Harmless treatment method for sodium alkali desulfurization waste solution

A technology for harmless treatment and desulfurization of waste liquid, applied in chemical instruments and methods, inorganic chemistry, alkali metal compounds, etc., can solve the problem of low utilization rate of inorganic salts, improve resource utilization rate, reduce the difficulty of salt extraction, The effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

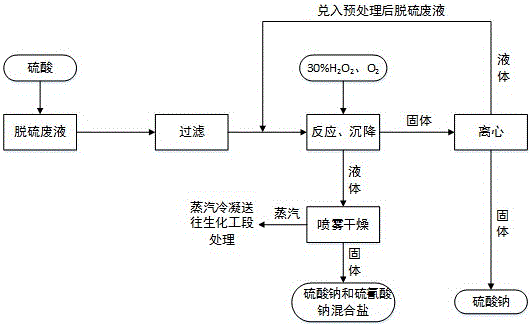

Image

Examples

Embodiment 1

[0030] The waste liquid used in this example is the desulfurization waste liquid produced by the coking gas in the coking plant using the sodium alkali wet oxidation method to remove hydrogen sulfide. Take 100mL of the desulfurization waste liquid. The main components of the desulfurization waste liquid are sodium thiocyanate and thiosulfuric acid. Sodium, sodium sulfate, sodium sulfite, sodium carbonate, sodium bicarbonate, suspended sulfur, NH 3 -N, sulfide, COD Cr .

[0031] The first step is to add sulfuric acid to 100mL of desulfurization waste liquid to adjust the pH to 2. At the same time, sulfuric acid reacts with sodium thiosulfate, sodium carbonate and sodium bicarbonate. The main chemical reactions are as follows;

[0032] Na 2 S 2 o 3 +H 2 SO 4 →H 2 SO 3 +S+Na 2 SO 4

[0033] Na 2 CO 3 +H 2 SO 4 →H 2 O+CO 2 +Na 2 SO 4

[0034] 2NaHCO 3 +H 2 SO 4 →H 2 O+2CO 2 +Na 2 SO 4

[0035] The desulfurization waste liquid was filtered by suction fil...

Embodiment 2

[0044] The waste liquid used in this example is the desulfurization waste liquid produced by the coking gas in the coking plant using the sodium alkali wet oxidation method to remove hydrogen sulfide. Take 100mL of the desulfurization waste liquid. The main components of the desulfurization waste liquid are sodium thiocyanate and thiosulfuric acid. Sodium, sodium sulfate, sodium sulfite, sodium carbonate, sodium bicarbonate, suspended sulfur, NH 3 -N, sulfide, COD Cr .

[0045] In the first step, sulfuric acid is added to 100 mL of desulfurization waste liquid to adjust the pH to 4, and sulfuric acid reacts with sodium thiosulfate, sodium carbonate, and sodium bicarbonate at the same time. The main chemical reactions are as follows;

[0046] Na 2 S 2 o 3 +H 2 SO 4 →H 2 SO 3 +S+Na 2 SO 4

[0047] Na 2 CO 3 +H 2 SO 4 →H 2 O+CO 2 +Na 2 SO 4

[0048] 2NaHCO 3 +H 2 SO 4 →H 2 O+2CO 2 +Na 2 SO 4

[0049] The desulfurization waste liquid was filtered by suc...

Embodiment 3

[0058] The waste liquid used in this example is the desulfurization waste liquid produced by the coking gas in the coking plant using the sodium alkali wet oxidation method to remove hydrogen sulfide. Take 100mL of the desulfurization waste liquid. The main components of the desulfurization waste liquid are sodium thiocyanate and thiosulfuric acid. Sodium, sodium sulfate, sodium sulfite, sodium carbonate, sodium bicarbonate, suspended sulfur, NH 3 -N, sulfide, COD Cr .

[0059] In the first step, sulfuric acid is added to 100 mL of desulfurization waste liquid to adjust the pH to 3, and sulfuric acid reacts with sodium thiosulfate, sodium carbonate, and sodium bicarbonate at the same time. The main chemical reactions are as follows;

[0060] Na 2 S 2 o 3 +H 2 SO 4 →H 2 SO 3 +S+Na 2 SO 4

[0061] Na 2 CO 3 +H 2 SO 4 →H 2 O+CO 2 +Na 2 SO 4

[0062] 2NaHCO 3 +H 2 SO 4 →H 2 O+2CO 2 +Na 2 SO 4

[0063] The desulfurization waste liquid was filtered by suc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cod value | aaaaa | aaaaa |

| Cod value | aaaaa | aaaaa |

| Cod value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com