Preparation methods and applications for diaminebenzoxazole and copolyamide electrolyte of diaminebenzoxazole

A technology of copolyamide and aminobenzoxazole, which is applied in the field of synthesis of new benzoxazole diamine compounds and their copolyamides, can solve the problems of low mechanical properties and electrical conductivity of PEO polymer electrolytes, and achieve improved mechanical properties , high thermal stability, and the effect of improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

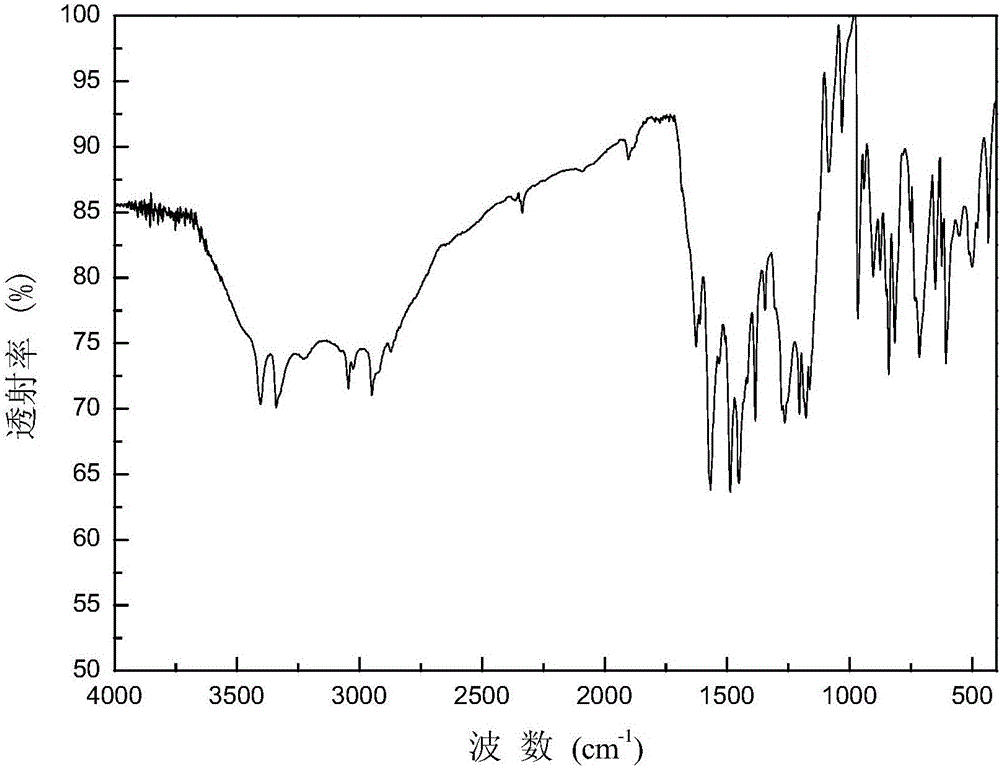

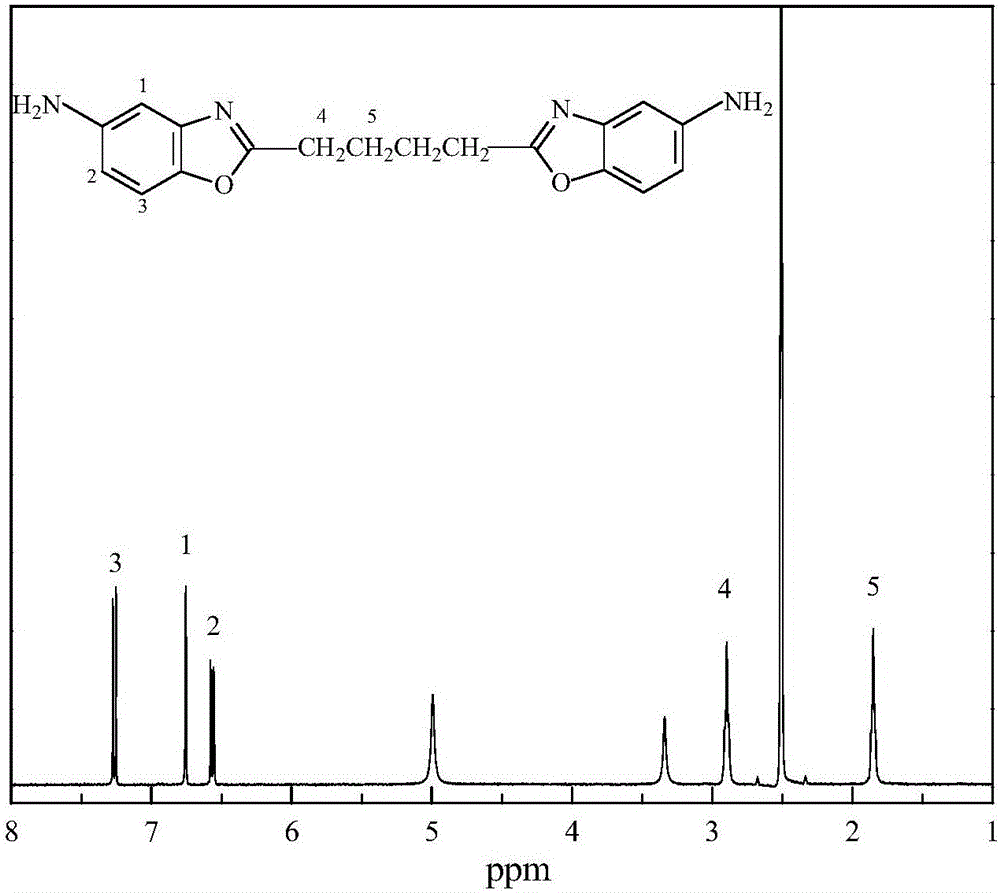

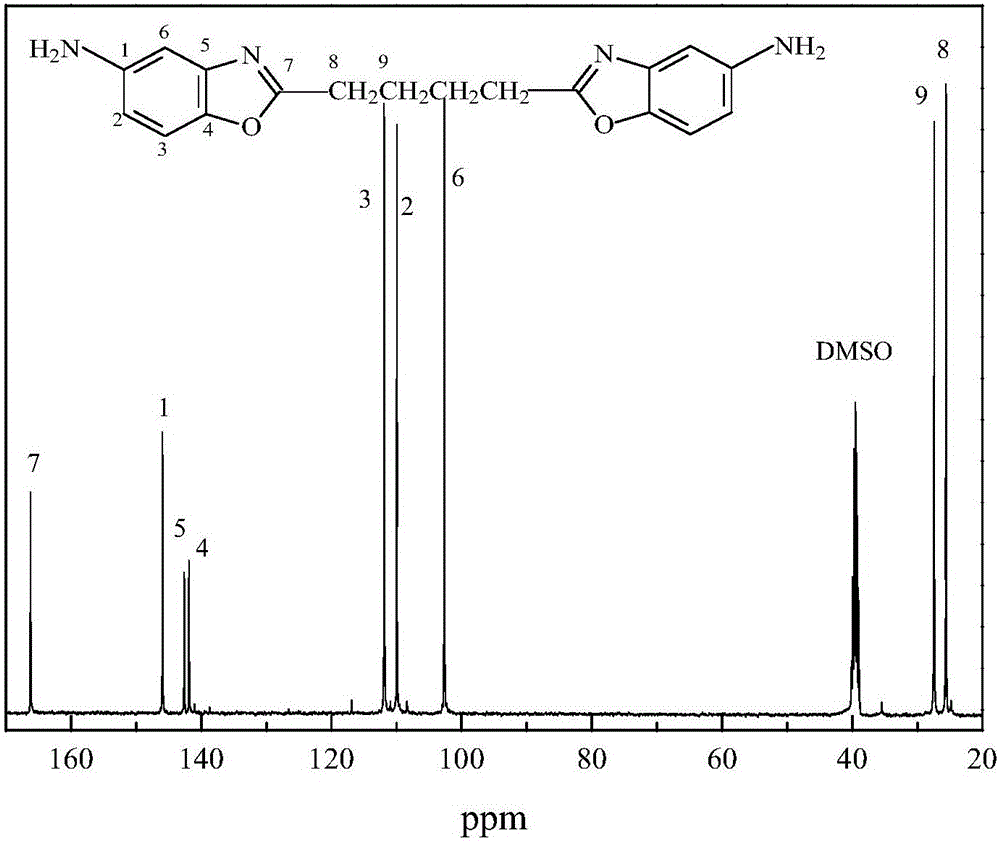

[0027] Specific embodiment 1: The preparation method of 2,2'-butylenebis[5-aminobenzoxazole] in this embodiment is realized according to the following steps:

[0028] 1. Under the protective atmosphere of inert gas, phosphoric acid and P 2 o 5 Mix well to form polyphosphoric acid solution;

[0029] 2. Weigh 2,4-diaminophenol hydrochloride and adipic acid as reaction raw materials in a molar ratio of (2.05 to 2.2): 1, and add SnCl to the polyphosphoric acid solution obtained in step 1. 2 As a reducing agent, add the reaction raw materials 2,4-diaminophenol hydrochloride and adipic acid under the condition of controlling the temperature at 140-160°C, then raise the temperature to 160-210°C, and react for 5-8 hours to obtain the reaction product;

[0030] 3. The reaction product is neutralized by sodium carbonate or sodium hydroxide, then washed with water and dried to obtain the initial product;

[0031] 4. Extract the initial product with absolute ethanol, and finally dry it...

specific Embodiment approach 2

[0034] Specific embodiment two: the difference between this embodiment and specific embodiment one is that in step one polyphosphoric acid solution, P 2 o 5 The mass concentration is 80% to 86%. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0035] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the reaction raw material in step 2 accounts for 13% to 16% of the mass of the polyphosphoric acid solution. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Charge and discharge specific capacity | aaaaa | aaaaa |

| Specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com