Preparation method and product of ice cream milk slurry, and ice cream containing same

A technology of ice cream and soft ice cream, applied in the field of dairy products, can solve problems such as high cholesterol content, high production cost, and poor nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

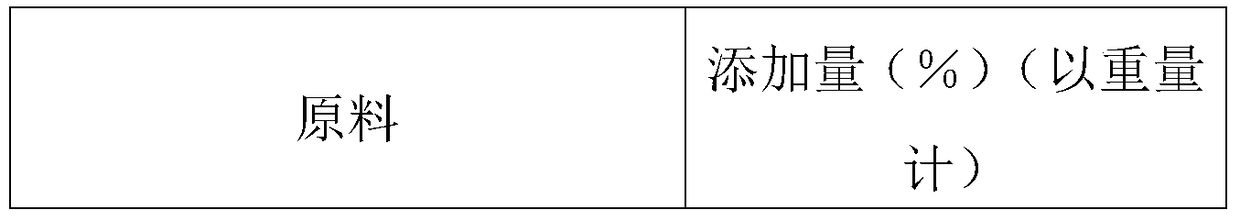

[0091] The raw material formula of table 1 embodiment 1

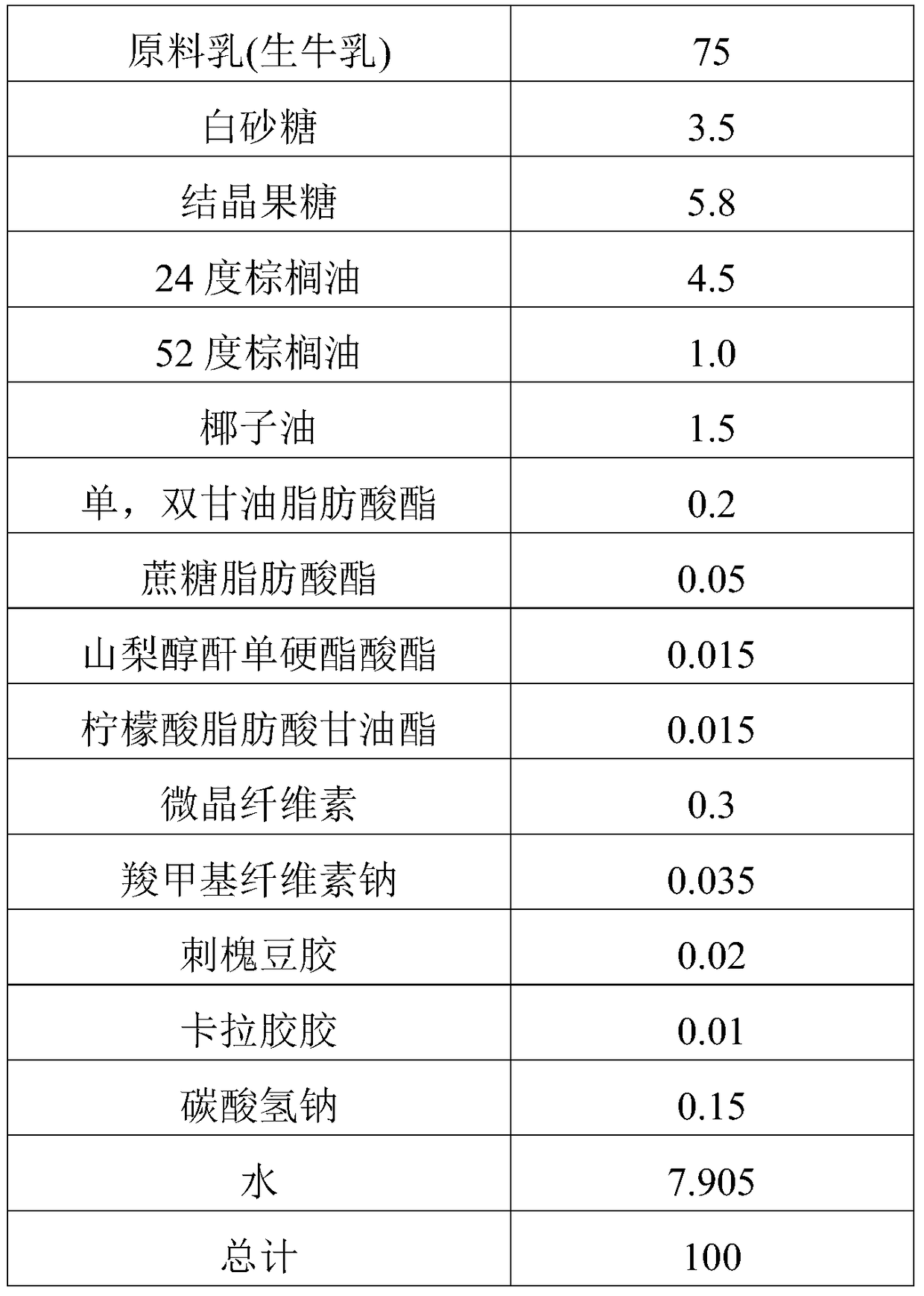

[0092]

[0093]

[0094] Preparation:

[0095] (1), raw milk (protein 2.9%, fat 3.1%) and water are heated to 85 ℃, then add described mono, diglyceride fatty acid ester, sucrose fatty acid ester, sorbitan monostearate, lemon Sour fatty acid glycerides, 24% palm oil, 52% palm oil, coconut oil, microcrystalline cellulose, sodium carboxymethyl cellulose, locust bean gum, carrageenan, white sugar, crystalline fructose, sodium bicarbonate, mixed for 15 minutes , to obtain the feed liquid; the pH of the feed liquid is 7.2;

[0096] (2) Pre-homogenize the mixed feed liquid with a homogenization temperature of 65°C and a homogenization pressure of 20Mpa, and then conduct ultra-high temperature sterilization with a sterilization temperature of 137°C and a sterilization time of 4s;

[0097] (3) Aseptically homogenize the sterilized milk slurry, wherein the homogenization temperature is 65° C., and the homogenization pres...

Embodiment 2

[0102] The raw material formula of table 3 embodiment 2

[0103]

[0104]

[0105] Wherein the raw milk formula comprises (see table 4)

[0106] Table 4 raw milk formula

[0107]

[0108] Preparation:

