Environment-friendly cracking-resistant and impact-resistant composite material for architectural decoration and preparation method thereof

A composite material and architectural decoration technology, applied in the field of architectural decoration materials, can solve the problems of easy-to-crack thermosetting bathroom product process, poor long-term use stability, poor impact resistance, etc., to achieve reusable materials, easy transportation, and high yield high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

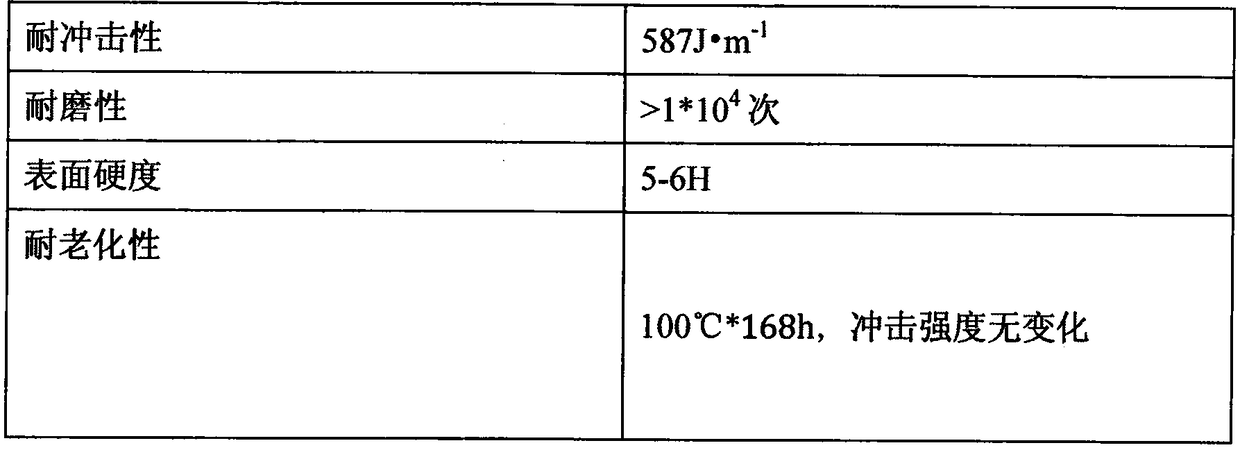

Embodiment 1

[0033] An environment-friendly cracking-resistant and impact-resistant composite material for architectural decoration, which consists of a substrate and a surface coating coated on the surface of the substrate. The preparation raw material of described matrix is by weight percentage polypropylene (Shanghai Petrochemical-T300 type) 25%; Polycarbonate (Bayer Company-Makrolon PC) 10%; Calcium carbonate 40%; Glass fiber 10%; Whitening agent (TiO 2 )5%; flame retardant (Mg(OH) 2 ) 9%; antioxidant (1010) 0.5%; anti-light aging agent (BASF-Tinuvin 622) 0.5% composition.

[0034] The preparation raw material of described surface coating consists of 20 parts by weight of polyester acrylate resin (Jining Huakai, HKP-4), 30 parts by weight of tripropylene glycol diacrylate, 35 parts by weight of pentaerythritol triacrylate, photoinitiator (di Benzophenone) 6 parts by weight, 100 parts by weight of ethyl acetate, 100 parts by weight of butyl acetate, 0.5 parts by weight of polyester ...

