Restricted access type chiral chromatography MC (monolithic column) as well as preparation method and application thereof

A technology of chiral chromatography and monolithic column, which is applied in separation methods, chemical instruments and methods, and other chemical processes. Effects on Chromatographic Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

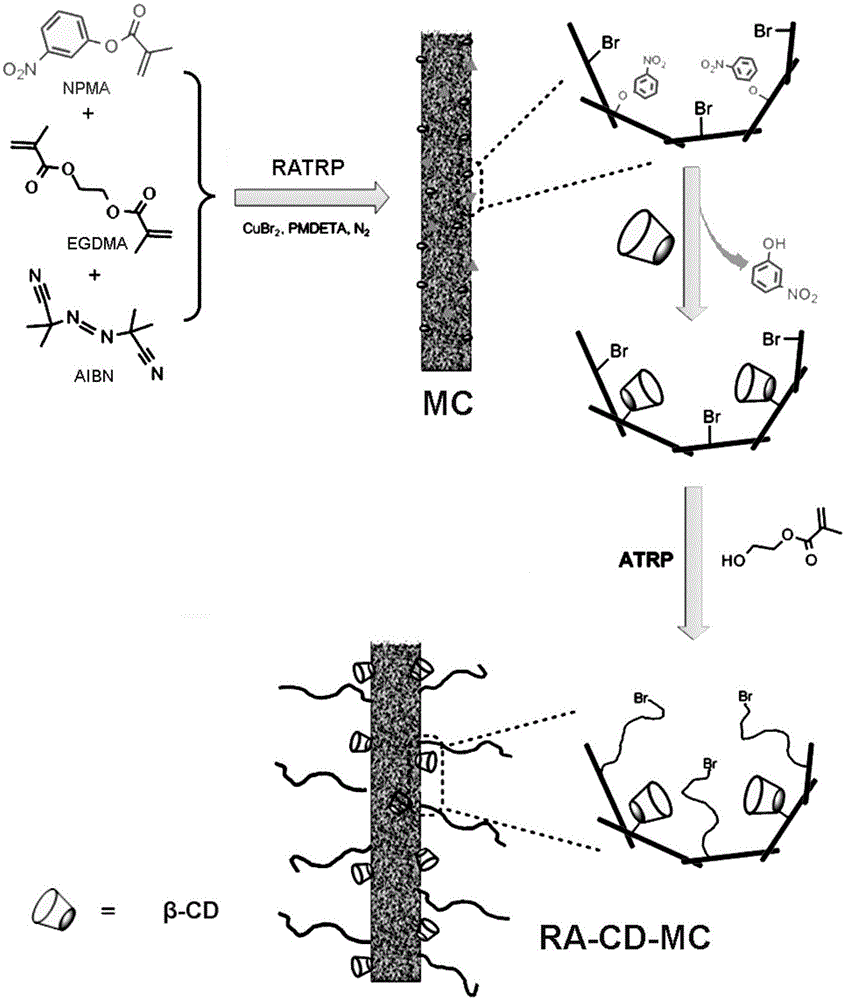

[0039]Preparation of monolithic column MC: NPMA (1.41 mmol, 292 mg) and EGDMA (1.41 mmol, 266 microliters) were added to AIBN (4.7 micromoles, 0.77 mg), PMDETA (18.8 micromoles, 4.0 microliters) and In the mixture of copper bromide (9.4 micromole, 2.1 mg) in 4 ml of acetonitrile / lauryl alcohol (9 / 1, v / v), the air in the solution was replaced by high-purity nitrogen gas, and it was injected into the stainless steel chromatographic empty column Medium (150mm x 4.6mm), sealed. React for 24 hours under 80°C water bath condition. The obtained MC monolithic column was connected to the liquid chromatography pump and rinsed with methanol.

