Preparation method of tartaric acid feed additive

A feed additive and fruit acid technology, which is applied in the field of preparation of fruit acid feed additives, can solve the problems of bitterness and single organic acid of feed acidulant, and achieve the effects of good palatability, high digestibility and reduction of diarrhea rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

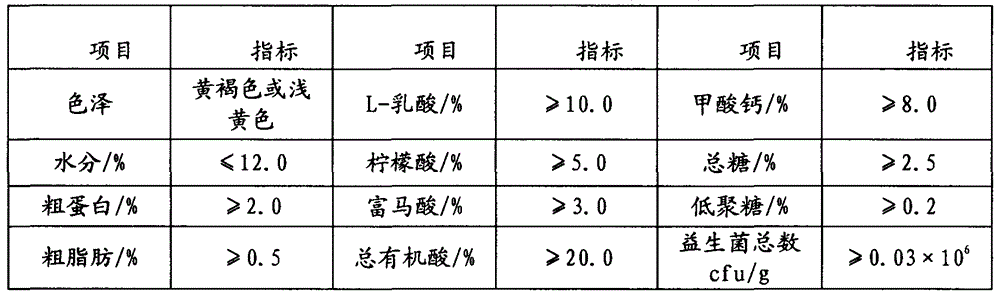

Image

Examples

Embodiment 1

[0025] After crushing 100kg of broken rice and 50kg of corn, adding 500kg of water and 50kg of molasses to make slurry, adding liquefying enzyme and glucoamylase to enzymatically hydrolyze and sterilize, the corn+broken rice+molasses enzymatic hydrolysis solution is obtained.

[0026] Weigh 300kg of corn + broken rice + molasses enzymatic hydrolysis solution, insert 6kg of lactic acid-producing Lactobacillus, 6kg of plant Lactobacillus strain, and 4kg of Lactobacillus coagulans, and carry out the same product compound strain at 32-40°C After 60-72 hours of liquid fermentation, 150-180 kg of lactic acid-rich fermentation broth is obtained after concentration.

[0027] Weigh 200kg of corn + broken rice + molasses enzymatic hydrolysis solution, add 15kg of citric acid-producing Aspergillus niger seed solution, carry out liquid fermentation of the same product single strain at 32-40°C for 72-96h, and concentrate to obtain 100-120kg fermented liquid rich in citric acid.

[0028] W...

Embodiment 2

[0031] After crushing 100 kg of broken rice, adding 400 kg of water to adjust the slurry, adding liquefying enzyme and glucoamylase for enzymatic hydrolysis and sterilization, the broken rice enzymatic hydrolysis solution is obtained. Weighing 250kg of broken rice enzymatic solution, adding 10kg of lactic acid-producing Lactobacillus plantarum seed solution, fermenting a single strain in liquid at 30-40°C for 60-72h, and concentrating to obtain 120-150kg of lactic acid fermentation solution. Weigh 250kg of broken rice enzymatic solution, add 15kg of citric acid-producing Aspergillus niger seed solution, and ferment for 72-96h with a single strain at 30-40°C, then concentrate to obtain 120-150kg of citric acid fermentation solution .

[0032] Mix 120-150kg of lactic acid fermentation broth, 120-150kg of citric acid fermentation broth, 30kg of lemons, 20kg of apples, 10kg of grapes, 5kg of figs, 5kg of tomatoes, 20kg of calcium formate and 50kg of silicon dioxide, and spray dry ...

Embodiment 3

[0034] After crushing 50kg corn and 50kg broken rice, adding 400kg water to make slurry, adding liquefying enzyme and glucoamylase to enzymolyze and sterilize, the corn+broken rice enzymolysis solution is obtained. In 500kg of corn+broken rice enzymatic solution, insert 3kg of lactic acid-producing Lactobacillus plantarum, 3kg of Lactobacillus acidophilus, 2kg of Lactobacillus coagulans, 5kg of citric acid-producing Aspergillus niger, propionic acid 2kg of Propionibacterium, after 60-72 hours of liquid fermentation of different product compound strains under the condition of 32-40°C, 120-150kg of compound acid fermentation broth rich in lactic acid, citric acid and propionic acid was obtained after concentration.

[0035] After mixing 120-150kg of compound acid fermented liquid, 50kg of lemons, 30kg of apples, 20kg of grapes, 50kg of calcium formate and 50kg of silicon dioxide, the mixture is dried to obtain 195-205kg of the fruit acid feed additive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com