Modified lithium vanadate material and modification method thereof, and application of modified lithium vanadate material in lithium ion batteries

A modified and solid technology, applied in the field of electrochemistry, can solve the problems of reducing the volume energy density of electrodes, reducing the quality of active material loading, increasing side reactions, etc., to avoid negative effects, improve kinetic performance and lithium storage capacity, The effect of simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

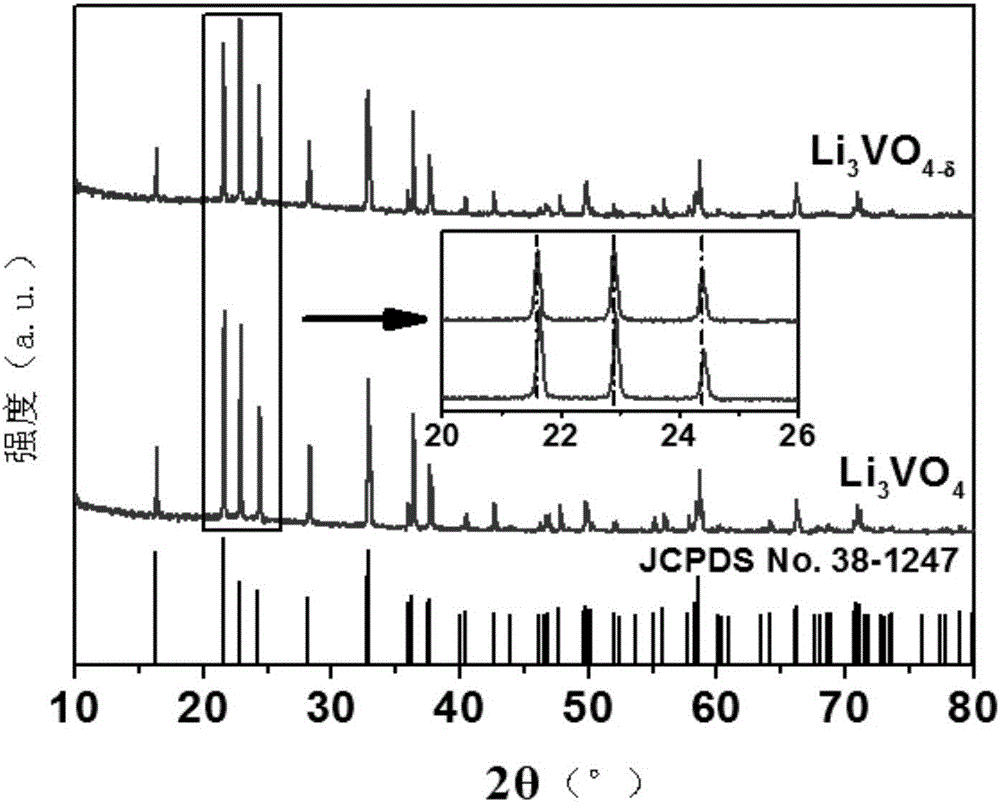

[0037] A modified Li 3 VO 4-δ The modification method of material comprises steps as follows:

[0038] (1) Take Li 3 VO 4 The sample is placed in a porcelain boat and placed in a tube furnace. The tube furnace is evacuated by a vacuum pump, and argon gas is introduced to remove oxygen. The operation is repeated three times, and then the vacuum is pumped again to keep the vacuum degree in the tube furnace at 10 -3 Pa,

[0039] (2) Heating up to 550°C, calcining at 550°C for 2 hours, and cooling to room temperature naturally to prepare modified Li 3 VO 4-δ Material.

