Preparation method of polyethylene composite material for storage tanks

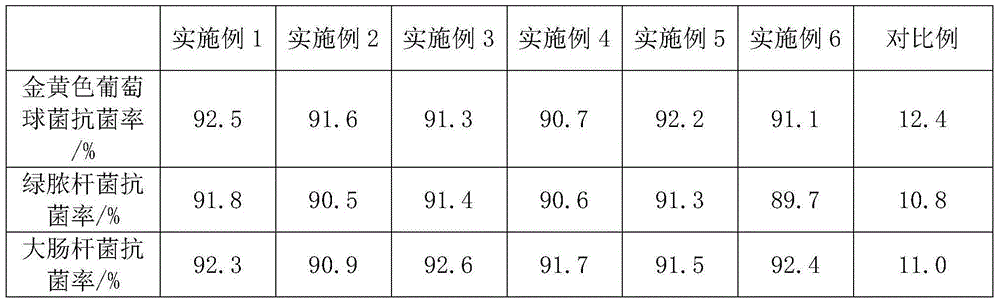

A composite material and polyethylene technology, which is applied in the field of preparing polyethylene composite materials for storage tanks, can solve problems such as poor antibacterial performance, and achieve the effects of lasting antibacterial performance, good heat resistance and improving antibacterial performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of polyethylene composite material for storage tanks, the steps are as follows:

[0027] (1) Break the Humulus leaves and dissolve them in petroleum ether. The mass volume ratio of Humulus leaves and petroleum ether is 0.02g / ml, put them in a constant temperature water bath with a temperature of 45°C for reflux extraction for 2 hours, and cool naturally to room temperature After filtering, the filter residue was dissolved in methanol for reflux extraction for 3 times, and the extraction time was 2 hours each time. Ethyl ester extraction 3 times, the combined extracts were concentrated by rotary evaporation to obtain the Humulus japonicus extract;

[0028] (2) Stir and mix the Humulus japonicus extract and titanium dioxide microspheres with a weight ratio of 4:5 for 1 hour, move to a microwave irradiator and irradiate for 3 hours to obtain a microsphere mixture;

[0029] (3) The microsphere mixture that step (2) obtains is added in the ethanol solut...

Embodiment 2

[0033] A preparation method of polyethylene composite material for storage tanks, the steps are as follows:

[0034] (1) Break the Humulus leaves and dissolve them in petroleum ether. The mass volume ratio of Humulus leaves and petroleum ether is 0.02g / ml, put them in a constant temperature water bath with a temperature of 45°C for reflux extraction for 2 hours, and cool naturally to room temperature After filtration, the filter residue was dissolved in methanol for reflux extraction for 3 times, and the extraction time was 2 hours each time. The filtrates were combined, evaporated to dryness and dissolved in dilute sulfuric acid with a mass fraction of 2%, and filtered after reflux extraction for 2.5 hours. Ethyl ester extraction 3 times, the combined extracts were concentrated by rotary evaporation to obtain the Humulus japonicus extract;

[0035] (2) Stir and mix the Humulus japonicus extract and titanium dioxide microspheres with a weight ratio of 4:5 for 1 hour, move to a...

Embodiment 3

[0040] A preparation method of polyethylene composite material for storage tanks, the steps are as follows:

[0041] (1) Break the Humulus leaves and dissolve them in petroleum ether. The mass volume ratio of Humulus leaves and petroleum ether is 0.02g / ml, put them in a constant temperature water bath with a temperature of 45°C for reflux extraction for 2 hours, and cool naturally to room temperature After filtering, the filter residue was dissolved in methanol for reflux extraction for 3 times, and the extraction time was 2 hours each time. Ethyl ester extraction 3 times, the combined extracts were concentrated by rotary evaporation to obtain the Humulus japonicus extract;

[0042] (2) Stir and mix the Humulus japonicus extract and titanium dioxide microspheres with a weight ratio of 4:5 for 1 hour, move to a microwave irradiator and irradiate for 3 hours to obtain a microsphere mixture;

[0043] (3) The microsphere mixture that step (2) obtains is added in the ethanol solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com