A kind of oil agent and preparation method thereof

A technology of oil agent and mineral oil, which is applied in textiles and papermaking, fiber treatment, fiber type, etc., can solve problems such as changes that cannot change the characteristics of oil agents, and achieve the effects of improving smoothness, saving energy, and improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

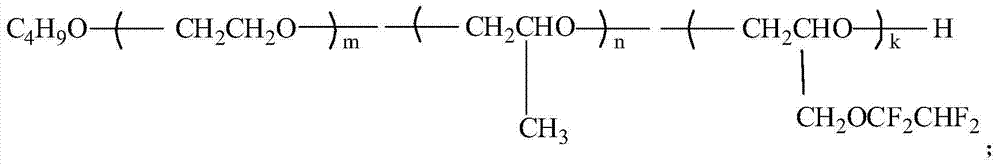

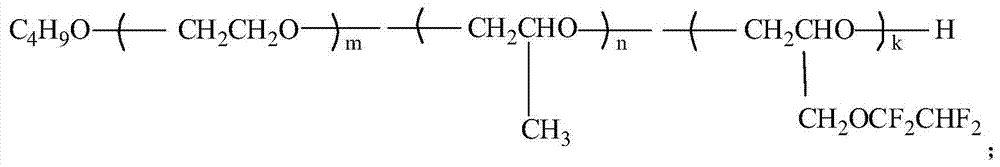

[0040]A preparation method of an oil agent, the steps are: blending the initiator butanol and strong alkali potassium hydroxide, then heating up to 105°C, and then adding uniformly mixed ethylene oxide, [(1,1,2,2 -tetrafluoroethoxy)methyl]oxirane and propylene oxide, the amount of butanol is ethylene oxide, [(1,1,2,2-tetrafluoroethoxy)methyl]epoxide 1‰ of the total mass of ethane and propylene oxide, the amount of strong base potassium hydroxide is ethylene oxide, [(1,1,2,2-tetrafluoroethoxy)methyl]oxirane and cyclo 1‰ of the total mass of oxypropylene, the amount of oxyethane, [(1,1,2,2-tetrafluoroethoxy) methyl] oxirane and propylene oxide is 10:1 by molar ratio: 20. Carry out the polymerization reaction under the protective atmosphere of nitrogen atmosphere, the reaction pressure is 0.4MPa, and after the relative molecular weight reaches 1000, the fluorine-containing polyether is obtained, the cloud point is 50°C, and the surface tension is 25dyn / cm;

[0041] Next, mix flu...

Embodiment 2

[0045] A preparation method of an oil agent, the steps are: blend the initiator butanol and strong alkali sodium hydroxide, then heat up to 125°C, and then add uniformly mixed ethylene oxide, [(1,1,2,2 -tetrafluoroethoxy)methyl]oxirane and propylene oxide, the amount of butanol is ethylene oxide, [(1,1,2,2-tetrafluoroethoxy)methyl]epoxide 5‰ of the total mass of ethane and propylene oxide, the amount of strong alkali sodium hydroxide is ethylene oxide, [(1,1,2,2-tetrafluoroethoxy)methyl]oxirane and cyclo 5‰ of the total mass of oxypropylene, the amount of oxyethane, [(1,1,2,2-tetrafluoroethoxy) methyl] oxirane and propylene oxide is 20:3 by molar ratio: 30. The polymerization reaction is carried out under the protective atmosphere of an inert gas atmosphere, the reaction pressure is 0.5 MPa, and after reaching a relative molecular weight of 4000, neutralization, adsorption, vacuum dehydration, drying and filtration are carried out to obtain fluorine-containing polyether, and i...

Embodiment 3

[0050] A preparation method of an oil agent, the steps are: blend the initiator butanol and strong alkali sodium hydroxide, then heat up to 115°C, and then add uniformly mixed ethylene oxide, [(1,1,2,2 -tetrafluoroethoxy)methyl]oxirane and propylene oxide, the amount of butanol is ethylene oxide, [(1,1,2,2-tetrafluoroethoxy)methyl]epoxide 2‰ of the total mass of ethane and propylene oxide, the amount of strong alkali sodium hydroxide is ethylene oxide, [(1,1,2,2-tetrafluoroethoxy)methyl]oxirane and cyclo 1.5‰ of the total mass of oxypropylene, the amount of ethylene oxide, [(1,1,2,2-tetrafluoroethoxy) methyl] oxirane and propylene oxide is 12:1 by molar ratio: 30. The polymerization reaction is carried out under the protective atmosphere of an inert gas atmosphere, the reaction pressure is 0.8 MPa, and after reaching a relative molecular weight of 3000, neutralization, adsorption, vacuum dehydration, drying and filtration are carried out to obtain fluorine-containing polyether...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com