[0109] (1), raw milk (by mixing raw milk, skimmed milk powder and water to obtain reduced milk, wherein protein 3.5%, fat 0.3%) and water are heated to 75 ° C, add the mono-, diglyceride fatty acid ester, sucrose Fatty acid esters, sorbitan monostearate, citric fatty acid glycerides, 24% palm oil, 52% palm oil, coconut oil, microcrystalline cellulose, sodium carboxymethyl cellulose, locust bean gum, karaage Glue, white granulated sugar, and sodium bicarbonate were mixed, and stirred for 40 minutes to obtain a feed liquid; the pH of the feed liquid was 7.0;

[0110] (2) Pre-homogenize the mixed feed liquid, the homogenization temperature is 75°C, the homogenization pressure is 20Mpa, and then perform ultra-high temperature sterilization, the sterilization temperature...

Embodiment 3

[0116] The raw material formula of table 6 embodiment 3

[0117]

[0118] Wherein the raw milk formula includes (see table 7)

[0119] Table 7 Raw milk formula

[0120]

[0121]

[0122] Preparation:

[0123] (1), raw milk (reconstituted milk obtained by mixing skimmed milk powder, cream and water, wherein protein 3.2%, fat 4.0%) and water are heated to 75 ℃, add the mono-, diglyceride fatty acid ester, sucrose fat Ester, Sorbitan Monostearate, Citrate Fatty Acid Glyceride, 24% Palm Oil, 52% Palm Oil, Coconut Oil, Microcrystalline Cellulose, Sodium Carboxymethyl Cellulose, Locust Bean Gum, Carrageenan, White sugar, fructose syrup, corn syrup, and sodium bicarbonate were mixed and stirred for 40 minutes to obtain a feed liquid; the pH of the feed liquid was 6.8;

[0124] (2) Pre-homogenize the mixed feed liquid, the homogenization temperature is 75°C, the homogenization pressure is 20Mpa, and then perform ultra-high temperature sterilization, the sterilization tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com