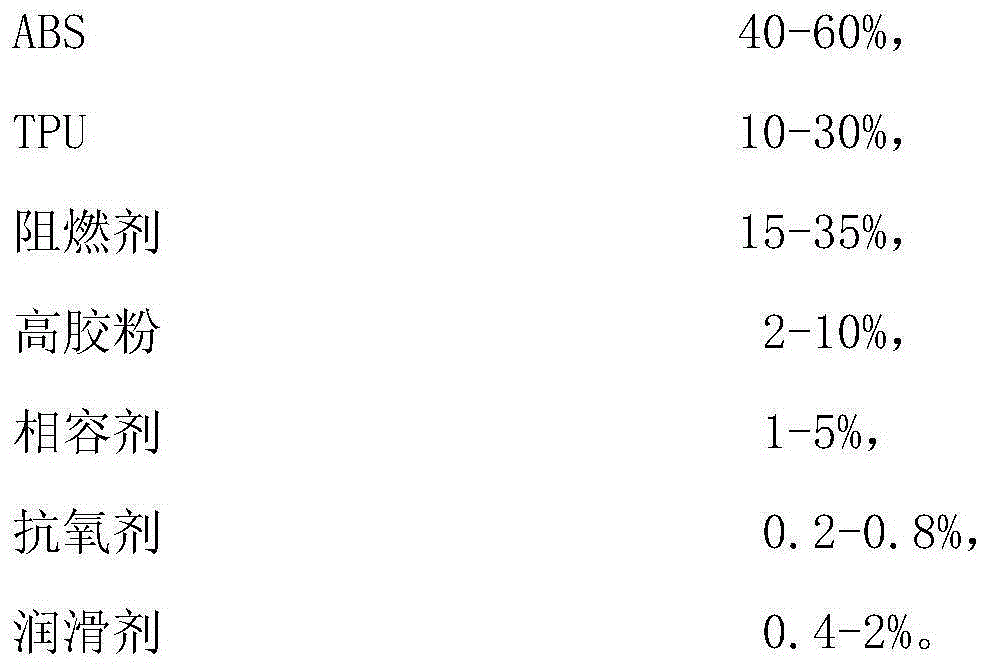

[0022] A halogen-free flame-retardant ABS material, comprising the following components by weight percentage:

[0023]

[0024]

[0025] The antioxidant is compounded by antioxidant 1010 and antioxidant 168 with a mass ratio of 1:2.

[0026] The lubricant is a mixture of EBS accounting for 0.6% of the total weight of the halogen-free flame-retardant ABS material and 0.6% of magnesium stearate accounting for the total weight of the halogen-free flame-retardant ABS material.

[0027] A preparation method of a halogen-free flame-retardant ABS material, comprising the following steps:

[0028] (1) take each raw material by above-mentioned weight ratio;

[0029] (2) Put ABS, TPU, compatibilizer and antioxidant into the mixer and mix for 3 minutes to obtain the mixture I;

[0030] (3) Add the flame retardant, high rubber powder and lubricant to the mixture I, mix in the mixer for 3 minutes, and discharge to obtain the mixture II;

[0031] (4) Put the compound II into the tw...

Embodiment 2

[0033] A halogen-free flame-retardant ABS material, comprising the following components by weight percentage:

[0034]

[0035] The antioxidant is compounded by antioxidant 1010 and antioxidant 168 with a mass ratio of 1:2.

[0036] The lubricant is a mixture of 1% ethylene bis stearamide (EBS) and 0.2% of the total weight of the halogen-free flame-retardant ABS material. .

[0037] The preparation method of the above-mentioned halogen-free flame-retardant ABS material is the same as that in Example 1.

Embodiment 3

[0039] A halogen-free flame-retardant ABS material, comprising the following components by weight percentage:

[0040]

[0041] The antioxidant is compounded by antioxidant 1010 and antioxidant 168 with a mass ratio of 1:2.

[0042] The lubricant is a mixture of 0.2% ethylene bis stearamide (EBS) and 1% of the total weight of the halogen-free flame-retardant ABS material. .

[0043] The preparation method of the above-mentioned halogen-free flame-retardant ABS material is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com