Method for comprehensively extracting fucoxanthin and fucoidan from sargassum

A technology of fucoxanthin and fucoidan, applied in the direction of organic chemistry and the like, can solve the problems such as no disclosure of fucoxanthin and fucoidan sulfate, inability to realize technology popularization and large-scale production, low extraction efficiency and low utilization rate of raw materials, To achieve the effect of simple and easy to obtain equipment, low cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

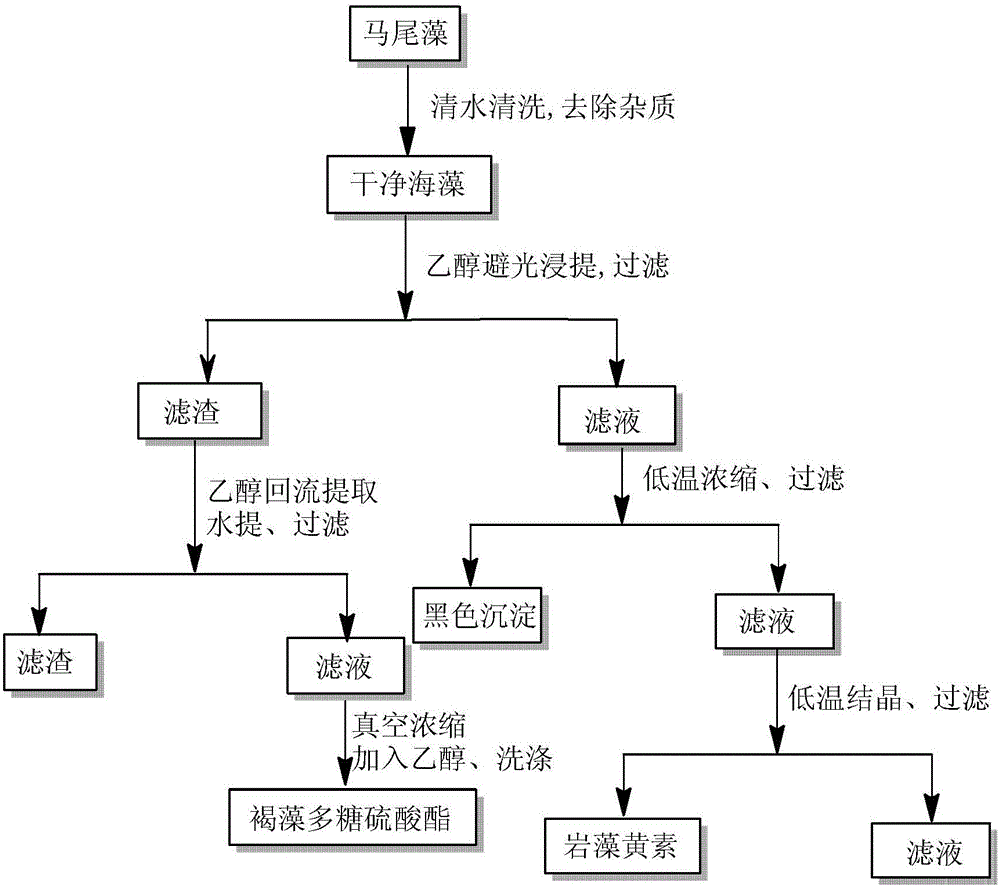

Image

Examples

Embodiment 1

[0041] Wash the fresh copper algae 3 times with water to remove surface impurities and salt, then blot the surface moisture with absorbent cotton, control the water content of the copper algae to 70%, cut it with scissors, weigh 200g copper algae, put it into a 1000mL Erlenmeyer flask, Add 600mL of 80% (V / V) ethanol aqueous solution, wrap it with tinfoil paper, put it in a shaker and extract in the dark for 4 hours, filter to obtain the filtrate and filter residue; the filtrate (A) is concentrated in vacuum at 40°C until the solution appears Black precipitate, filter; continue to concentrate until a red solid precipitates out of the solution, and the obtained red solid is high-purity fucoxanthin with a purity of 85%; The ethanol aqueous solution with a volume fraction of 80% was refluxed for 3 hours; water was added to the extracted solid, the ratio of solid to liquid was 1:5, and extracted in a water bath at 70°C for 5 hours; Centrifuge in a centrifuge under the condition of ...

Embodiment 2

[0043]Wash fresh hijiki twice with clean water to remove surface impurities and salt, then blot the surface moisture with absorbent cotton, control the moisture content of hijiki to 50%, cut it into pieces with scissors, weigh 200g hijiki, put it into a 1000mL cone Shaped bottle, add 600mL of 80% (V / V) ethanol aqueous solution, wrap it with tin foil, put it in a shaker and extract it in the dark for 1 hour, filter to obtain the filtrate and filter residue; the filtrate (A) is concentrated in vacuum at 35°C until Black precipitate appears in the solution, filter; continue to concentrate until a red solid is precipitated in the solution, and the obtained red solid is high-purity fucoxanthin with a purity of 85%; the filter residue (B) is put into a Soxhlet extractor, 60 ℃, reflux with ethanol aqueous solution with a volume fraction of 60% for 5 hours; add water to the extracted solids, the ratio of solid to liquid is 1:2, and extract in a water bath at 60 ℃ for 8 hours; filter th...

Embodiment 3

[0045] Wash fresh sea sorghum 5 times with clean water to remove surface impurities and salt, then use absorbent cotton to blot the surface moisture, control the water content of sea sorghum to 90%, cut it with scissors, weigh 200g of sea sorghum, put it into a 1000mL cone Shaped bottle, add 600mL of 80% (V / V) ethanol aqueous solution, wrap it with tin foil paper, put it in a shaker and extract it in the dark for 8 hours, filter to obtain the filtrate and filter residue; the filtrate (A) is concentrated in vacuum at 45°C until Black precipitate appears in the solution, filter; continue to concentrate until a red solid is precipitated in the solution, and the obtained red solid is high-purity fucoxanthin with a purity of 85%; the filter residue (B) is put into a Soxhlet extractor, 90 ℃, reflux with ethanol aqueous solution with a volume fraction of 99% for 1 hour; add water to the extracted solids, and extract in a 90 ℃ water bath for 3 hours; The condition is 4000r, 15min; tak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com