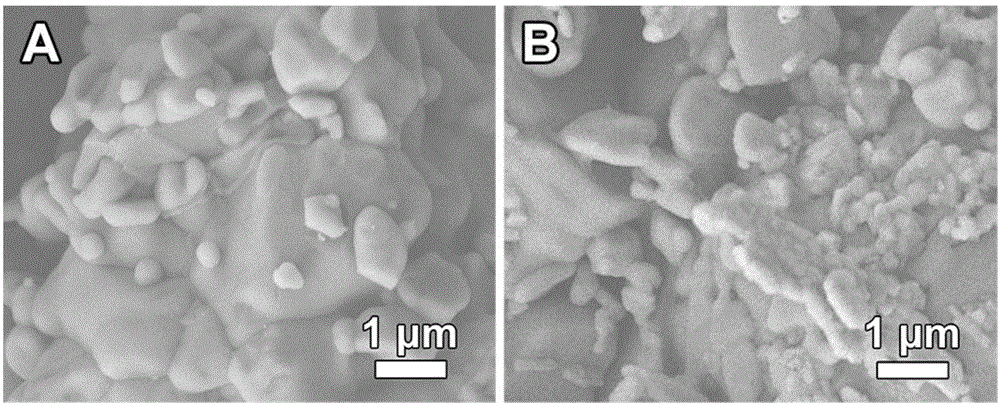

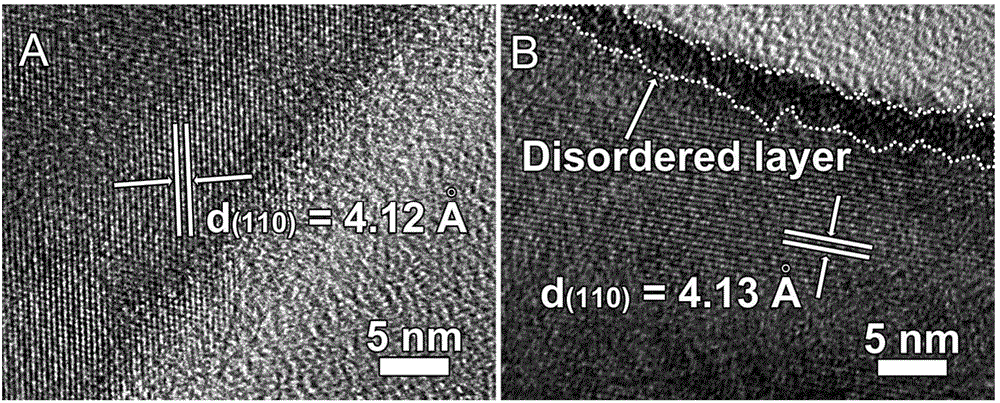

[0040] The prepared modified Li 3 VO 4-δ The interior of the material particles is in a solid crystalline state, and an amorphous layer is wrapped on the outer surface of the solid crystalline state, and the thickness of the amorphous layer is 5nm.

[0041] Control sample: Li without process of the method of the present invention 3 VO 4 The sample, that is, the unmodified Li 3 VO 4 sample.

[0042] Pe...

Embodiment 2

[0047] A modified Li 3 VO 4-δ The modification method of material comprises steps as follows:

[0048] (1) Take Li 3 VO 4 The sample is placed in a porcelain boat and placed in a tube furnace. The tube furnace is evacuated by a vacuum pump, and argon gas is introduced to remove oxygen. The operation is repeated three times, and then the vacuum is pumped again to keep the vacuum degree in the tube furnace at 10 -2 Pa,

[0049] (2) Heating up to 700°C, calcining at 700°C for 5 hours, and cooling to room temperature naturally to prepare modified Li 3 VO 4-δ Material, modified Li 3 VO 4-δ The interior of the material particles is in a solid crystalline state, and an amorphous layer is wrapped on the outer surface of the solid crystalline state, and the thickness of the amorphous layer is 6nm.

Embodiment 3

[0051] A modified Li 3 VO 4-δ The modification method of material comprises steps as follows:

[0052] (1) Take Li 3 VO 4 The sample is placed in a porcelain boat and placed in a tube furnace. The tube furnace is evacuated by a vacuum pump, and argon gas is introduced to remove oxygen. The operation is repeated three times, and then the vacuum is pumped again to keep the vacuum degree in the tube furnace at 10 -5 Pa,

[0053] (2) Heating up to 450°C, calcining at 450°C for 1 hour, and cooling to room temperature naturally to prepare modified Li 3 VO4-δ Material, modified Li 3 VO 4-δ The interior of the material particles is in a solid crystalline state, and an amorphous layer is wrapped on the outer surface of the solid crystalline state, and the thickness of the amorphous layer is 2nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com