Preparation method of silver dendrite and silicon tip nanocomposite with cactus structure

A technology of nanocomposite materials and silicon needlepoints, which is applied in the field of preparation of silver dendrite/silicon needlepoint nanocomposite materials, can solve the problems that the silver dendrite nanocomposite structure cannot obtain high-density needlepoints, is inconvenient for industrial production, and has high production costs. Effects of promoting diffusion and consumption, easy operation, and fast growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

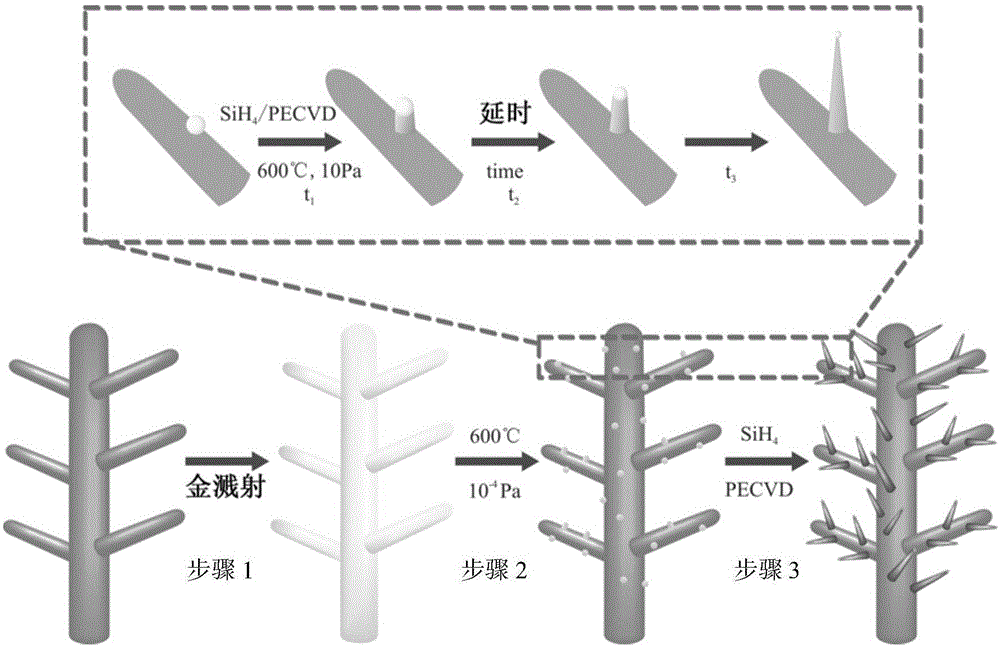

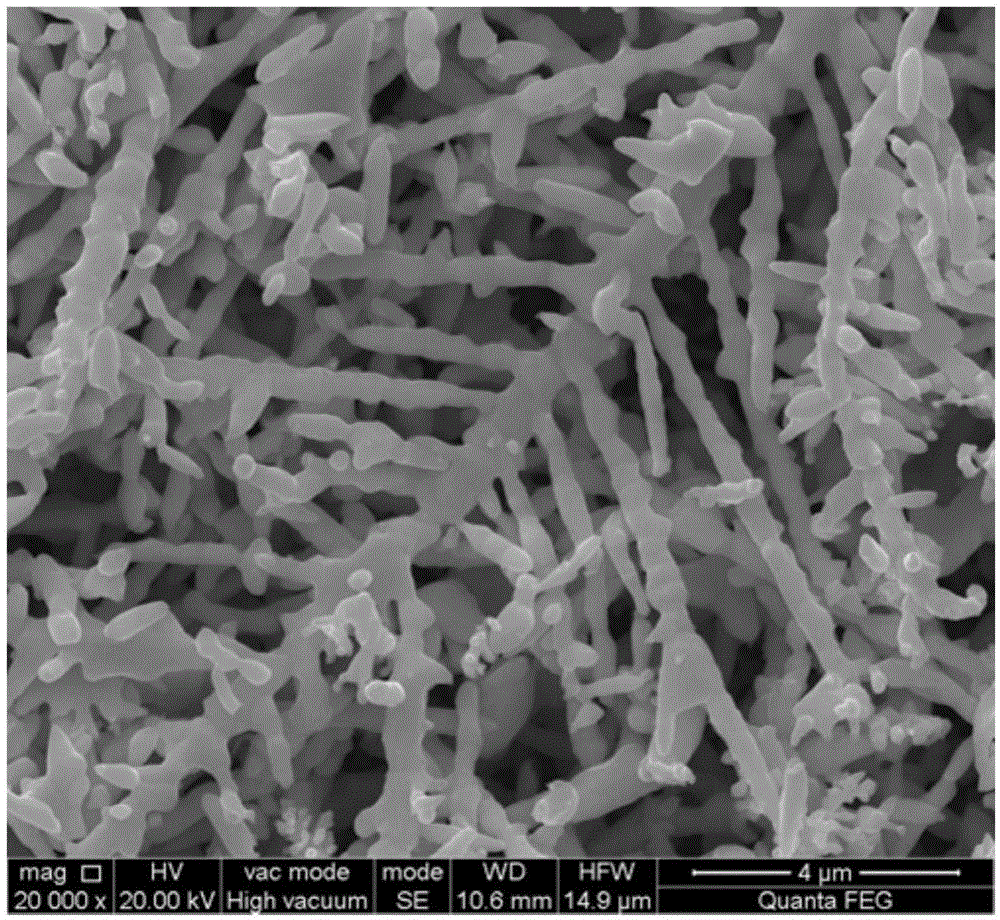

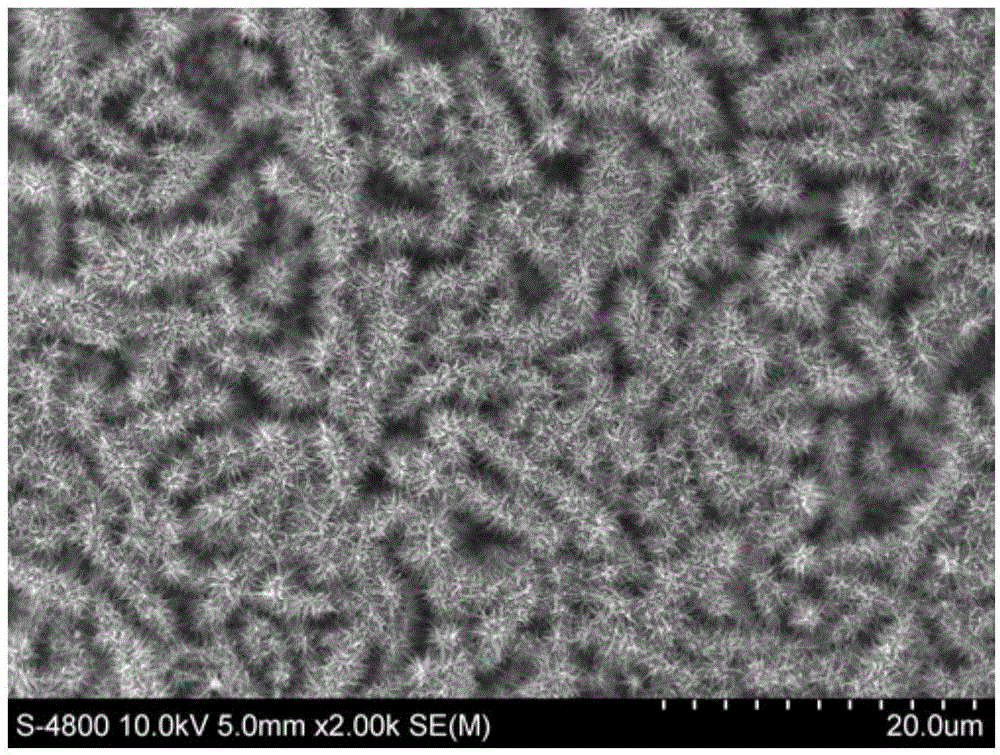

[0033]The invention provides a method for preparing silver dendrite / silicon needle tip nanocomposite material with cactus structure. This method is based on the combination of two technologies: (one), the electroless deposition technique of silver dendrite; (two), the plasma-enhanced chemical vapor deposition grafting technique of silicon tip on the surface of silver dendrite (see figure 1 ). With silicon as the substrate, silver dendrites with regular structure and more branched structures can be obtained in the mixed solution of hydrofluoric acid and silver nitrate. The obtained silver dendrite trunk is 10-20 μm long and 450-670 nm in diameter, and the branch structure is 1-4 μm long and 150-300 nm in diameter (see figure 2 ). Subsequently, using plasma-enhanced chemical vapor deposition technology, silane was used as a reaction precursor to gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com