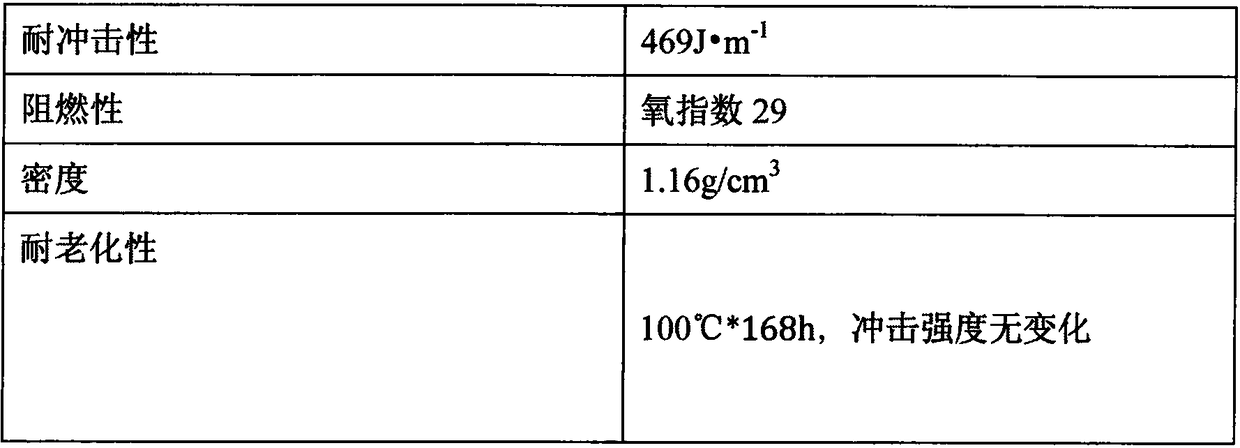

Embodiment 2

[0039] An environment-friendly cracking-resistant and impact-resistant composite material for architectural decoration, which consists of a matrix. The preparation raw material of described matrix is by weight percentage polyethylene (Sinopec-5233) 50%; Polycarbonate (Bayer company-MakrolonPC) 5%; Calcium carbonate 20%; Glass fiber 5%; Flame retardant ( Mg(OH) 2 ) 19%; antioxidant (1010) 0.5%; anti-light aging agent (BASF-Tinuvin 622) 0.5% composition.

[0040] The preparation method of the above-mentioned environment-friendly anti-cracking and impact-resistant composite material for architectural decoration is as follows: fully mix and stir each preparation raw material of the matrix in a high-speed mixer according to the formula amount, and add the mixed raw materials into the twin-screw extruder through the feeding port. In the hopper out of the machine, it is melted, blended and extruded under the condition of 130°C-180°C; the water-cooled strands are cooled in the wate...

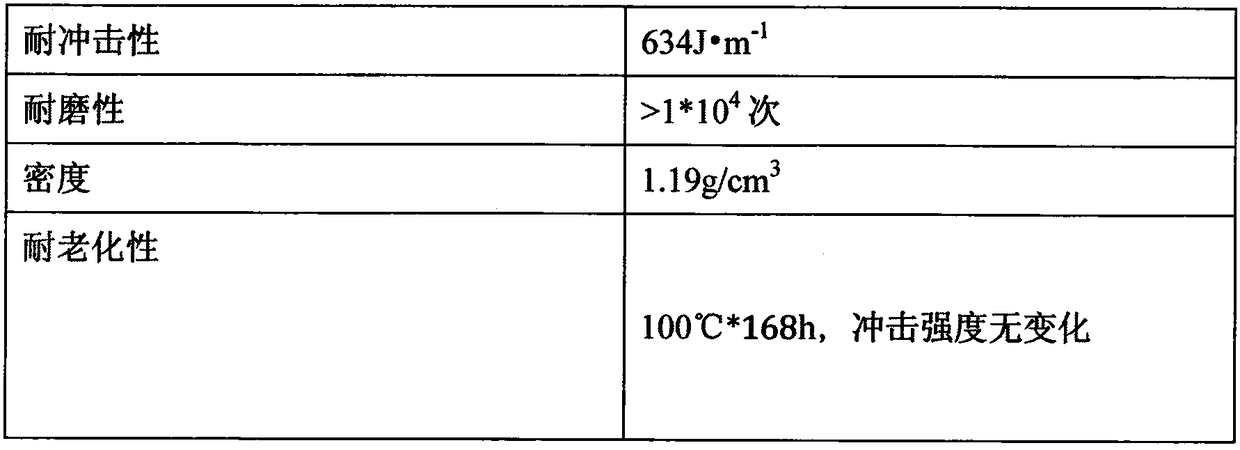

Embodiment 3

[0044] An environment-friendly cracking-resistant and impact-resistant composite material for architectural decoration, which consists of a substrate and a surface coating coated on the surface of the substrate. The preparation raw material of described matrix is by weight percent polypropylene (Shanghai Petrochemical-T300) 30%; Polyoxymethylene (DuPont-500P) 10%; Calcium carbonate 35%; Glass fiber 10%; 2 )5%; flame retardant (Mg(OH) 2 ) 9%; antioxidant (1010) 0.5%; anti-light aging agent (BASF-Tinuvin 622) 0.5% composition.

[0045] The preparation raw material of described surface coating consists of 25 parts by weight of polyester acrylic resin (Jining Huakai, HKP-4), 25 parts by weight of tripropylene glycol diacrylate, 30 parts by weight of pentaerythritol triacrylate, photoinitiator (diphenyl Methanone) 8 parts by weight, 100 parts by weight of n-butanol, 100 parts by weight of isopropanol, 0.5 parts by weight of polyester modified silicone (Shengbang, DC-193), 0.005 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com