Anisotropic heat conduction material, and preparation method thereof

A thermally conductive material and anisotropic technology, applied in the field of anisotropic thermally conductive materials and their preparation, can solve the problem of low practicability and applicability of high thermal conductivity resins, it is difficult to ensure the directionality of thermal conductivity of materials, and thin carbon fibers are prone to occur. Coagulation and other problems, to achieve the effect of controlling heat transfer, easy control, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

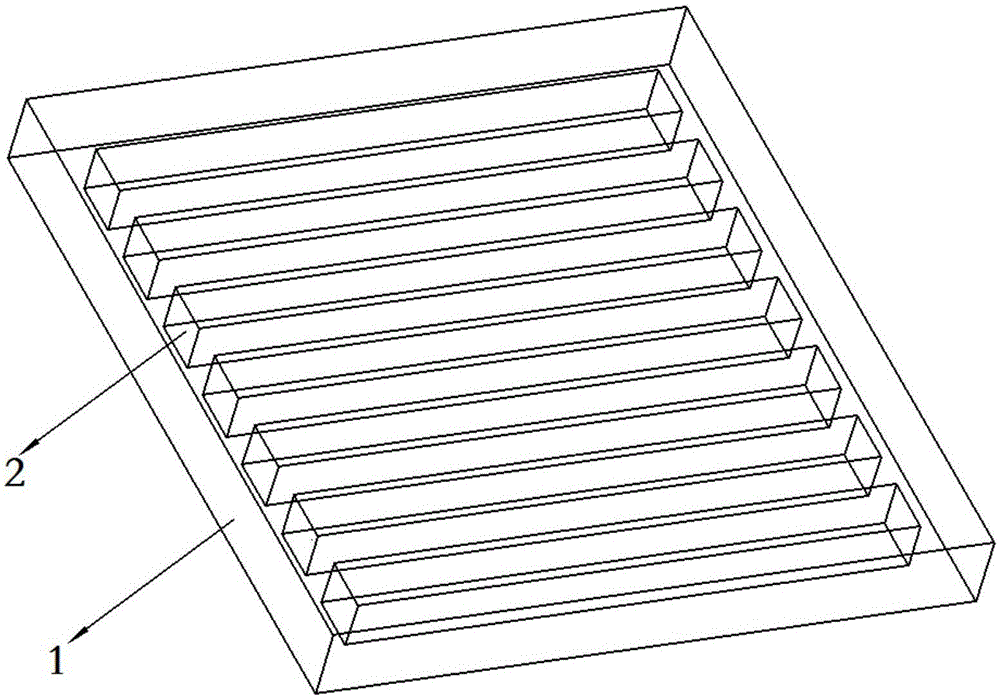

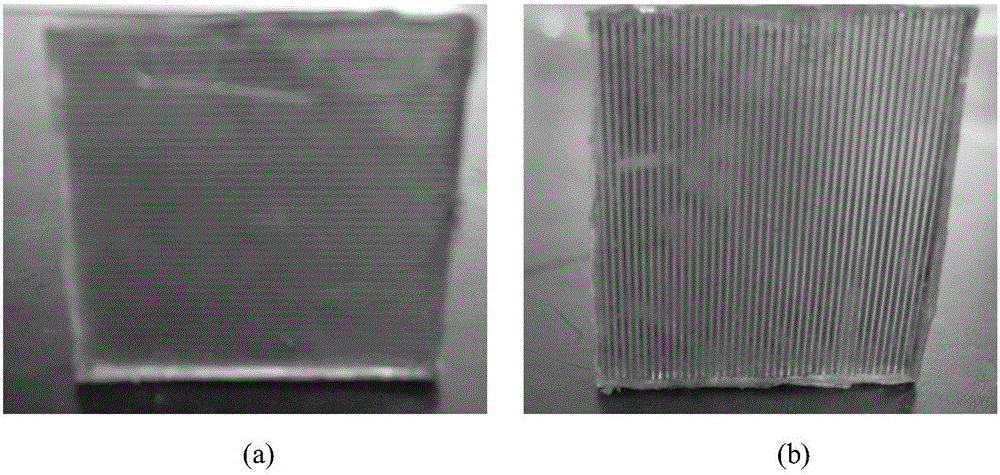

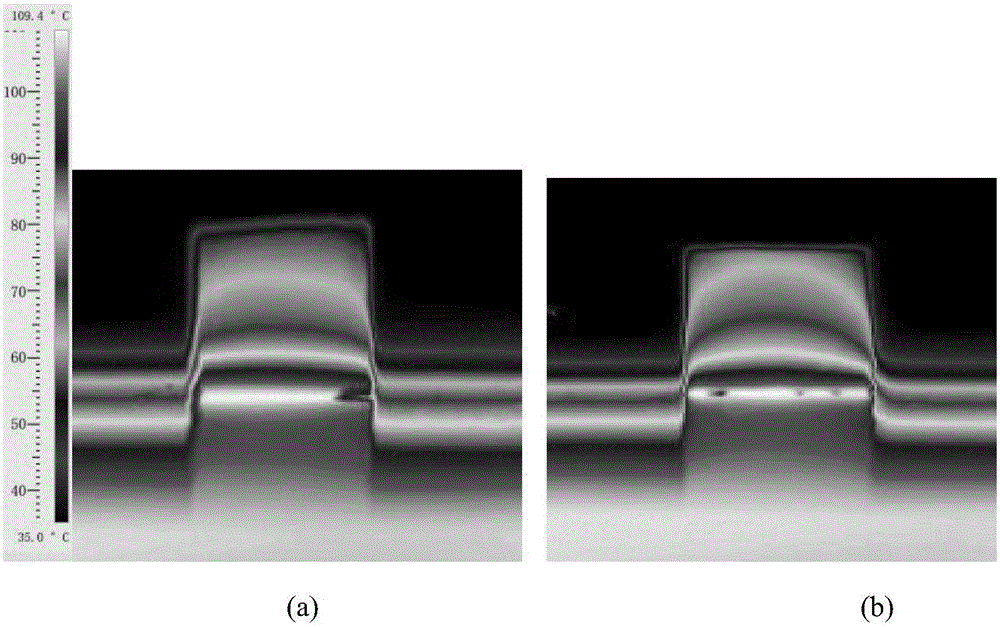

[0046] Use drawing software to design several parallel flow channels in a square frame. The flow channel layout is as follows: figure 1 . The designed flow channels will be filled with liquid metal material with high thermal conductivity. Print the film according to the above design graphics. Then use the photolithography method to use the film obtained in the above steps as a mask to produce a silicon wafer with the flow channel designed above, which is equivalent to duplicating the flow channel designed above on the silicon chip. Place the manufactured silicon wafer with flow channels in a petri dish of appropriate size, and make the side of the silicon wafer with flow channels face up. The pre-prepared liquid polymer polydimethylsiloxane is poured onto the silicon wafer. After the liquid polydimethylsiloxane is solidified, it is peeled off from the silicon wafer, and holes are punched at the entrance and exit of the flow channel, so that the liquid polymer polydimethylsi...

Embodiment 2

[0051] According to different application occasions, change the shape and layout of the flow channel. When it is necessary to control the heat transfer in the axial direction and insulate the heat in the radial direction, different liquid metal runner arrangements are required. Such as Figure 4 As shown, the liquid metal flow channels are arranged in concentric rings, and the axial and tangential thermal conductivity of the film are higher than the radial thermal conductivity, so the axial and radial anisotropic thermal conductivity film can be obtained, which can meet the heat Rapid transmission in the axial and tangential directions, and heat insulation effect in the radial direction. The height of the flow channel is 5mm, the width is 5mm, and it is filled with Ga 67 In 20.5 sn 12.5 , the liquid alloy is formulated at a heating temperature of 240°C.

Embodiment 3

[0053] Prepare as in Example 1. According to different application occasions, change the shape and layout of the flow channel. Such as Figure 5 As shown, the liquid metal flow channel is arranged in such a way that multiple straight lines radiate from one point, and the thermal conductivity in the radial direction shown in the figure is higher than that in other directions, so that the purpose of heat transfer in the radial direction can be realized.

[0054] In this embodiment, the flow channel is 3mm high and 3mm wide, and filled with GaIn 24.5 , The liquid alloy is prepared at a heating temperature of 80°C and poured at room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com