Dried small shrimp laver biscuits and preparation technology thereof

A preparation process and technology of laver, applied in baking, dough processing, baked food and other directions, can solve the problems of complex process, high production energy consumption, and many ingredients of biscuit raw materials, so as to improve immunity, prevent tumors, and delay aging. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

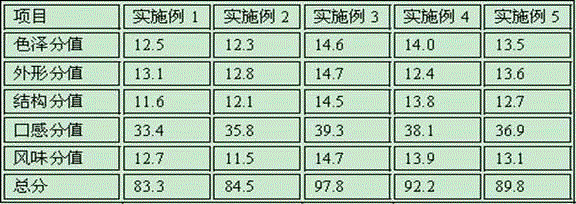

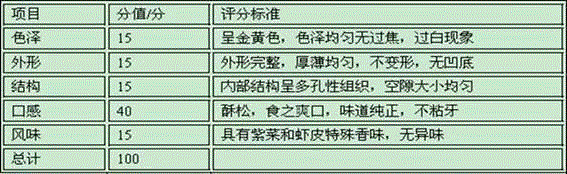

Examples

Embodiment 1

[0026] A shrimp skin seaweed biscuit, which is composed of the following raw materials in parts by weight: 200 parts of flour, 45 parts of eggs, 50 parts of shrimp skin, 40 parts of seaweed, 4 parts of vanilla, 12 parts of vegetable oil, 50 parts of xylitol, 0.8 parts of baking soda, yeast Powder 0.3 part, salt 0.4 part.

[0027] A kind of shrimp skin seaweed biscuit is prepared through the following steps:

[0028] 1) Crush: Wash the selected commercially available shrimp skin with water at 4°C, remove the sediment, then add 5 parts by weight of original millet rice wine, 1 part of ginger powder, and 94 parts of distilled water to soak for 20 minutes to remove the fishy smell. Wash, drain, and air-dry at 70°C, then use a food grinder to make shrimp powder for later use; dry commercially available seaweed at 120°C for 10 minutes, then use a food grinder to make seaweed powder for later use; wash with herbs After draining, chop and set aside;

[0029] 2) Kneading noodles: Put...

Embodiment 2

[0037] A shrimp skin seaweed biscuit, which is composed of the following raw materials in parts by weight: 240 parts of flour, 35 parts of eggs, 60 parts of shrimp skin, 30 parts of seaweed, 5 parts of vanilla, 8 parts of vegetable oil, 80 parts of xylitol, 0.3 parts of baking soda, yeast Powder 0.8 part, salt 0.2 part.

[0038] A kind of shrimp skin seaweed biscuit is prepared through the following steps:

[0039] 1) Crush: Wash the selected commercially available dried shrimps with water at a temperature of 20°C to remove the sediment, then add 10 parts by weight of original millet rice wine, 0.5 parts of ginger powder, and 89.5 parts of distilled water to soak for 15 minutes to remove the fishy smell. Wash, drain, and air-dry at 50°C, then use a food grinder to make shrimp powder for later use; dry commercially available seaweed at 110°C for 5 minutes, then use a food grinder to make seaweed powder for later use; wash the herbs After draining, chop and set aside;

[0040]...

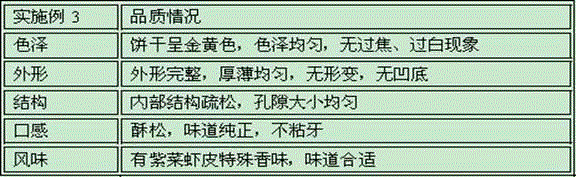

Embodiment 3

[0048] A shrimp skin seaweed biscuit, which is composed of the following raw materials in parts by weight: 220 parts of flour, 41 parts of eggs, 54 parts of shrimp skin, 35 parts of seaweed, 4.5 parts of vanilla, 10 parts of vegetable oil, 66 parts of xylitol, 0.6 parts of baking soda, yeast Powder 0.5 part, salt 0.3 part.

[0049] A kind of shrimp skin seaweed biscuit is prepared through the following steps:

[0050] 1) Crush: Wash the selected commercially available shrimp skins with water at a temperature of 20°C to remove the sediment, then add 8 parts by weight of original millet rice wine, 0.8 parts of ginger powder, and 91.2 parts of distilled water to soak for 18 minutes to remove the fishy smell. Wash, drain, and air-dry at 60°C, then use a food grinder to make shrimp powder for later use; dry commercially available seaweed at 115°C for 8 minutes, then use a food grinder to make seaweed powder for later use; wash herbs After draining, chop and set aside;

[0051] 2) K...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com