Embodiment 2

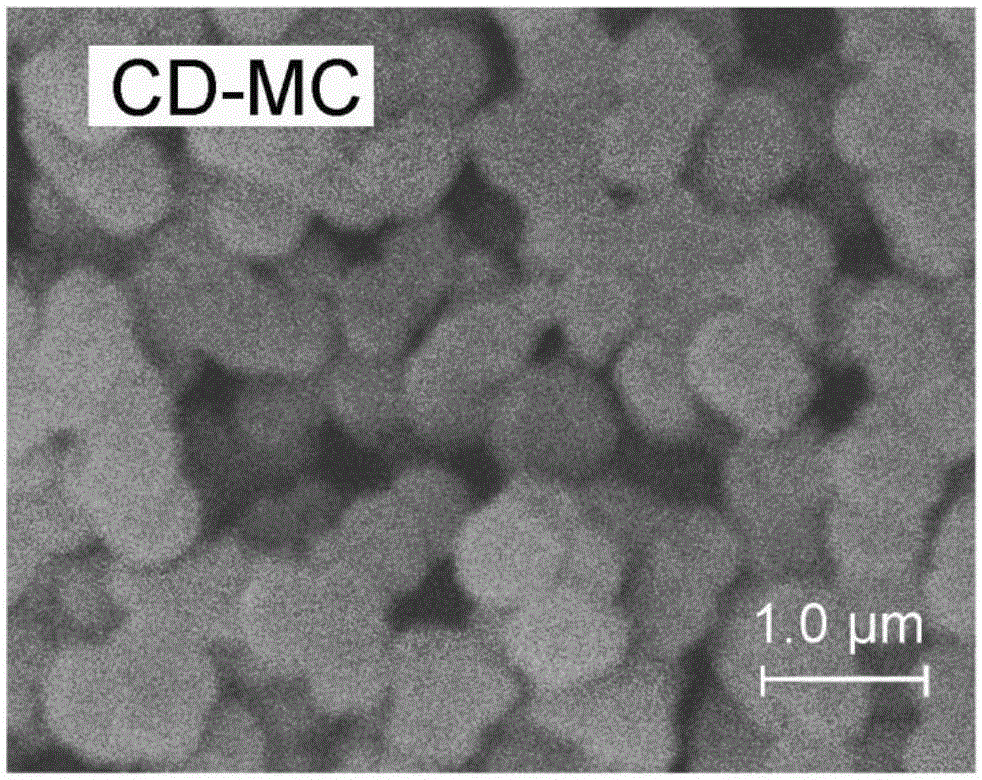

[0041] Preparation of β-cyclodextrin-modified monolithic column CD-MC: connect monolithic column MC to a liquid chromatography pump, and elute with methanol / water (1 / 9, v / v) for 30 minutes. Then the sodium carbonate buffer solution (pH 11, ion concentration 60 mmol / L) containing β-CD (17 mmol / L) was injected into the chromatographic monolithic column in a fluid manner. The reaction was carried out at 50°C for 4 hours, and the above process of elution, injection of β-cyclodextrin and heating reaction was repeated three times. Finally, methanol / water (1 / 1, v / v) was used as mobile phase to remove reaction by-products and unreacted reagents. From scanning electron microscope images ( figure 2 ), it can be seen that the polymer particles are regular and the size of the through holes between the particles is about 0.5 micron, which has good permeability and porosity.

Embodiment 3

[0043] The preparation of limited entry chiral monolithic column RA-CD-MC: will contain HEMA (0.5 mmol / liter), BIBB (6.25 micromol / liter), cuprous bromide (5 micromol / liter) and PMDETA (10 micromol / liter) of methanol solution, through high-purity nitrogen deoxygenation, packed into a 250 mm × 4.6 mm stainless steel chromatographic column, connected to the HPLC infusion pump, and connected to the CD-MC monolithic column at the outlet of the stainless steel column. After 20 minutes of infusion with methanol as the mobile phase, the CD-MC monolithic column was removed and sealed. The reaction was heated in a water bath at 60°C for 4 hours. Finally, methanol was used as the mobile phase to wash the obtained RA-CD-MC monolithic column.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com