A kind of clay soil type saline-alkali soil improvement method using hydrolyzed polyacrylonitrile soil subbing agent

A technology for hydrolyzing polyacrylonitrile and soil improvement, applied in the fields of land preparation methods, applications, agricultural machinery and implements, etc., can solve the problem of not being able to simultaneously improve the permeability and water holding capacity of clay soil type saline-alkali soil, and the number of microorganisms has not been obtained. Effective improvement, soil nutrient and fertility loss, etc., to achieve the effect of increasing water release rate, increasing utilization rate of phosphate fertilizer, and increasing the number of microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

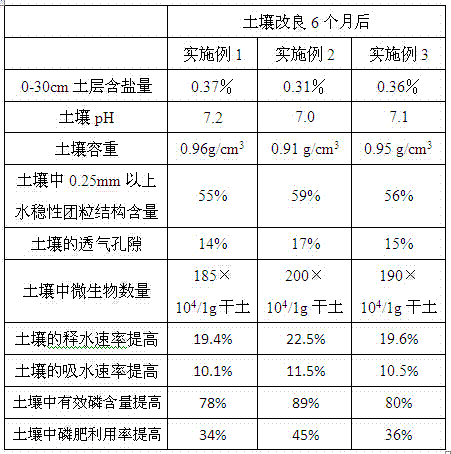

Embodiment 1

[0033] Embodiment 1 A kind of hydrolyzed polyacrylonitrile soil subsoiling agent

[0034] Described soil deep loosening agent, the mass ratio of each component is:

[0035] 16 parts of hydrolyzed polyacrylonitrile, 10 parts of Kunshan stone, 4 parts of Bacillus lateralis, 3 parts of phosphate solubilizing bacteria, 5 parts of amino acid salt, 6 parts of biochar, 4 parts of calcium-based bentonite, 0.6 parts of humic acid water-retaining agent, carbonic acid 9 parts of ammonium hydrogen, 11 parts of corn straw powder, and 25 parts of chicken manure.

[0036] The amino acid salts are serine salts, leucine salts and aspartic acid salts with a mass ratio of 1:2:2.

[0037] The corn stalk powder has a particle size of 80-100 mesh and a carbon-to-nitrogen ratio of 35-38:1.

[0038] The mass percentage of organic matter in the chicken manure is greater than 45%.

Embodiment 2

[0039] Embodiment 2 A kind of hydrolyzed polyacrylonitrile soil subsoiling agent

[0040] Described soil deep loosening agent, the mass ratio of each component is:

[0041] 18 parts of hydrolyzed polyacrylonitrile, 13 parts of Kunshan stone, 5 parts of Bacillus lateralis, 7 parts of phosphate solubilizing bacteria, 8 parts of amino acid salt, 10 parts of biochar, 7 parts of calcium-based bentonite, 0.8 parts of humic acid water retaining agent, carbonic acid 12 parts of ammonium hydrogen, 15 parts of corn straw powder, and 30 parts of chicken manure.

[0042] The amino acid salts are serine salts, leucine salts and aspartic acid salts with a mass ratio of 1:2:2.

[0043] The corn stalk powder has a particle size of 80-100 mesh and a carbon-to-nitrogen ratio of 35-38:1.

[0044] The mass percentage of organic matter in the chicken manure is greater than 45%.

Embodiment 3

[0045] Embodiment 3 A kind of hydrolyzed polyacrylonitrile soil subsoiling agent

[0046] Described soil deep loosening agent, the mass ratio of each component is:

[0047] 22 parts of hydrolyzed polyacrylonitrile, 15 parts of Kunshan stone, 8 parts of Bacillus lateralis, 9 parts of phosphate solubilizing bacteria, 11 parts of amino acid salt, 14 parts of biochar, 13 parts of calcium-based bentonite, 1.2 parts of humic acid water-retaining agent, carbonic acid 16 parts of ammonium hydrogen, 19 parts of corn straw powder, and 35 parts of chicken manure.

[0048] The amino acid salts are serine salts, leucine salts and aspartic acid salts with a mass ratio of 1:2:2.

[0049] The corn stalk powder has a particle size of 80-100 mesh and a carbon-to-nitrogen ratio of 35-38:1.

[0050] The mass percentage of organic matter in the chicken manure is greater than 45%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com